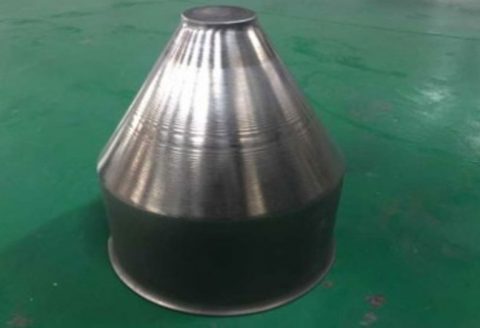

CNC Spinning Stainless Steel 304 Seat Base

CNC spinning is a manufacturing process where a flat sheet of metal is rotated at high speed and shaped over a form using a CNC-controlled tool. When working with Stainless Steel 304, a popular grade known for its excellent corrosion resistance and good formability, CNC spinning can be used to create complex, cylindrical, or conical parts like a seat base.Stainless Steel 304 has good formability, but it’s also relatively tough, which means the spinning process needs to be well-controlled to avoid work hardening or cracking.A CNC spun stainless steel 304 seat base would likely be used in environments where corrosion resistance is crucial, such as in marine, outdoor, or industrial seating.

With a range of machines, we offering precision prototype spinning capability, see prototype capabilities below

- Volume: 1-20K+ Parts

- Quoting: Within 24 hours

- Lead Time: In as fast as 10 day

- Materials: aluminum,sus,titanium,brass,copper,steel and more

- Part size: CNC spinning to 120″ diameter and 1/8″ thick.

- Standard Tolerances: +/- 0.1mm

- Price: Start from 50USD

Categories: Metal Dish-Shaped Spinning, Stainless Steel Spinning Products