Vacuum stainless steel insulation containers, often referred to as vacuum flasks or thermoses, are ubiquitous in modern life due to their exceptional ability to maintain the temperature of their contents over extended periods. The manufacturing process of these containers involves several intricate steps, with the spinning process being a critical component. This article delves into the spinning process of vacuum stainless steel insulation containers, providing a comprehensive and scientific overview.

Introduction to Vacuum Stainless Steel Insulation Containers

Vacuum stainless steel insulation containers are designed to keep beverages and food at a consistent temperature, whether hot or cold. The core principle behind their effectiveness is the vacuum insulation, which minimizes heat transfer by conduction and convection. The stainless steel construction ensures durability, corrosion resistance, and hygiene.

The manufacturing process of these containers involves several stages, including material selection, forming, welding, vacuum sealing, and finishing. Among these, the spinning process is pivotal in shaping the stainless steel into the desired form.

The Spinning Process

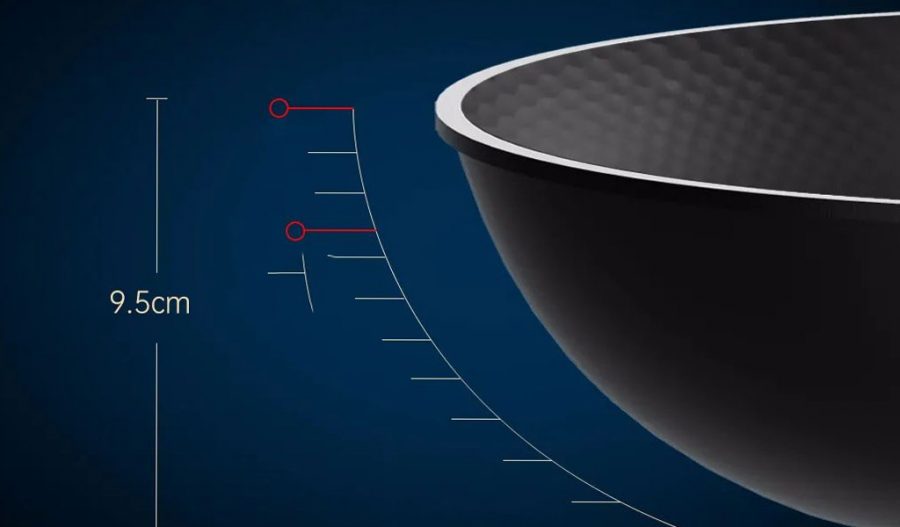

The spinning process, also known as metal spinning or spin forming, is a metalworking technique that involves rotating a metal disc or tube at high speeds while applying a forming tool to shape it into the desired form. This process is particularly suitable for creating axisymmetric parts, such as the cylindrical bodies of vacuum insulation containers.

Material Selection

The choice of material is crucial for the performance and longevity of vacuum insulation containers. Stainless steel, particularly grades 304 and 316, is commonly used due to its excellent corrosion resistance, strength, and thermal properties. These grades contain chromium and nickel, which enhance their resistance to oxidation and corrosion.

Preparation of the Blank

The spinning process begins with the preparation of a metal blank, which is a flat disc or a pre-formed tube of stainless steel. The dimensions of the blank are carefully calculated to ensure that it can be spun into the desired shape without excessive material waste.

Mounting and Rotation

The blank is mounted onto a spinning lathe, which rotates it at high speeds. The rotation speed is typically between 500 and 2000 revolutions per minute (RPM), depending on the size and thickness of the blank. The high-speed rotation ensures uniform deformation and prevents the formation of defects.

Forming Tools

Forming tools, often made of hardened steel or carbide, are used to shape the rotating blank. These tools apply pressure to the blank, gradually deforming it into the desired shape. The tools are guided by a template or a mandrel, which ensures consistency in the final product.

Annealing

During the spinning process, the stainless steel may undergo work hardening, which increases its strength but reduces its ductility. To restore ductility and prevent cracking, the material may be annealed. Annealing involves heating the stainless steel to a specific temperature and then allowing it to cool slowly, which relieves internal stresses and softens the material.

Quality Control

Throughout the spinning process, quality control measures are implemented to ensure the integrity and uniformity of the spun parts. Dimensional accuracy, surface finish, and material properties are closely monitored. Non-destructive testing methods, such as ultrasonic testing and radiographic inspection, may be used to detect any defects.

Comparison of Spinning Techniques

The spinning process can be categorized into several techniques, each with its own advantages and limitations. The following table compares the most common spinning techniques used in the manufacture of vacuum stainless steel insulation containers:

| Spinning Technique | Description | Advantages | Limitations |

|---|---|---|---|

| Conventional Spinning | Uses a single forming tool to shape the blank. | Simple setup, cost-effective, suitable for small to medium production runs. | Limited to simple shapes, slower production rate. |

| Shear Spinning | Involves shearing the material to reduce thickness and increase diameter. | Can produce complex shapes, reduces material thickness. | Requires specialized equipment, higher tooling costs. |

| Flow Forming | Uses a combination of spinning and rolling to shape the material. | Can produce intricate shapes, high dimensional accuracy. | Complex setup, higher production costs. |

| Hot Spinning | Involves heating the material before spinning. | Suitable for hard-to-form materials, reduces work hardening. | Requires heating equipment, longer cycle times. |

Advantages of the Spinning Process

The spinning process offers several advantages in the manufacture of vacuum stainless steel insulation containers:

- Cost-Effectiveness: The spinning process is generally more cost-effective than other forming methods, such as deep drawing or hydroforming, especially for small to medium production runs.

