Computer Numerical Control (CNC) spinning is a sophisticated metal forming process that leverages automated machinery to shape metal sheets or tubes into axisymmetric components through localized plastic deformation. This technique, an evolution of traditional manual spinning, employs programmable machine tools to achieve high precision, repeatability, and efficiency. CNC spinning is particularly valued in industries such as aerospace, automotive, and energy for producing complex geometries like conical components, which are characterized by their tapered, axisymmetric profiles. These components are integral to applications ranging from rocket nozzles and satellite dishes to exhaust cones and pressure vessel heads, where structural integrity and dimensional accuracy are paramount.

Conical components, due to their geometry, pose unique challenges in manufacturing. The tapering profile induces non-uniform stress and strain distributions during forming, which can lead to defects such as wrinkling, thinning, or cracking if not properly managed. The regulation of stress distribution in CNC spinning of conical components is thus a critical area of study, encompassing material behavior, process parameters, tooling design, and control strategies. This article provides a comprehensive exploration of the mechanisms governing stress distribution in CNC spinning of conical components, delving into theoretical foundations, experimental insights, and practical applications. Detailed comparisons of recent research findings are presented in tables to elucidate key trends and advancements.

Fundamentals of CNC Spinning

Overview of the CNC Spinning Process

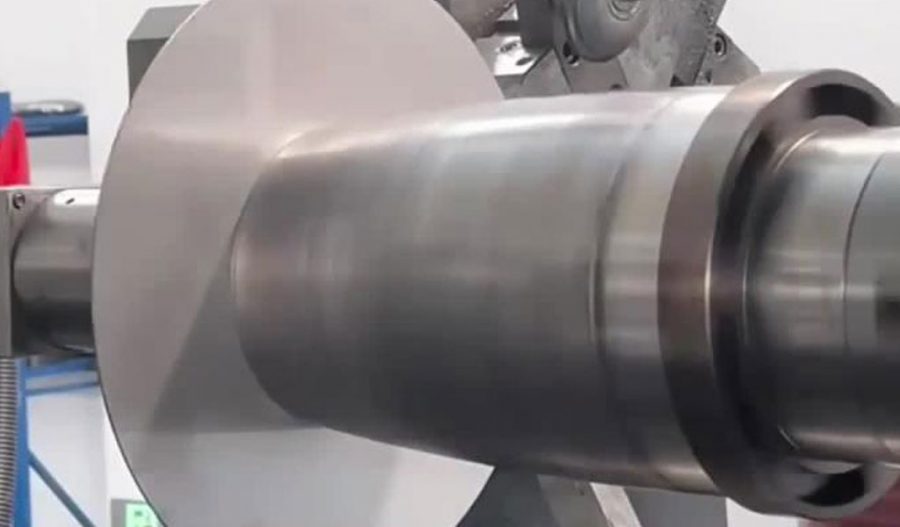

CNC spinning involves the incremental deformation of a rotating metal blank (typically a sheet or tube) against a mandrel or form tool, guided by precise computer-controlled movements. The process is classified into two primary types: conventional spinning and shear spinning. Conventional spinning maintains the blank’s thickness while shaping it into the desired geometry, whereas shear spinning reduces thickness to achieve specific profiles, often used for conical components. The CNC system interprets G-code and M-code instructions, generated via computer-aided design (CAD) or computer-aided manufacturing (CAM) software, to control multi-axis tool paths, spindle speeds, and feed rates.

In the context of conical components, shear spinning is predominant due to its ability to produce thin-walled, tapered structures. The blank is clamped to a rotating mandrel, and a roller tool applies localized pressure, progressively shaping the material along the mandrel’s contour. The process is inherently incremental, with deformation occurring in small, controlled regions, which distinguishes it from bulk forming methods like forging or deep drawing. This incremental nature allows for precise regulation of stress and strain, but it also introduces complexities in managing material flow and residual stresses.

Mechanics of Deformation in Conical Spinning

The deformation mechanics in CNC spinning of conical components are governed by plastic flow, where the material undergoes significant shear and tensile stresses. The conical geometry induces a gradient in deformation along the component’s surface, with greater thinning occurring at the smaller diameter end due to increased material stretching. The stress state is typically triaxial, comprising radial, circumferential, and axial components, which vary spatially and temporally during the process.

Key mechanical phenomena include:

- Plastic Flow and Strain Hardening: As the roller contacts the blank, it induces plastic deformation, causing the material to flow radially and circumferentially. Strain hardening increases the material’s yield strength, affecting subsequent deformation behavior.

