Aluminum and its alloys are widely used in aerospace, automotive, and manufacturing industries due to their favorable strength-to-weight ratio, corrosion resistance, and formability. However, under high-frequency dynamic spinning—a process involving rapid rotational deformation at frequencies typically exceeding 100 Hz—the mechanical behavior of aluminum, particularly at the microstructural level, becomes complex. This complexity arises from the interactions between dislocations and grain boundaries, which can lead to microcrack initiation and influence the material’s fatigue life and structural integrity. Understanding these phenomena is critical for optimizing the performance of aluminum components subjected to dynamic loading conditions, such as those found in high-speed rotating machinery, turbine blades, and advanced manufacturing processes like spin forming.

This article explores the dislocation activity and microcrack initiation behavior of aluminum grain boundaries under high-frequency dynamic spinning. It delves into the fundamental mechanisms governing dislocation interactions, the role of grain boundaries as both barriers and sources of dislocations, and the conditions leading to microcrack formation. By synthesizing experimental observations, theoretical models, and recent computational advances, this comprehensive review aims to provide a detailed understanding of these processes. The article is structured into sections that address the theoretical background, experimental methodologies, dislocation dynamics, grain boundary interactions, microcrack initiation mechanisms, and comparative analyses with other deformation conditions. Detailed tables are included to compare recent findings and highlight key parameters influencing the behavior of aluminum under dynamic spinning.

Theoretical Background

Dislocations in Crystalline Materials

Dislocations are linear defects in a crystal lattice that significantly influence the mechanical properties of metals. In face-centered cubic (FCC) metals like aluminum, dislocations primarily glide on {111} planes along <110> directions, facilitating plastic deformation. Under dynamic loading, such as high-frequency spinning, dislocations experience cyclic stresses that can lead to their multiplication, annihilation, or interaction with other microstructural features, such as grain boundaries. The Burgers vector, which quantifies the magnitude and direction of lattice distortion caused by a dislocation, is a critical parameter in understanding dislocation motion. For aluminum, the Burgers vector magnitude is approximately 0.286 nm, reflecting its FCC lattice structure.

Dislocation motion is governed by the resolved shear stress (RSS), which must exceed the critical resolved shear stress (CRSS) to initiate slip. In high-frequency dynamic spinning, the rapid cyclic loading imposes high strain rates, typically on the order of 10^4 s^-1 or higher, which can alter the CRSS due to strain rate sensitivity. The Peierls-Nabarro stress, which represents the lattice resistance to dislocation glide, is relatively low in aluminum due to its high stacking fault energy (SFE), approximately 160–200 mJ/m^2, promoting dislocation glide and cross-slip over twinning.

Grain Boundaries and Their Role

Grain boundaries (GBs) are interfaces between crystallites with differing orientations in polycrystalline materials. They act as barriers to dislocation motion, leading to dislocation pile-ups that generate local stress concentrations. In aluminum, GBs can be classified by their misorientation angle: low-angle grain boundaries (LAGBs, <15°) consist of arrays of dislocations, while high-angle grain boundaries (HAGBs, >15°) have more disordered atomic structures. Under dynamic spinning, the high-frequency cyclic loading exacerbates stress concentrations at GBs, potentially leading to microcrack initiation.

The interaction between dislocations and GBs is influenced by the grain size, with smaller grains increasing the GB area and thus the likelihood of dislocation-GB interactions. In ultrafine-grained (UFG) or nano-grained aluminum, the “core and mantle” model describes the GB region (mantle) as a zone of high dislocation activity, while the grain interior (core) remains relatively dislocation-free. This model is particularly relevant under high-frequency loading, where rapid deformation limits dislocation penetration into the grain interior, concentrating plastic deformation near GBs.

High-Frequency Dynamic Spinning

High-frequency dynamic spinning involves rapid rotational deformation, often used in manufacturing processes like spin forming or in components like turbine rotors. The process subjects the material to complex stress states, including tensile, compressive, and shear stresses, with frequencies typically ranging from 100 to 1000 Hz. These conditions induce high strain rates and cyclic loading, which amplify dislocation activity and GB interactions. The dynamic nature of the loading can lead to phenomena such as dynamic recovery, where dislocation annihilation and rearrangement occur, and strain localization, which may initiate microcracks.

