Metal Trumpet Spinning

Metal trumpets, with their iconic curved and flared bell shape, are among the most recognizable musical instruments worldwide. The trumpet’s bell not only defines its distinctive sound but also plays a crucial role in the instrument’s resonance and projection. Crafting these intricate bell shapes requires precision, skill, and an understanding of acoustics. Metal spinning, particularly metal trumpet spinning, has become an essential technique in the manufacturing of these iconic instruments.

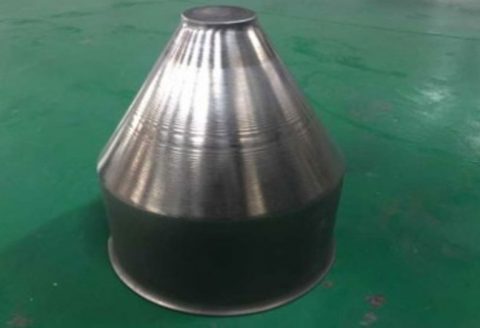

Metal trumpet spinning is a specialized form of metal spinning focused on crafting the bell-shaped components of trumpets. This process involves using a spinning lathe or CNC spinning machine to shape a flat metal disc or sheet into a trumpet bell by spinning it against a mold or mandrel.

The spinning process starts with a flat metal blank, typically made from brass, copper, or silver. The blank is clamped onto the spinning machine, which rotates it at high speed. As the machine spins, specialized tools and rollers apply pressure to shape the metal around a bell-shaped mold or mandrel. This controlled forming process ensures uniform stretching of the metal, resulting in a seamless and precise trumpet bell.