CNC Metal Spinning Manufacturer

Building The Quality Suppliers a Customer Can Turn To

Being a third-generation metal spinning products suppliers & company, BE-CU spinning company understands that customers expect high quality parts delivered on time and at competitive costs. We have continually invested in our shop floor technology and our people. With these investments and thirst for Continuous Improvement, we are one of the finest production cnc spinning facilities in the china and numerous auditors have stated as much.

- Today, we employ 200 people and are growing still.

- We schedule approximately 80 primary machines – 40 spun machines – to produce across 3 shifts.

- Every month, we produce and ship over 1.1 million precision spun components to diverse industries.

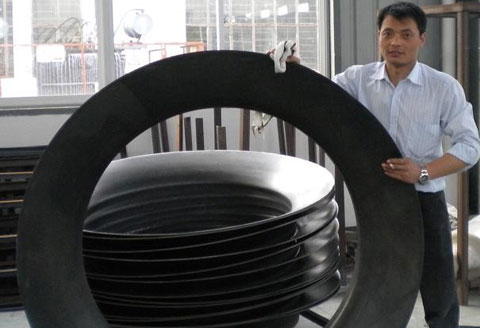

The factory can now process spinning parts with a diameter range of 80-2500mm and a length range of within 600mm. The thickness of the processed materials is stainless steel 1.5-6mm, iron 1.0-8mm, and aluminum 1.0-10mm. We also have customized thermal processing spinning machines for various rare and high-hardness metals (such as titanium alloys, molybdenum, nickel, pickaxe, lead, etc.).

Customers are welcome to visit our company for guidance. Every suggestion you have can make us better.

Our CNC Metal Spinning Capabilies

Zhongshan BE-CU metal spinning manufactuer specializes in CNC spinning, fabrication and customizing various metal spinning parts according to customer requirements. We can provide a complete set of metal spun product solutions according to the different needs of customers. It mainly produces fan accessories (air inlet, front plate), mechanical hoppers, automobile parts (mufflers, three-way catalysts, wheel hubs), venturi valves, etc., and provides high-quality spinning products to many manufacturers.

In the future, through the unremitting efforts of all our colleagues, Zhongshan BE-CU spinning manufactuer will contribute its share to promoting the development of China’s metal spinning industry.

Our cutting-edge spun machines enable us to offer an array of prototype spinning processes, including but not limited to anodizing, stamping, plating, deburring, polishing, welding, and degreasing , threading, tapping, thread milling, and more. With the help of our advanced equipment, we ensure precise and accurate results throughout the spinning process, delivering high-quality prototypes that match your exact specifications.

Superior Quality. Advanced Machinery. Highly Skilled Technicians.

BE-CU provides a range of spinning not found in other shops. When initiating a part project, our designers and technicians conceptualize and evaluate ideas and combine imagination and technology to create value. They prototype and fabricate test components and their function in your applications. Then, utilizing computer aided design and CNC spinning equipment, customer parts are fabricated at high speed with consistent quality.

A major BE-CU strength is its excellent equipment and skilled operators. Included in its dozens of spinning systems are a full range of systems including:

- Specialty machine design and built by Panasonic. Metal spinning machine Model BOSAI CNC is capable of producing spun components up to 48″ diameter. The system is equipped with robust hydraulics to handle heavy metal gauge aluminum to 1″ and 0.75″ mild steel.

- 100 HP CNC machines with a capacity of 48 inch diameter parts of 0.750 inch thick mild steel.

- CNC system has 120 inch diameter part capacity of 0.250 inch thick mild steel.

- 120 inch diameter capacity hydraulic-assisted spinning lathe.

