Spinning, a metalworking process involving the deformation of a rotating metal workpiece to form axially symmetric components, has found significant applications in rail transportation. This technique, rooted in ancient craftsmanship but refined through modern engineering, enables the production of high-strength, lightweight, and precise components critical to the performance, safety, and efficiency of rail systems. From the manufacturing of wheels and axles to the fabrication of structural components and specialized parts, spinning has become integral to the rail industry. This article explores the historical evolution, technical principles, specific applications, material considerations, manufacturing advancements, economic impacts, and future prospects of spinning in rail transportation, providing a comprehensive overview supported by comparative data.

Historical Context of Spinning in Rail Transportation

The origins of metal spinning can be traced to ancient civilizations, where artisans used rudimentary tools to shape metals into functional objects. However, its industrial application in rail transportation emerged in the 19th century during the rapid expansion of railway networks. Early rail systems relied on cast or forged components, which were heavy and prone to defects. The advent of spinning allowed manufacturers to produce seamless, lightweight parts with improved mechanical properties, addressing the demands of growing rail infrastructure.

In the 1830s, as steam locomotives became the backbone of industrial transport, the need for durable wheels and axles intensified. Spinning, initially performed manually, enabled the production of wheel rims and hubs with consistent thickness and enhanced strength. By the late 19th century, mechanized spinning processes, driven by steam and later electric power, increased production efficiency, aligning with the mass production needs of rail components. The 20th century saw further advancements with the integration of hydraulic and CNC (Computer Numerical Control) spinning machines, which offered unprecedented precision and scalability.

Spinning’s role in rail transportation evolved alongside material science and engineering innovations. The transition from iron to steel alloys, coupled with spinning’s ability to form complex geometries, made it a preferred method for producing critical components. Today, spinning is a cornerstone of rail manufacturing, supporting both traditional rail systems and modern high-speed networks.

Principles of Metal Spinning

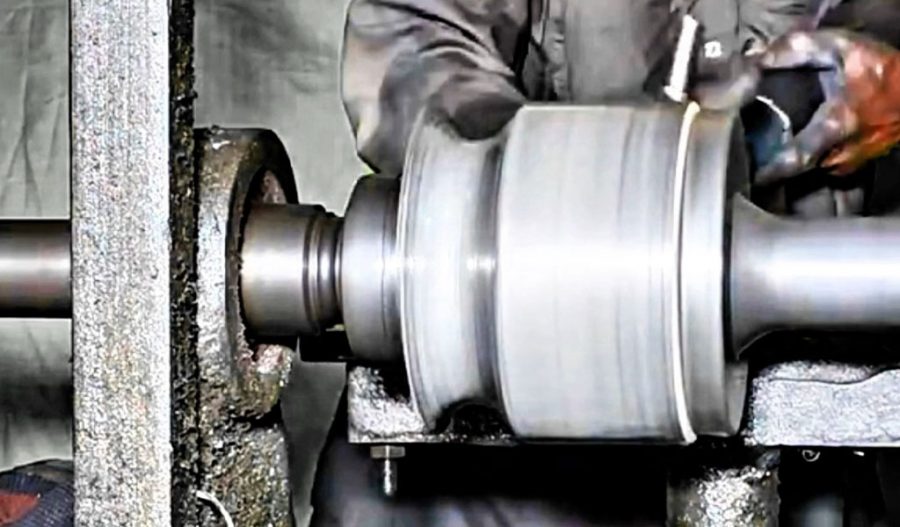

Metal spinning is a cold-forming process that involves rotating a metal blank or tube at high speed while applying localized pressure with a tool to shape it against a mandrel. The process can be categorized into conventional spinning, shear spinning, and flow forming, each suited to specific rail applications.

- Conventional Spinning: Used to form shallow, symmetrical parts like wheel hubs, this method involves gradual deformation without significant changes in wall thickness.

- Shear Spinning: Employed for conical or tapered components, such as certain axle sections, shear spinning reduces wall thickness while maintaining dimensional accuracy.

- Flow Forming: A specialized form of spinning, flow forming is used to produce high-precision, thin-walled cylindrical components like seamless railcar couplers, offering superior strength-to-weight ratios.

