Tooling Library

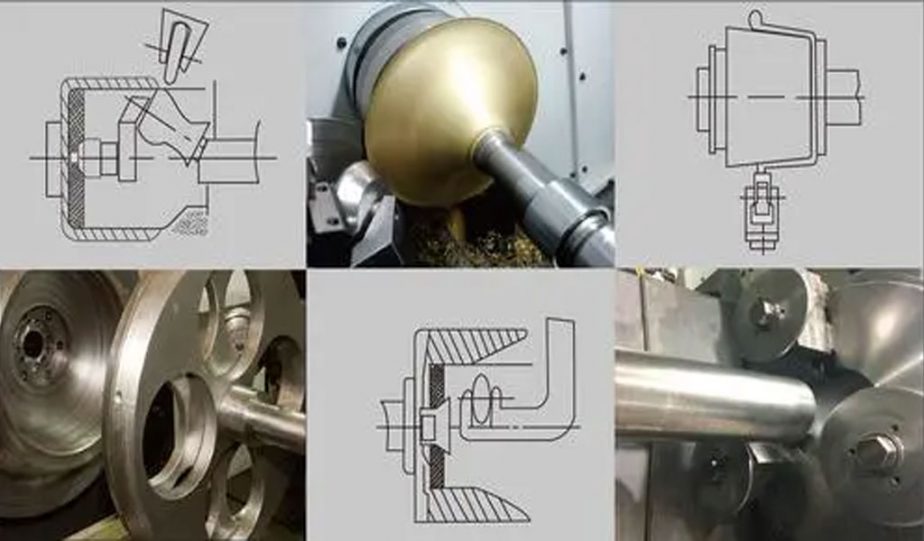

Our existing tooling library gives BE-CU spinning company a head-start on many customer part projects. This can save you time and money. Request a detailed list of our existing tooling shapes and sizes. Add BE-CU’s tool maker skills and experience to provide the most functional tooling and the result is production-ready, affordable tooling.

BE-CU produces its tooling from carbide alloys and mild steel, depending on application requirements. Both materials are less costly than heat-treated tool steel required for alternative processes such as metal stamping or deep drawing.

All tool design and production is done by BE-CU in-house. This coupled with its large tool inventory enables BE-CU to respond and deliver on a new project quickly and cost-effectively.

Tooling Material

1.45# steel 2.40Cr 3.Cr12mov 4.DC53

Special metal forming metal have been applied

- Hardox 400 GH3044 SUS310 SUS630 Incone 718 TC4

- Aluminum 2024/2A12 AL 5A06 AL 7075 Titanium Ta1

CNC Spinning Tooling Period

| 0<Diameter<300mm | Mold Material-45# | Period- 8 days |

|---|---|---|

| 0<Diameter<300mm | Mold Material-Cr12 | Period – 10 days. |

| 300<Diameter<500mm | Mold Material-45# | period- 12 days. |

| 300<Diameter<500mm | Mold Material-Cr12 | period- 16 days |

| 500<Diameter<700mm | Mold Material-45# | period- 20 days |

| 500<Diameter<700mm | Mold Material-Cr12 | period- 25 days |

| 700<Diameter<900mm | Mold Material-45# | period- 30 days |

| 700<Diameter<900mm | Mold Material-Cr12 | period- 35 days |

| Diameter>900mm | we reply you according to the drawing |

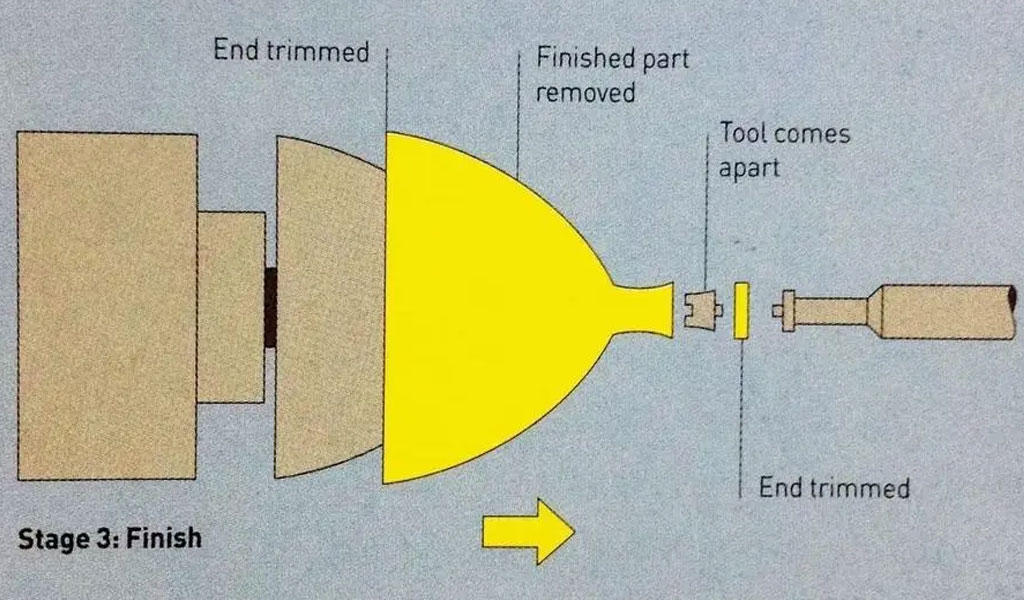

CNC Spinning Debugging Period

Simple spinning product sample : two days

Complex shape product sample : five days