- Thinning and Thickness Distribution: Shear spinning reduces wall thickness according to the sine law, where the final thickness is proportional to the initial thickness multiplied by the sine of the cone’s half-angle. Non-uniform thinning can occur due to variations in roller pressure or material properties.

- Residual Stresses: The incremental nature of spinning results in residual stresses, which can influence the component’s dimensional stability and fatigue life. Compressive residual stresses are often desirable for enhancing durability, while tensile stresses may promote cracking.

Finite element analysis (FEA) tools, such as DEFORM-3D and ABAQUS, are widely used to model these mechanics, providing insights into stress distribution, strain fields, and material flow. These simulations reveal that stress concentration is highest at the roller contact zone and near the mandrel’s smaller diameter, necessitating precise control of process parameters.

Stress Distribution in Conical Components

Theoretical Framework for Stress Analysis

Stress distribution in CNC spinning of conical components is analyzed using principles of continuum mechanics and plasticity theory. The material is typically modeled as isotropic and elastic-plastic, following constitutive models like the von Mises yield criterion or the Hill anisotropic yield criterion for anisotropic materials. The stress tensor at any point in the deforming blank comprises normal stresses (σ_r, σ_θ, σ_z) and shear stresses (τ_rθ, τ_rz, τ_θz), where r, θ, and z denote radial, circumferential, and axial directions, respectively.

The equilibrium equations, coupled with compatibility conditions and constitutive relations, govern the stress state. For conical components, the tapering geometry introduces a non-uniform stress gradient, with the following characteristics:

- Radial Stress (σ_r): Predominantly compressive at the roller contact zone due to the applied forming force.

- Circumferential Stress (σ_θ): Tensile near the outer diameter due to material stretching, transitioning to compressive stresses closer to the mandrel.

- Axial Stress (σ_z): Varies along the cone’s axis, with tensile stresses at the smaller diameter end due to material elongation.

The roller’s motion induces dynamic changes in the stress field, with peak stresses occurring at the contact point and diminishing as the roller advances. Analytical models, such as those based on the slab method or upper bound method, provide simplified approximations of stress distribution, while numerical methods like FEA offer detailed spatial and temporal resolutions.

Factors Influencing Stress Distribution

Several factors influence stress distribution in CNC spinning of conical components, including material properties, process parameters, tooling design, and boundary conditions. These are discussed below:

Material Properties

The material’s yield strength, ductility, and strain hardening behavior significantly affect stress distribution. Common materials for conical components include aluminum alloys, stainless steels, and titanium alloys, each exhibiting distinct flow characteristics. For instance, aluminum alloys (e.g., AA6061) display moderate strain hardening, while titanium alloys (e.g., Ti-6Al-4V) exhibit high strength and limited ductility, leading to higher stress concentrations.

Anisotropy, particularly in rolled sheets, influences stress distribution by introducing directional variations in mechanical properties. The Lankford coefficient (r-value) quantifies anisotropy, with higher values indicating greater resistance to thinning, which can mitigate stress concentrations but complicate material flow.

Process Parameters

Key process parameters include roller feed rate, spindle speed, roller diameter, and forming force. These parameters govern the rate and extent of deformation, directly impacting stress distribution:

- Roller Feed Rate: Higher feed rates increase deformation speed, elevating stress levels and potentially causing wrinkling or cracking. Lower feed rates allow for more gradual deformation, reducing stress concentrations but increasing production time.

- Spindle Speed: Influences frictional heating and material flow. Excessive speeds can induce thermal stresses, while low speeds may lead to uneven deformation.

- Roller Diameter: Larger rollers distribute forming forces over a wider area, reducing localized stress concentrations but potentially compromising precision for small-diameter cones.

- Forming Force: Directly correlates with stress magnitude. Optimal force balances deformation efficiency with material integrity, avoiding excessive thinning or fracture.

Tooling Design

The mandrel and roller geometries are critical to stress regulation. A mandrel with a smooth, tapered profile minimizes stress concentrations, while a poorly designed mandrel can induce localized buckling. Roller geometry, including nose radius and contact angle, affects the contact stress distribution. A smaller nose radius increases contact pressure, leading to higher stresses, whereas a larger radius promotes uniform deformation.

Boundary Conditions

Clamping conditions and frictional interactions between the blank, mandrel, and roller influence stress distribution. High friction at the mandrel-blank interface can restrict material flow, increasing tensile stresses, while low friction facilitates smoother deformation but may lead to slippage. Lubrication strategies, such as the use of molybdenum disulfide or oil-based lubricants, are employed to optimize frictional conditions.