Experimental Methodologies

Material Preparation and Characterization

To study dislocation activity and microcrack initiation in aluminum under high-frequency dynamic spinning, high-purity aluminum (e.g., 5N-Al) and commercial alloys (e.g., Al 6082, Al 7075) are commonly used. These materials are subjected to severe plastic deformation (SPD) techniques, such as rotary swaging or equal-channel angular pressing (ECAP), to control initial dislocation density and grain size. Electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM) are employed to characterize the microstructure, including grain size, misorientation, and dislocation density. For instance, EBSD provides insights into grain boundary misorientation and texture, while TEM allows direct observation of dislocation structures and GB interactions.

X-ray diffraction (XRD) is used to measure residual stresses and lattice rotations near GBs, which are critical for understanding microcrack initiation. Advanced techniques, such as high-energy X-ray diffraction (HEXRD) and in-situ TEM, enable real-time observation of dislocation dynamics during dynamic loading. These methods have revealed that dislocation emission from crack tips and GBs is a primary deformation mechanism in aluminum under high-frequency loading.

High-Frequency Dynamic Spinning Tests

Experimental setups for high-frequency dynamic spinning typically involve custom-designed rigs capable of imparting rotational speeds exceeding 6000 rpm (100 Hz). These setups apply cyclic stresses to cylindrical or disk-shaped aluminum specimens, simulating conditions in high-speed rotating components. In-situ digital image correlation (DIC) and confocal laser scanning microscopy (CLSM) are used to monitor

Low-Cycle vs. High-Cycle Fatigue

Low-cycle fatigue (LCF) involves high strain amplitudes and fewer cycles, typically leading to crack initiation at surface defects or inclusions. High-cycle fatigue (HCF), relevant to high-frequency dynamic spinning, involves lower strain amplitudes but a larger number of cycles, often exceeding 10^6. In HCF, microcrack initiation is predominantly driven by dislocation-GB interactions, as the high frequency amplifies stress concentrations at GBs.

Table 2 compares LCF and HCF in aluminum:

| Parameter | Low-Cycle Fatigue | High-Cycle Fatigue |

|---|---|---|

| Strain Amplitude | High (0.01–0.1) | Low (<0.01) |

| Cycle Count | <10^4 | >10^6 |

| Crack Initiation Mechanism | Surface defects, inclusions | GB dislocation pile-ups |

| Dislocation Activity | High, with significant recovery | High, with limited recovery |

| Fatigue Life Prediction | Paris Law applicable | Complex due to microstructural effects |

Influence of Alloying and Impurities

Alloying elements, such as magnesium or copper in Al 6082 or Al 7075, influence dislocation dynamics and microcrack initiation. Magnesium increases the SFE, promoting dislocation glide, while copper forms precipitates that act as dislocation pinning points, increasing the CRSS. Hydrogen impurities can reduce GB cohesive strength, facilitating microcrack initiation. Table 3 compares the effects of alloying and impurities:

| Alloy/Impurity | Effect on Dislocation Activity | Effect on Microcrack Initiation | Key Mechanism |

|---|---|---|---|

| Pure Al (5N) | High dislocation glide, low CRSS | Moderate, GB pile-up driven | Dislocation glide |

| Al-Mg (6082) | Increased SFE, enhanced glide | Increased due to GB sliding | GB sliding |

| Al-Cu (7075) | Precipitate pinning, high CRSS | High due to stress concentrations | Precipitate-dislocation interaction |

| Hydrogen | Increased dislocation emission | High due to reduced GB cohesion | Embrittlement |

Recent Advances and Computational Modeling

Molecular Dynamics Simulations

MD simulations have provided significant insights into dislocation-GB interactions and microcrack initiation under high-frequency dynamic spinning. Using EAM potentials, researchers have modeled the atomistic behavior of aluminum under cyclic loading, revealing that GBs act as dislocation sources and sinks. Simulations have shown that high-frequency loading increases the dislocation emission rate, leading to higher pile-up densities and stress concentrations at GBs.

