Stainless Steel Spinning Products

Stainless steel is renowned for its strength, durability, and resistance to corrosion, making it a popular choice for a wide range of applications across various industries. Its versatility and aesthetic appeal make stainless steel an ideal material for producing high-quality components with a polished finish. Metal CNC spinning has emerged as a preferred manufacturing technique for shaping stainless steel into intricate and precise forms.

Metal CNC spinning, or computer numerical control spinning, is an advanced form of metal spinning that utilizes computer-controlled machines to shape flat metal discs or sheets into desired forms. When it comes to stainless steel, CNC spinning offers the ability to create complex shapes with precision and efficiency, maintaining the material’s inherent qualities and finish.

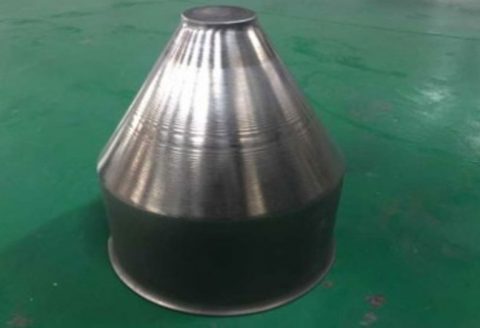

The CNC spinning process starts with a flat stainless steel blank, which can be sourced in various grades and finishes depending on the application’s requirements. The blank is clamped onto a CNC spinning machine, which rotates it at high speed. As the machine spins, specialized CNC-controlled tools and rollers apply pressure to shape the stainless steel into the desired form, such as bowls, cups, housings, or decorative pieces. This controlled and automated forming process ensures uniformity, accuracy, and consistency in the production of stainless steel components.

Stainless steel is fabricated in a wide range of different alloy formulations, with manufacturers often choosing a particular metal from the standard family of alloys that includes 301, 302, 303, 304, 316, and 347 stainless steel. At BE-CU Spinning company, we provide high-quality stainless steel metal spinning for two popular stainless steel alloys: SS 304 and SS 316.