Metal spinning, also known as spin forming or metal turning, is a metalworking process by which a flat metal disc or tube is rotated at high speed and formed into an axially symmetric part using tools. This technique, rooted in ancient craftsmanship, has evolved into a sophisticated method employed in various industries, including aerospace, automotive, and notably, the creation of metal sculpture art. In the context of sculpture, metal spinning offers artists a unique ability to craft intricate, seamless, and symmetrical forms that are both aesthetically compelling and structurally robust. This article explores the historical development, technical principles, artistic applications, and contemporary innovations of metal spinning in metal sculpture art, delving into its cultural significance, material considerations, and comparative advantages over other metalworking techniques.

Historical Context of Metal Spinning

Origins and Early Applications

The origins of metal spinning can be traced back to ancient civilizations, with evidence of rudimentary spinning techniques found in Egyptian, Mesopotamian, and Chinese metalwork as early as 2000 BCE. Artisans used simple lathes to shape soft metals like gold, silver, and copper into vessels, ornaments, and ceremonial objects. These early forms of spinning relied on hand-operated tools and wooden lathes, limiting the complexity and scale of the objects produced.

In the context of art, spinning was initially a utilitarian process, employed to create functional items such as bowls, chalices, and urns that doubled as decorative pieces. The seamless quality of spun metal, devoid of welds or joints, lent these objects a refined aesthetic that was highly valued in ancient cultures. For example, the Etruscan civilization (circa 700–300 BCE) produced intricately spun bronze vessels that served both practical and sculptural purposes, showcasing the potential of spinning to bridge utility and artistry.

Medieval and Renaissance Advancements

By the medieval period, metal spinning techniques had spread across Europe and Asia, with guilds of metalworkers refining the process. The introduction of foot-powered lathes in the Middle Ages allowed for greater control and precision, enabling artisans to create larger and more complex forms. During the Renaissance, the resurgence of interest in classical art forms spurred innovations in metalworking, including spinning. Artists like Benvenuto Cellini, known for their mastery of metal, incorporated spinning techniques to create ornate sculptures and decorative elements for ecclesiastical and royal commissions.

The Renaissance also marked the beginning of metal spinning as a recognized artistic medium, distinct from its industrial applications. Sculptors began experimenting with spun metal to create components for larger works, such as the bases of statues or ornamental flourishes. The ability to produce smooth, curved surfaces without visible seams made spinning particularly appealing for creating idealized forms inspired by classical Greek and Roman sculpture.

Industrial Revolution and Modernization

The Industrial Revolution (circa 1760–1840) transformed metal spinning from a craft to a mechanized process. The invention of steam-powered and later electric lathes enabled the mass production of spun metal components, which found applications in lighting fixtures, cookware, and architectural elements. While industrialization initially shifted the focus of spinning toward utilitarian objects, it also democratized access to the tools and materials needed for artistic exploration.

In the late 19th and early 20th centuries, the Arts and Crafts movement and subsequent modernist movements rekindled interest in spinning as an artistic technique. Artists sought to reclaim traditional craftsmanship in response to the perceived dehumanization of industrial production. Sculptors like Constantin Brâncuși and Alexander Calder, while not exclusively spinners, incorporated spun metal elements into their works, appreciating the technique’s ability to produce fluid, organic shapes that aligned with modernist ideals of simplicity and abstraction.