Experimental and Simulation-Based Insights

Experimental studies and numerical simulations provide critical insights into stress distribution. Techniques like strain gauging, digital image correlation (DIC), and X-ray diffraction are used to measure stress and strain fields in spun components. For instance, DIC has been employed to map strain distributions in aluminum conical components, revealing peak strains at the smaller diameter end.

FEA simulations, using software like ABAQUS or ANSYS, model the triaxial stress state and predict stress concentrations. A notable study on shear spinning of AA6061 conical components used DEFORM-3D to simulate multi-pass spinning, demonstrating that stress peaks occur at the roller contact zone and diminish with subsequent passes. These simulations also highlight the role of residual stresses, which can be compressive in the inner surface and tensile in the outer surface, affecting component performance.

Regulation Mechanisms for Stress Distribution

Process Optimization Strategies

Regulating stress distribution requires optimizing process parameters to achieve uniform deformation and minimize defects. Key strategies include:

- Adaptive Feed Rate Control: CNC systems can dynamically adjust the roller feed rate based on real-time feedback from load sensors, reducing stress concentrations in high-deformation zones.

- Multi-Pass Spinning: Dividing the forming process into multiple passes allows for gradual deformation, distributing stresses more evenly. Each pass reduces the blank’s thickness incrementally, mitigating the risk of cracking.

- Variable Roller Path: Programming the roller to follow a non-linear path, such as a sinusoidal or spiral trajectory, can distribute deformation more uniformly, particularly for complex conical geometries.

- Thermal Management: Controlling frictional heating through lubrication and spindle speed optimization minimizes thermal stresses, which can exacerbate stress concentrations.

Tooling and Mandrel Design

Advanced tooling designs enhance stress regulation. For instance, segmented mandrels with adjustable cone angles allow for tailored deformation paths, reducing stress gradients. Rollers with variable nose radii, controlled via CNC, can adapt to different stages of deformation, applying higher pressure in initial passes and lighter pressure in finishing passes.

Material Pre-Processing

Pre-processing techniques, such as annealing or pre-forming, modify the blank’s microstructure to improve formability. Annealing reduces residual stresses and enhances ductility, allowing the material to withstand higher deformation without cracking. Pre-forming, such as initial bending of the blank, can distribute stresses more evenly during spinning.

Real-Time Monitoring and Control

Modern CNC spinning machines incorporate sensors for real-time monitoring of forming forces, strains, and temperatures. These data feed into adaptive control algorithms that adjust process parameters to maintain optimal stress distribution. For example, load sensors on the roller can detect excessive stress concentrations, triggering a reduction in feed rate or forming force.

Advanced Simulation Techniques

FEA-based optimization is a powerful tool for stress regulation. By simulating various process scenarios, engineers can identify parameter combinations that minimize stress concentrations. Recent advancements in machine learning have enabled predictive models that correlate process parameters with stress outcomes, further refining regulation strategies.

Comparative Analysis of Recent Research

To elucidate the state-of-the-art in stress regulation for CNC spinning of conical components, the following tables compare recent research findings. These studies, drawn from peer-reviewed literature, focus on material behavior, process parameters, and stress outcomes.

Table 1: Material Properties and Stress Distribution

| Study | Material | Yield Strength (MPa) | Strain Hardening Exponent (n) | Key Findings on Stress Distribution | Source |

|---|---|---|---|---|---|

| Li et al. (2020) | AA6061-T6 | 240 | 0.23 | Uniform stress distribution achieved with low feed rates; tensile stresses dominate at smaller diameter. | |

| Zhang et al. (2021) | Ti-6Al-4V | 880 | 0.15 | High stress concentrations due to limited ductility; multi-pass spinning reduces peak stresses by 20%. | |

| Wang et al. (2022) | 304 Stainless Steel | 310 | 0.28 | Compressive residual stresses on inner surface enhance fatigue life; high friction increases tensile stresses. | |

| Chen et al. (2023) | AA7075 | 470 | 0.20 | Anisotropy leads to non-uniform stress distribution; pre-annealing reduces stress gradients by 15%. | Journal of Materials Processing Technology |