The spinning process begins with a flat or preformed metal blank clamped to a rotating mandrel. A roller or tool applies force, shaping the metal as it rotates. The process is highly controllable, allowing for precise wall thickness, surface finish, and dimensional tolerances. In rail transportation, spinning is valued for its ability to produce seamless components, reducing the risk of fatigue failure under cyclic loading.

Material Considerations in Spinning for Rail Applications

The choice of materials in spinning for rail components is driven by mechanical properties, cost, and compatibility with the spinning process. Common materials include:

- Carbon Steel: Widely used for wheels and axles due to its high strength and affordability. Grades like AISI 1045 are spun into wheel rims for freight trains.

- Alloy Steel: Materials like AISI 4340, with enhanced toughness and fatigue resistance, are used for high-speed rail components.

- Stainless Steel: Employed in corrosion-resistant parts like railcar fittings, particularly in coastal or high-humidity regions.

- Aluminum Alloys: Lightweight alloys like 6061-T6 are spun into structural components for high-speed trains, reducing overall vehicle weight.

- Titanium Alloys: Though expensive, titanium is used in specialized applications, such as lightweight couplers for maglev trains, due to its exceptional strength-to-weight ratio.

The table below compares the properties of materials commonly used in spinning for rail applications:

| Material | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Spinnability | Typical Applications |

|---|---|---|---|---|---|

| Carbon Steel (AISI 1045) | 530 | 7.85 | Low | High | Wheels, axles |

| Alloy Steel (AISI 4340) | 860 | 7.85 | Moderate | Moderate | High-speed rail axles |

| Stainless Steel (304) | 215 | 8.00 | High | High | Railcar fittings |

| Aluminum Alloy (6061-T6) | 276 | 2.70 | High | High | Structural components |

| Titanium Alloy (Ti-6Al-4V) | 880 | 4.43 | Very High | Moderate | Maglev couplers |

Spinnability depends on material ductility and work-hardening behavior. Ductile materials like aluminum and carbon steel are easier to spin, while high-strength alloys require advanced spinning techniques to prevent cracking.

Applications of Spinning in Rail Transportation

Spinning’s versatility makes it suitable for a wide range of rail components, from rolling stock to infrastructure. Below are the primary applications, categorized by function.

Rolling Stock Components

Wheels and Axles

Rail wheels and axles are among the most critical components, subjected to extreme cyclic loads and environmental stresses. Spinning is used to manufacture wheel rims, hubs, and axle sections, ensuring seamless construction and uniform grain structure. The process enhances fatigue resistance, critical for preventing derailments.

- Wheel Rims: Spun from carbon or alloy steel, wheel rims are formed with precise profiles to ensure compatibility with rail tracks. Spinning eliminates welds, reducing failure points.

- Wheel Hubs: Conventional spinning produces hubs with consistent thickness, improving load distribution.

- Axles: Flow forming creates seamless axle sections with thin walls, reducing weight while maintaining strength.

Couplers and Connectors

Couplers link railcars, transmitting forces during acceleration and braking. Flow forming is used to produce seamless couplers with high tensile strength. Aluminum and titanium couplers, spun for lightweight applications, are common in high-speed and maglev trains.

Suspension Components

Spun components like spring seats and damper housings are integral to rail suspension systems. These parts require precise geometries to ensure smooth ride quality and stability. Spinning allows for customized shapes, optimizing performance under dynamic loads.

Structural Components

Spinning is used to fabricate structural elements of railcars, such as end caps, roof panels, and side frames. Aluminum alloys are often spun into lightweight panels for high-speed trains, reducing energy consumption. The seamless nature of spun parts enhances structural integrity, critical for passenger safety.

Infrastructure Components

Spinning also supports rail infrastructure, including signaling and track components. For example, spun stainless steel housings protect signaling equipment from environmental damage. In electrified rail systems, spun aluminum or copper components are used in overhead catenary systems, ensuring conductivity and durability.

Specialized Applications

In maglev and hyperloop systems, spinning produces ultra-lightweight components like magnetic levitation supports and vacuum tube fittings. Titanium and advanced composites, spun with high precision, meet the stringent requirements of these cutting-edge technologies.