Technical Principles of Metal Spinning

Basic Mechanics

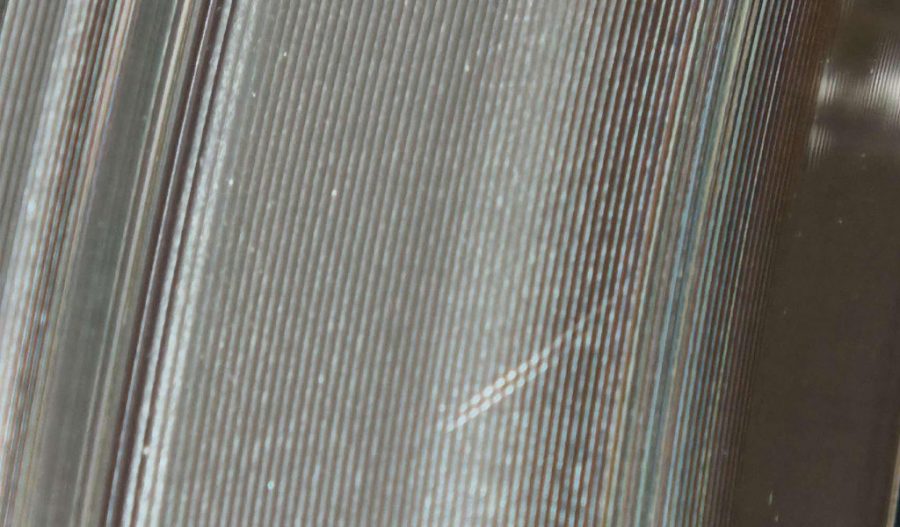

Metal spinning involves rotating a metal blank (typically a flat disc or preformed tube) at high speed on a lathe while applying localized pressure with a tool to shape the metal against a mandrel or form. The process can be performed manually, with the artisan guiding the tool by hand, or using computer numerical control (CNC) machines for precision and repeatability. The key variables in spinning include the speed of rotation, the type and thickness of the metal, the shape of the mandrel, and the force applied by the tool.

The process is typically divided into two main types: conventional spinning and flow forming. Conventional spinning involves shaping the metal without significantly altering its thickness, while flow forming (or shear spinning) reduces the thickness of the metal by stretching it over the mandrel. Both techniques are used in sculpture, depending on the desired form and structural requirements.

Materials Used in Spinning

The choice of material is critical in metal spinning, as it affects both the feasibility of the process and the aesthetic outcome. Common metals used in sculptural spinning include:

- Aluminum: Lightweight, corrosion-resistant, and highly malleable, aluminum is a popular choice for large-scale sculptures due to its ease of spinning and ability to take a polished finish.

- Copper: Valued for its warm color and natural patina, copper is often used in sculptures that emphasize organic forms or environmental interaction.

- Brass: A copper-zinc alloy, brass offers a golden hue and excellent workability, making it suitable for intricate designs.

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is favored for outdoor sculptures that require durability.

- Silver and Gold: While less common due to cost, precious metals are used in small-scale or high-value sculptures, often for their symbolic or aesthetic properties.

The following table compares the properties of these metals in the context of spinning for sculpture:

| Metal | Malleability | Corrosion Resistance | Aesthetic Qualities | Common Applications |

|---|---|---|---|---|

| Aluminum | High | Excellent | Silver-gray, polishable | Large-scale outdoor sculptures |

| Copper | High | Moderate (patina forms) | Warm reddish-brown, patinates to green | Organic forms, decorative elements |

| Brass | Moderate | Good | Golden-yellow, polishable | Intricate designs, historical reproductions |

| Stainless Steel | Moderate | Excellent | Sleek, modern, reflective | Monumental sculptures, public art |

| Silver | High | Moderate (tarnishes) | Bright, lustrous | Small-scale, high-value works |

| Gold | Very High | Excellent | Rich, warm, symbolic | Ceremonial or luxury sculptures |

Tools and Equipment

The tools used in metal spinning range from simple hand tools to advanced machinery. Traditional spinning relies on a lathe, a mandrel (a form that defines the shape of the spun part), and a variety of forming tools, such as rollers, spoons, or pointed sticks. Modern spinning often incorporates CNC lathes, which allow for precise control over complex geometries and repeatability, a feature particularly valuable in producing multiple components for large sculptures.

Lubricants are also critical in spinning, as they reduce friction between the tool and the metal, preventing galling or tearing. Common lubricants include wax, oil, or synthetic compounds, chosen based on the metal and the desired finish.

Artistic> Artistic Applications in Metal Sculpture

Symmetrical Forms and Aesthetic Appeal

One of the primary appeals of metal spinning in sculpture is its ability to produce perfectly symmetrical forms, such as spheres, cones, hemispheres, and toroidal shapes. These forms are inherently pleasing to the human eye, evoking a sense of harmony and balance. Sculptors leverage this property to create works that explore themes of unity, infinity, and perfection. For example, Anish Kapoor’s Cloud Gate (2004–2006), a monumental stainless steel sculpture in Chicago’s Millennium Park, incorporates spun elements to achieve its seamless, reflective surface, which distorts and refracts the surrounding environment in a visually captivating manner.