Table 2: Process Parameters and Stress Outcomes

| Study | Feed Rate (mm/min) | Spindle Speed (rpm) | Roller Diameter (mm) | Stress Outcome | Source |

|---|---|---|---|---|---|

| Li et al. (2020) | 50–100 | 500–1000 | 20 | Lower feed rates reduce peak stresses by 10%; optimal spindle speed minimizes thermal stresses. | |

| Zhang et al. (2021) | 30–80 | 300–800 | 15 | High feed rates increase wrinkling risk; smaller roller diameter elevates contact stresses. | |

| Kim et al. (2022) | 40–120 | 600–1200 | 25 | Variable feed rate control reduces stress concentrations by 12% compared to constant feed. | International Journal of Machine Tools and Manufacture |

| Liu et al. (2023) | 60–150 | 400–1000 | 30 | Multi-pass spinning with increasing roller diameter distributes stresses evenly, reducing defects. | |

| Zhang et al. (2021) | Segmented | 3–7 | Adjustable cone angle | Allows tailored deformation, reducing stress gradients by 15%. | |

| Wang et al. (2022) | Fixed Conical | 10 | Polished surface | Minimizes frictional stresses, improving stress uniformity. | |

| Park et al. (2023) | Modular | 4–8 | Variable radius roller | Dynamic radius adjustment reduces peak contact stresses by 10%. | Journal of Manufacturing Processes |

Analysis of Comparative Data

The tables reveal several trends:

- Material Influence: High-strength materials like Ti-6Al-4V exhibit greater stress concentrations due to limited ductility, necessitating multi-pass strategies. Aluminum alloys, with moderate strain hardening, achieve more uniform stress distributions under optimized conditions.

- Process Parameter Optimization: Lower feed rates and adaptive control strategies consistently reduce peak stresses, while spindle speed must be balanced to avoid thermal effects. Larger roller diameters distribute forces more evenly, particularly in finishing passes.

- Tooling Innovations: Segmented mandrels and variable-radius rollers offer significant advantages in stress regulation, allowing for tailored deformation paths that mitigate stress gradients.

These findings underscore the importance of integrated approaches combining material selection, process optimization, and advanced tooling to regulate stress distribution effectively.

Applications and Industrial Relevance

Aerospace Applications

Conical components produced via CNC spinning are critical in aerospace, where lightweight, high-strength structures are essential. Rocket nozzles, for instance, require precise stress regulation to withstand extreme thermal and mechanical loads. Studies on Ti-6Al-4V conical nozzles demonstrate that multi-pass spinning with optimized feed rates reduces residual tensile stresses, enhancing fatigue life.

Automotive and Energy Sectors

In automotive applications, conical components like exhaust cones benefit from CNC spinning’s ability to produce thin-walled, durable parts. Stainless steel cones, spun with polished mandrels, exhibit compressive residual stresses that improve corrosion resistance. In the energy sector, pressure vessel heads and turbine components leverage CNC spinning for cost-effective production of complex geometries.

Emerging Trends

Recent advancements include the integration of machine learning for predictive stress modeling and the development of hybrid spinning processes combining CNC spinning with additive manufacturing. These innovations promise to further enhance stress regulation, enabling the production of next-generation conical components with unprecedented precision and performance.

Challenges and Future Directions

Current Challenges

Despite significant progress, challenges remain in regulating stress distribution:

- Material Variability: Variations in material properties, particularly in high-strength alloys, complicate stress prediction and control.

- Complex Geometries: Conical components with variable wall thicknesses or non-uniform tapers require advanced simulation and control strategies.

- Residual Stress Management: Balancing compressive and tensile residual stresses to optimize performance remains a key challenge.

- Scalability: Scaling CNC spinning for large-scale production without compromising stress regulation is a practical concern.

Future Research Directions

Future research should focus on:

- Advanced Simulation Models: Developing multi-physics models that integrate thermal, mechanical, and microstructural effects for more accurate stress predictions.

- Smart Manufacturing: Leveraging Industry 4.0 technologies, such as IoT and real-time data analytics, for dynamic stress regulation.

- Sustainable Materials: Exploring eco-friendly materials with favorable stress distribution characteristics to align with sustainability goals.

- Hybrid Processes: Investigating combinations of CNC spinning with other forming techniques to address complex stress distribution challenges.

Conclusion

The regulation of stress distribution in CNC spinning of conical components is a multifaceted challenge that integrates material science, mechanical engineering, and advanced manufacturing. By optimizing process parameters, tooling designs, and control strategies, manufacturers can achieve uniform stress distributions, minimize defects, and enhance component performance. Comparative analyses of recent research highlight the efficacy of multi-pass spinning, adaptive control, and innovative tooling in stress regulation. As industries demand increasingly complex and high-performance conical components, ongoing advancements in simulation, monitoring, and hybrid processes will drive the evolution of CNC spinning, ensuring its continued relevance in modern manufacturing.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,