Recent studies have also explored the role of GB structure in microcrack initiation. For instance, symmetric tilt GBs exhibit lower resistance to dislocation transmission compared to asymmetric GBs, reducing the likelihood of microcrack formation. These findings are supported by experimental observations using in-situ TEM, which show dislocation emission and absorption at GBs during cyclic loading.

Crystal Plasticity and Phase Field Modeling

Crystal plasticity finite element (CPFE) modeling has been used to study the macroscopic effects of dislocation-GB interactions. By incorporating strain gradient plasticity, CPFE models account for size effects in UFG aluminum, predicting higher yield stresses due to increased dislocation density near GBs. The phase field (PF) method, coupled with crystal plasticity, has been used to model GB premelting and dislocation dynamics under high-frequency loading, revealing the formation of SCPD regions where dislocation annihilation occurs.

Machine Learning Approaches

Machine learning (ML) techniques have been applied to predict GB susceptibility to microcrack initiation. By training models on EBSD and TEM data, researchers have identified GBs with high misorientation angles and low Schmid factors as prone to cracking. ML models have also been used to predict fatigue life by correlating dislocation density, GB misorientation, and stress concentrations with crack initiation events.

Implications for Material Design

The understanding of dislocation activity and microcrack initiation under high-frequency dynamic spinning has significant implications for material design. Strategies to enhance fatigue resistance include:

- Grain Refinement: Reducing grain size to the UFG or nanoscale regime increases GB area, dispersing stress concentrations but requiring careful control to prevent GB sliding.

- Alloying: Adding elements like magnesium or copper can tailor dislocation dynamics, but precipitate formation must be optimized to avoid excessive stress concentrations.

- Surface Treatments: Techniques like shot peening can introduce compressive residual stresses, reducing the likelihood of microcrack initiation at GBs.

- GB Engineering: Increasing the proportion of low-angle GBs through thermomechanical processing can enhance dislocation transmission, reducing pile-up-induced cracking.

Conclusion

The behavior of aluminum grain boundaries under high-frequency dynamic spinning is governed by complex interactions between dislocations, GBs, and cyclic stresses. Dislocation emission, pile-up, and annihilation play critical roles in determining the material’s fatigue life and susceptibility to microcrack initiation. Experimental techniques like EBSD, TEM, and in-situ XRD, combined with computational models like MD, CPFE, and PF, have provided deep insights into these processes. By understanding the effects of grain size, GB misorientation, alloying, and impurities, researchers can develop strategies to enhance the performance of aluminum components in high-frequency dynamic applications. The comparative tables presented in this article highlight the key differences between dynamic spinning and other loading conditions, underscoring the unique challenges posed by high-frequency cyclic loading.

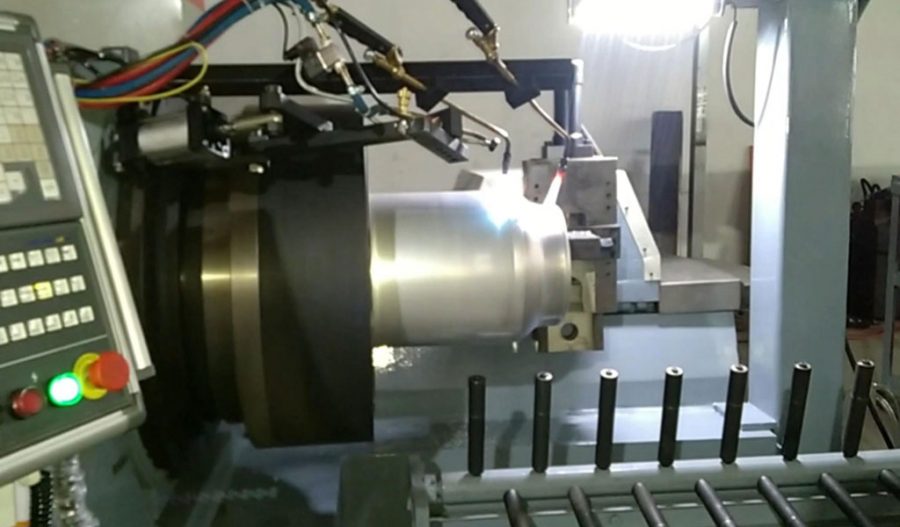

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,