The smooth, continuous surfaces produced by spinning are particularly suited to minimalist and abstract sculpture, where the purity of form is paramount. Artists like Donald Judd and Richard Serra have used spun metal components to create geometric shapes that emphasize material and spatial relationships, aligning with the principles of minimalism.

Combining Spinning with Other Techniques

While spinning excels at producing symmetrical forms, sculptors often combine it with other metalworking techniques to achieve more complex or expressive results. For instance, spun components may be welded, forged, or cast to create hybrid sculptures that juxtapose smooth, spun surfaces with textured or irregular elements. This approach is evident in the works of artists like David Smith, who integrated spun metal discs with forged steel rods to create dynamic compositions that balance order and chaos.

Another common practice is the incorporation of spun elements into kinetic sculptures, where the lightweight and balanced nature of spun metal makes it ideal for moving parts. Alexander Calder’s mobiles, for example, often feature spun metal shapes that rotate and shift in response to air currents, creating a sense of fluidity and motion.

Public Art and Monumental Sculpture

Metal spinning is particularly well-suited to public art and monumental sculpture due to its ability to produce large, durable, and visually striking forms. Spun metal sculptures are often installed in urban environments, parks, or plazas, where their reflective surfaces and bold geometries engage viewers and interact with the surrounding architecture. The process’s scalability allows artists to create works ranging from small tabletop pieces to massive installations spanning dozens of meters.

A notable example is Jeff Koons’ Balloon Dog series (1994–2000), which, while primarily cast, incorporates spun metal elements to achieve the smooth, inflated appearance of the balloon forms. The reflective, mirror-like finish of these sculptures, achieved through meticulous polishing of spun stainless steel, enhances their playful yet monumental presence.

Cultural and Symbolic Significance

Symbolism of Circular and Symmetrical Forms

The circular and symmetrical forms produced by metal spinning carry rich symbolic meanings across cultures. Circles and spheres are often associated with unity, eternity, and the cosmos, making spun metal sculptures powerful vehicles for exploring philosophical and spiritual themes. In many traditions, the act of spinning itself is imbued with metaphorical significance, representing cycles, transformation, and the passage of time.

For example, in Buddhist art, mandalas—circular designs that symbolize the universe—have been reinterpreted in contemporary sculpture using spun metal to create three-dimensional forms that invite contemplation. Similarly, in Islamic art, the use of geometric patterns and symmetrical designs aligns with the aesthetic possibilities of spinning, resulting in sculptures that evoke divine order and harmony.

Spinning in Indigenous and Folk Art

In addition to its prominence in fine art, metal spinning has a place in indigenous and folk art traditions, where it is often used to create ceremonial objects, musical instruments, and decorative items. For instance, Native American artisans in the Southwestern United States have used spinning techniques to craft silver and copper vessels for ritual use, incorporating traditional motifs and symbols. These works demonstrate the versatility of spinning as a technique that can be adapted to diverse cultural contexts.

Contemporary Cultural Commentary

Contemporary sculptors often use spun metal to comment on cultural and social issues, leveraging the technique’s association with industrial production to critique consumerism, globalization, or environmental degradation. For example, Subodh Gupta, an Indian artist, creates large-scale sculptures from spun stainless steel utensils, such as pots and pans, to explore themes of domesticity, migration, and economic disparity. The reflective surfaces of these spun objects mirror the viewer and the environment, implicating them in the narrative of the work.

Innovations in Metal Spinning for Sculpture

CNC Spinning and Digital Design

The advent of CNC spinning has revolutionized the application of metal spinning in sculpture, enabling artists to achieve unprecedented levels of precision and complexity. CNC lathes, guided by computer-aided design (CAD) software, allow sculptors to create intricate, mathematically defined forms that would be impossible to produce by hand. This technology has also facilitated the integration of spinning with other digital fabrication methods, such as 3D printing and laser cutting, expanding the creative possibilities for sculptors.

For example, contemporary artist Zaha Hadid, known for her architectural sculptures, used CNC spinning to create fluid, curvilinear forms that blur the line between sculpture and architecture. Her works, such as the Liquid Glacial Table (2012), demonstrate how spinning can be used to translate digital designs into physical objects with seamless precision.