Applying Leading-Edge Manufacturing 4.0 Technology

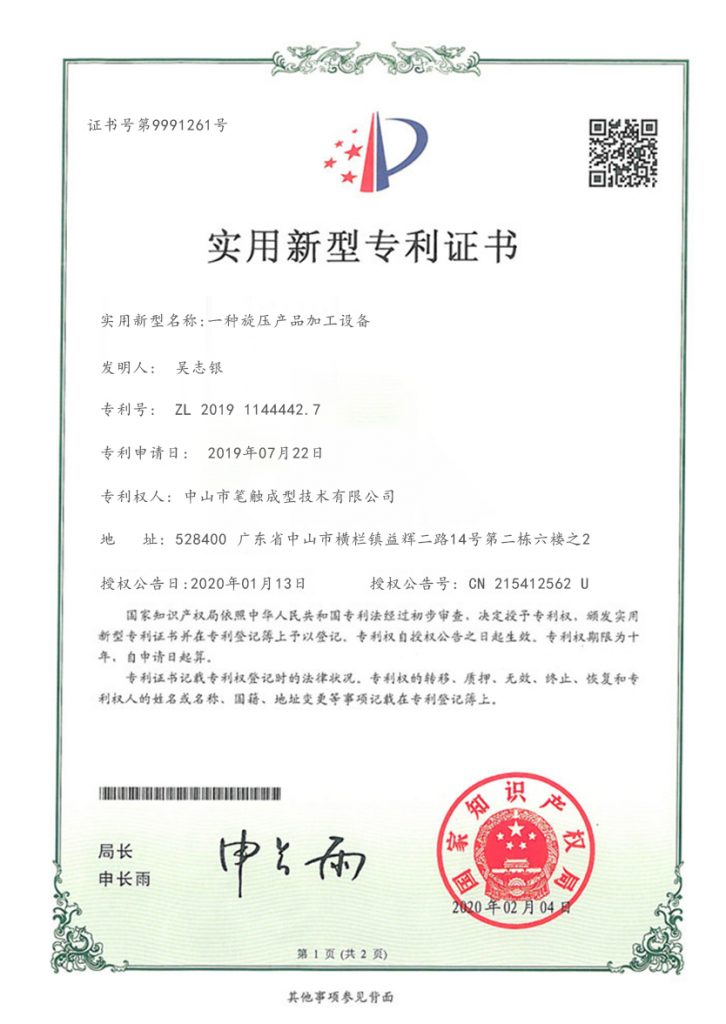

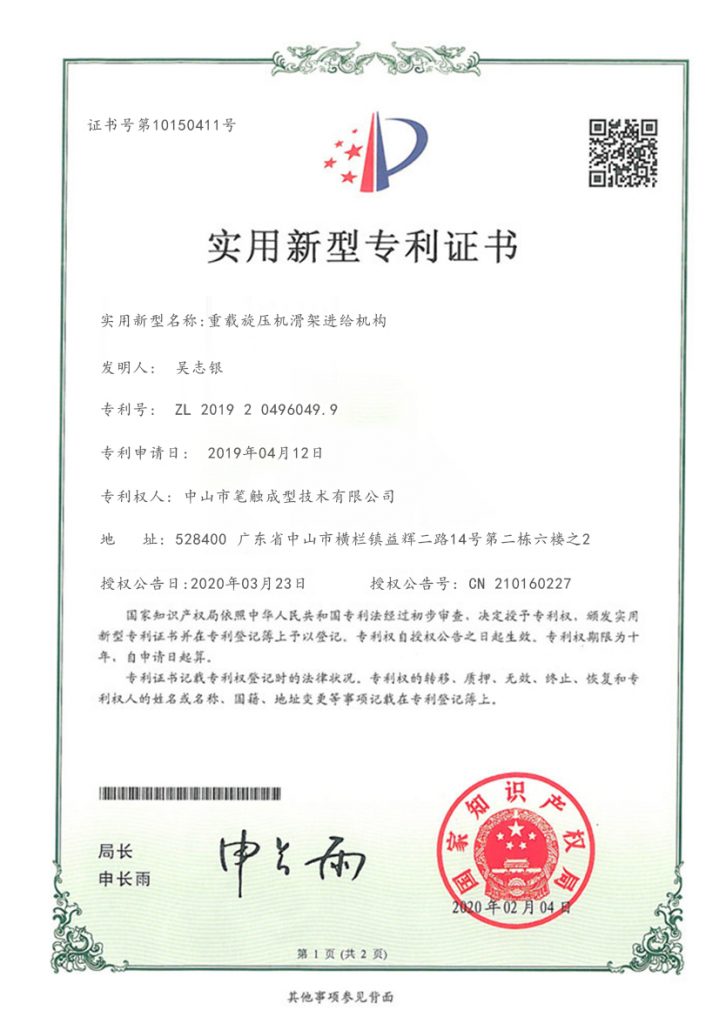

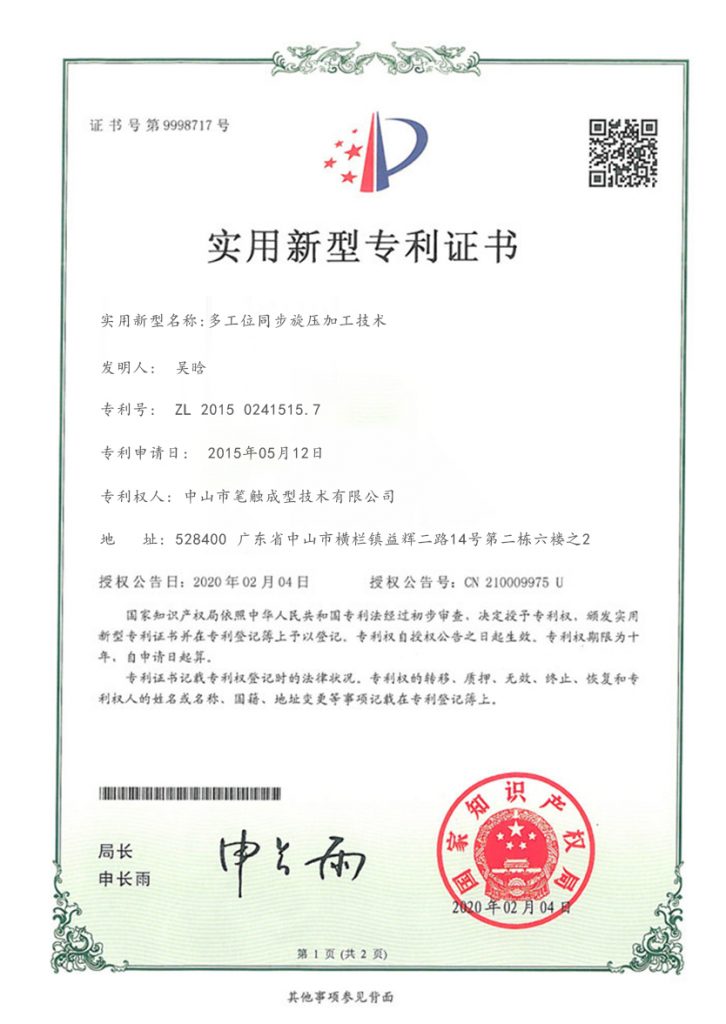

BE-CU Spinning company has a large number of professional technical certificates in spinning technology, ensuring it has deep scientific and technological strength.