- Versatility: Spinning can produce a wide range of shapes and sizes, making it suitable for various container designs.

- High Precision: The spinning process allows for high dimensional accuracy and consistent wall thickness, which are critical for the performance of vacuum insulation containers.

- Material Efficiency: Spinning minimizes material waste, as the blank is gradually deformed into the final shape without significant trimming or cutting.

- Surface Finish: The spinning process can achieve a smooth and uniform surface finish, which is essential for the aesthetic and functional qualities of the containers.

Challenges and Limitations

Despite its advantages, the spinning process also presents certain challenges and limitations:

- Tooling Costs: The initial cost of tooling can be high, especially for complex shapes that require specialized forming tools.

- Production Rate: The spinning process may have a slower production rate compared to other mass-production methods, such as stamping or injection molding.

- Material Limitations: Certain materials, particularly those with high hardness or low ductility, may be difficult to spin without annealing or additional processing steps.

- Equipment Requirements: The spinning process requires specialized equipment, including spinning lathes and forming tools, which can be costly to acquire and maintain.

Innovations in the Spinning Process

Recent advancements in technology have led to innovations in the spinning process, enhancing its efficiency and capabilities:

- CNC Spinning: Computer Numerical Control (CNC) spinning machines allow for precise control over the spinning process, enabling the production of complex shapes with high accuracy.

- Laser-Assisted Spinning: Laser-assisted spinning uses laser heating to soften the material during the spinning process, reducing work hardening and improving formability.

- Hybrid Spinning: Hybrid spinning combines spinning with other forming techniques, such as hydroforming or incremental forming, to produce intricate shapes and improve material properties.

- Automated Quality Control: Automated quality control systems use sensors and machine learning algorithms to monitor the spinning process in real-time, detecting and correcting defects to ensure consistent quality.

Environmental Considerations

The manufacturing of vacuum stainless steel insulation containers has environmental implications, and the spinning process is no exception. Efforts are being made to minimize the environmental impact through sustainable practices:

- Material Recycling: Stainless steel is highly recyclable, and efforts are made to recycle scrap material generated during the spinning process.

- Energy Efficiency: Modern spinning machines are designed to be energy-efficient, reducing the carbon footprint of the manufacturing process.

- Waste Reduction: The spinning process inherently minimizes material waste, and additional measures, such as optimizing blank dimensions, further reduce waste.

- Emission Control: Proper ventilation and emission control systems are employed to minimize the release of harmful fumes and particles during the spinning process.

Case Studies

To illustrate the practical application of the spinning process in the manufacture of vacuum stainless steel insulation containers, several case studies are presented:

Case Study 1: Production of High-End Thermoses

A leading manufacturer of high-end thermoses employed the spinning process to produce containers with superior insulation properties. The containers were spun from 304 stainless steel blanks, with a wall thickness of 1.5 mm. The spinning process involved multiple passes with forming tools to achieve the desired shape and dimensional accuracy. The containers were then vacuum-sealed and finished with a polished surface. The resulting thermoses demonstrated excellent temperature retention and durability, meeting the high standards of the premium market.

Case Study 2: Mass Production of Insulated Bottles

A company specializing in mass-produced insulated bottles utilized the spinning process to manufacture containers for the consumer market. The containers were spun from 316 stainless steel blanks, with a wall thickness of 1.2 mm. The spinning process was automated using CNC spinning machines, which ensured consistent quality and high production rates. The containers were then vacuum-sealed and finished with a powder-coated surface for enhanced durability and aesthetic appeal. The insulated bottles were widely distributed and received positive feedback for their performance and affordability.

Case Study 3: Custom Insulation Containers for Industrial Applications

An industrial equipment manufacturer required custom insulation containers for transporting temperature-sensitive materials. The containers were spun from high-strength stainless steel blanks, with a wall thickness of 2.0 mm. The spinning process involved shear spinning to reduce the material thickness and increase the diameter, followed by flow forming to achieve the final shape. The containers were then vacuum-sealed and finished with a corrosion-resistant coating. The custom insulation containers met the stringent requirements of the industrial application, ensuring reliable temperature control and durability.

Conclusion

The spinning process plays a crucial role in the manufacture of vacuum stainless steel insulation containers, enabling the production of high-quality, durable, and efficient products. Through careful material selection, precise forming techniques, and rigorous quality control, the spinning process ensures the superior performance of these containers. Continuous innovations and sustainable practices further enhance the efficiency and environmental friendliness of the spinning process, making it a cornerstone of modern manufacturing.

As the demand for vacuum stainless steel insulation containers continues to grow, driven by the increasing need for energy-efficient and sustainable solutions, the spinning process will remain an essential component of their production. Future advancements in technology and materials science are expected to further optimize the spinning process, leading to even more efficient and high-performance containers.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,