Hybrid Materials and Finishes

Recent innovations in material science have expanded the range of metals and alloys available for spinning, as well as the finishes that can be applied to spun sculptures. Titanium, for instance, is increasingly used in high-end sculpture due to its strength, light weight, and unique iridescent properties. Similarly, advancements in patination and coating technologies allow artists to achieve a wide range of colors and textures, from matte black to vibrant anodized hues.

The following table compares traditional and modern materials and finishes used in spun metal sculpture:

| Material/Finish | Properties | Applications | Advantages | Challenges |

|---|---|---|---|---|

| Aluminum (Polished) | Lightweight, reflective | Large-scale public art | Easy to spin, corrosion-resistant | Susceptible to scratches |

| Copper (Patina) | Warm color, develops green patina | Organic, historical sculptures | Aesthetically versatile | Patina process can be unpredictable |

| Stainless Steel | Durable, mirror-like finish | Monumental, modern sculptures | Low maintenance, weather-resistant | Difficult to spin due to hardness |

| Titanium | Lightweight, iridescent, corrosion-resistant | Experimental, high-end works | Unique aesthetic, strong | Expensive, requires specialized tools |

| Anodized Aluminum | Vibrant colors, durable coating | Contemporary, decorative sculptures | Customizable colors | Coating may wear over time |

Sustainable Practices

As environmental concerns become increasingly central to artistic practice, sculptors are exploring sustainable approaches to metal spinning. Recycling and upcycling metals, such as using scrap aluminum or reclaimed copper, reduce the environmental impact of sculpture production. Additionally, energy-efficient CNC lathes and low-impact lubricants are being adopted to minimize the carbon footprint of spinning processes.

Artists like El Anatsui, who creates large-scale installations from recycled materials, have experimented with spinning techniques to transform discarded metal into sculptural forms that comment on waste and resource consumption. These works highlight the potential of spinning to contribute to sustainable art practices while maintaining its aesthetic and technical strengths.

Comparative Analysis of Metal Spinning and Other Techniques

Metal spinning is one of many metalworking techniques available to sculptors, each with its own strengths and limitations. The following sections compare spinning with casting, forging, and welding, focusing on their applications in sculpture.

Metal Spinning vs. Casting

Casting involves pouring molten metal into a mold to create a solid form. While casting excels at producing complex, non-symmetrical shapes with fine detail, it often results in visible seams or surface imperfections that require extensive finishing. Spinning, by contrast, produces seamless, smooth surfaces without the need for molds, making it ideal for symmetrical forms.

| Aspect | Metal Spinning | Casting |

|---|---|---|

| Form | Symmetrical, seamless | Complex, detailed, often non-symmetrical |

| Surface Quality | Smooth, no seams | May have seams or porosity |

| Material Waste | Minimal | Moderate (sprues, risers) |

| Cost | Moderate (equipment, skill) | High (molds, melting equipment) |

| Sculptural Use | Minimalist, abstract, large-scale | Figurative, intricate, historical |

Metal Spinning vs. Forging

Forging involves shaping metal through hammering or pressing, often at high temperatures. Forging is well-suited to creating textured, organic forms with enhanced strength, but it is labor-intensive and less precise than spinning for symmetrical shapes.

| Aspect | Metal Spinning | Forging |

|---|---|---|

| Form | Symmetrical, smooth | Organic, textured |

| Precision | High (especially with CNC) | Moderate (depends on artisan skill) |

| Strength | Good (flow forming enhances strength) | Excellent (grain structure alignment) |

| Sculptural Use | Geometric, minimalist | Expressive, rustic, historical |

Metal Spinning vs. Welding

Welding joins metal pieces through heat and/or pressure, allowing for the creation of large, modular sculptures. While welding offers flexibility in combining disparate elements, the visible welds can detract from the aesthetic unity of the work, unlike the seamless forms produced by spinning.

| Aspect | Metal Spinning | Welding |

|---|---|---|

| Form | Symmetrical, seamless | Modular, assembled |

| Aesthetic | Smooth, unified | Visible joints, industrial aesthetic |

| Scalability | Large-scale possible | Highly scalable |

| Sculptural Use | Abstract, monumental | Constructivist, industrial, mixed-media |