Manufacturing Advancements in Spinning for Rail

The integration of advanced technologies has transformed spinning in rail manufacturing, enhancing efficiency, precision, and scalability. Key advancements include:

CNC Spinning

CNC spinning machines, introduced in the late 20th century, allow for automated, high-precision forming. These machines use programmable rollers to shape complex geometries, reducing human error and enabling mass production. In rail manufacturing, CNC spinning is used for wheels, axles, and couplers, ensuring tight tolerances.

Hybrid Spinning Processes

Hybrid processes, combining spinning with forging or casting, have emerged to address specific challenges. For example, spin-forging produces wheels with enhanced grain alignment, improving fatigue life. These processes are particularly valuable for high-speed rail components.

Additive Manufacturing Integration

Additive manufacturing (3D printing) is increasingly integrated with spinning to create preforms or mandrels. This hybrid approach reduces material waste and enables the production of complex shapes that are then refined through spinning.

Automation and Robotics

Automated spinning cells, equipped with robotic arms and sensors, streamline production lines. These systems monitor process parameters in real-time, ensuring consistency and reducing defects. In rail manufacturing, automation has lowered costs and increased throughput.

The table below compares traditional and modern spinning techniques in rail manufacturing:

| Technique | Precision | Production Speed | Material Versatility | Cost | Applications |

|---|---|---|---|---|---|

| Manual Spinning | Low | Slow | Moderate | Low | Prototyping, small-scale production |

| Conventional Spinning | Moderate | Moderate | High | Moderate | Wheel hubs, structural panels |

| CNC Spinning | High | Fast | High | High | Wheels, axles, couplers |

| Flow Forming | Very High | Moderate | Moderate | High | Seamless axles, couplers |

| Spin-Forging | High | Moderate | Moderate | High | High-speed rail wheels |

Economic and Environmental Impacts

Spinning’s adoption in rail transportation has significant economic and environmental implications. Economically, spinning reduces material waste compared to casting or machining, lowering production costs. The ability to produce lightweight components also decreases fuel consumption in rail operations, reducing operating expenses.

Environmentally, spinning supports sustainability by minimizing scrap and enabling the use of recyclable materials like aluminum. Lightweight components contribute to lower carbon emissions, aligning with global efforts to decarbonize transportation. However, the energy-intensive nature of spinning, particularly for high-strength alloys, poses challenges that are being addressed through energy-efficient machines and renewable energy integration.

Challenges and Limitations

Despite its advantages, spinning in rail manufacturing faces several challenges:

- Material Constraints: High-strength alloys like titanium are difficult to spin, requiring specialized equipment and expertise.

- Tool Wear: The high forces involved in spinning cause tool wear, increasing maintenance costs.

- Scalability: While CNC spinning is scalable, manual and hybrid processes are less suited to mass production.

- Cost: Advanced spinning technologies, such as flow forming, require significant capital investment.

Ongoing research aims to address these challenges through improved tool materials, process optimization, and cost-effective automation.

Future Prospects

The future of spinning in rail transportation is promising, driven by innovations in materials, processes, and applications. Emerging trends include:

- Advanced Materials: The development of high-strength, lightweight alloys and composites will expand spinning’s applications in high-speed and maglev systems.

- Smart Manufacturing: Integration of AI and IoT (Internet of Things) in spinning processes will enable real-time quality control and predictive maintenance.

- Sustainability: Advances in energy-efficient spinning machines and recyclable materials will enhance the environmental benefits of spinning.

- Hyperloop and Maglev: As next-generation rail systems gain traction, spinning will play a critical role in producing specialized components for these technologies.

Conclusion

Spinning has revolutionized rail transportation by enabling the production of high-performance, lightweight, and durable components. From wheels and axles to structural panels and infrastructure fittings, the process has addressed the industry’s evolving needs while supporting economic and environmental goals. Advances in CNC spinning, hybrid processes, and automation have further enhanced its capabilities, positioning spinning as a cornerstone of modern rail manufacturing. As the rail industry moves toward high-speed, maglev, and hyperloop systems, spinning will continue to evolve, driven by innovations in materials, processes, and sustainability. This comprehensive exploration underscores spinning’s critical role in shaping the future of rail transportation, supported by its technical versatility and adaptability.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,