Case Studies of Notable Spun Metal Sculptures

Anish Kapoor’s Cloud Gate (2004–2006)

Located in Chicago’s Millennium Park, Cloud Gate is a 110-ton stainless steel sculpture that exemplifies the potential of metal spinning in public art. The sculpture’s bean-like shape was achieved through a combination of spinning and advanced polishing techniques, creating a seamless, mirror-like surface that reflects the city skyline and engages viewers through its distorted reflections. The work’s monumental scale and flawless finish demonstrate the technical and aesthetic possibilities of spinning, while its public accessibility underscores the democratic potential of spun metal sculpture.

Subodh Gupta’s Very Hungry God (2006)

Indian artist Subodh Gupta’s Very Hungry God is a massive skull-shaped sculpture constructed from hundreds of spun stainless steel utensils. The work combines traditional spinning techniques with contemporary assemblage, using the reflective quality of the spun metal to comment on India’s economic disparities and global consumerism. The sculpture’s intricate construction and cultural resonance highlight the versatility of spinning as a medium for social commentary.

Zaha Hadid’s Liquid Glacial Table (2012)

Zaha Hadid’s Liquid Glacial Table is a sculptural furniture piece that pushes the boundaries of spinning through CNC technology. The table’s fluid, wave-like form, crafted from spun acrylic and metal, evokes the movement of water, showcasing the precision and elegance of modern spinning techniques. The work’s hybrid material use and architectural aesthetic illustrate the evolving role of spinning in interdisciplinary art practices.

Challenges and Limitations

Despite its many advantages, metal spinning presents several challenges for sculptors. The process requires significant skill and experience, particularly in manual spinning, where the artisan must maintain consistent pressure and speed to avoid defects like wrinkling or cracking. Even with CNC spinning, the initial setup and programming can be time-consuming and costly, limiting accessibility for emerging artists.

Material limitations also pose challenges. Hard metals like stainless steel and titanium are difficult to spin, requiring specialized tools and expertise, while softer metals like aluminum may lack the structural integrity needed for large-scale works. Additionally, spinning is inherently limited to axially symmetrical forms, restricting its applicability for sculptors seeking asymmetrical or highly detailed designs.

Environmental concerns are another consideration. The energy-intensive nature of spinning, particularly when using electric lathes or melting metals for preforms, contributes to the carbon footprint of sculpture production. Sculptors must balance these challenges with the aesthetic and technical benefits of spinning to create sustainable and impactful works.

Future Directions

The future of metal spinning in sculpture is shaped by ongoing advancements in technology, materials, and artistic practice. The integration of artificial intelligence (AI) and machine learning into CNC spinning systems promises to enhance precision and automate complex designs, potentially lowering the barriers to entry for artists. Similarly, the development of new alloys and composite materials could expand the range of forms and finishes achievable through spinning.

Interdisciplinary approaches are also likely to play a significant role. As artists increasingly blur the lines between sculpture, architecture, and design, spinning will serve as a versatile tool for creating hybrid works that challenge traditional categorizations. Collaborations between sculptors, engineers, and material scientists will further push the boundaries of what is possible, fostering innovation and experimentation.

Sustainability will remain a key focus, with artists exploring low-impact spinning techniques, recycled materials, and energy-efficient processes. Public engagement will also evolve, with interactive and participatory spun metal sculptures inviting viewers to co-create or manipulate the work, enhancing its social and cultural impact.

Conclusion

Metal spinning is a dynamic and versatile technique that has profoundly shaped the field of metal sculpture art. From its ancient origins to its modern applications, spinning has enabled artists to create seamless, symmetrical forms that captivate viewers with their aesthetic purity and technical sophistication. Its ability to produce durable, large-scale works has made it a cornerstone of public art, while its adaptability to new technologies and materials ensures its continued relevance in contemporary practice.

By combining technical precision with artistic expression, metal spinning bridges the gap between craft and fine art, offering sculptors a powerful tool for exploring form, material, and meaning. As the field evolves, spinning will undoubtedly remain a vital medium for innovation, cultural commentary, and the creation of enduring works that resonate across time and space.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,