CNC (Computer Numerical Control) spinning, also known as metal spinning, is a metalworking process where a sheet or tube of metal is rotated at high speed and formed into a symmetrical part by pressing against a spinning mandrel. This process, traditionally performed manually by skilled artisans, has evolved significantly with the advent of CNC technology, enabling automated, precise, and repeatable production.

CNC spinning software plays a critical role in this evolution by providing the necessary tools for designing, simulating, and controlling the spinning process. These software solutions enable manufacturers to create complex shapes with high accuracy, reduce material waste, and increase production speed, making CNC spinning an integral part of various industries, including aerospace, automotive, and consumer products.The success of CNC spinning relies heavily on sophisticated software that can translate intricate designs into machine-readable instructions. This article provides an overview of the top 10 CNC spinning software programs available in the market.

1. SolidWorks

SolidWorks is a popular CAD (Computer-Aided Design) software that is widely used in various industries, including CNC spinning. Developed by Dassault Systèmes, SolidWorks provides robust modeling capabilities that allow users to create detailed designs that can be directly translated into CNC machining instructions. The software’s seamless integration with CAM (Computer-Aided Manufacturing) tools, such as SolidCAM, enhances its utility in CNC spinning by enabling the precise control of tool paths and machine operations.

SolidWorks is known for its user-friendly interface, comprehensive simulation tools, and extensive library of materials and components, which make it a preferred choice for both novice and experienced engineers. The software also supports parametric design, which allows for easy modifications and optimization of spinning processes.

2. Siemens NX

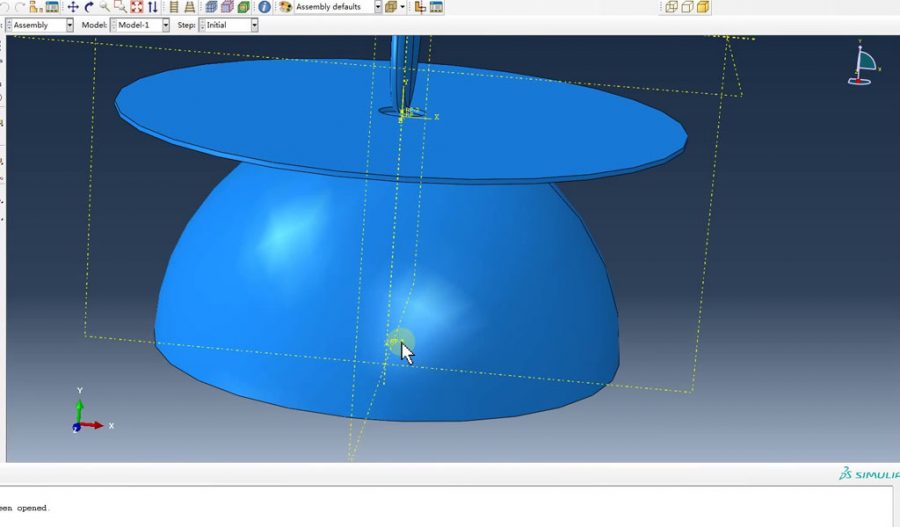

Siemens NX is a high-end CAD/CAM/CAE software suite developed by Siemens Digital Industries Software. Renowned for its advanced capabilities, Siemens NX is widely used in industries that demand precision and complexity, such as aerospace and automotive manufacturing. The software offers powerful CNC programming tools that support multi-axis machining, making it ideal for CNC spinning operations.

Siemens NX provides comprehensive simulation features that allow engineers to visualize the spinning process, predict potential issues, and optimize tool paths for maximum efficiency. The software also includes a wide range of post-processing tools that enable seamless communication with CNC machines, ensuring that the designs are accurately translated into physical components.

3. Mastercam

Mastercam is one of the most widely used CAM software programs in the CNC machining industry. Developed by CNC Software, Inc., Mastercam offers a range of solutions tailored to different manufacturing needs, including CNC spinning. The software provides an intuitive interface, making it accessible to both beginners and experienced users.

Mastercam’s strengths lie in its powerful toolpath generation capabilities, which allow users to create efficient and precise machining instructions for CNC spinning. The software also offers advanced simulation features, enabling users to test and optimize their designs before actual production. Mastercam supports a variety of machine types and configurations, making it a versatile tool in the CNC spinning industry.

4. Esprit

Esprit is a high-performance CAM software developed by DP Technology Corp. It is known for its versatility and ability to handle complex machining tasks, including CNC spinning. Esprit offers a comprehensive suite of tools for programming, simulation, and optimization, making it a preferred choice for manufacturers looking to enhance their CNC spinning operations.

One of the key features of Esprit is its ability to generate highly efficient toolpaths, which reduce machining time and material waste. The software also provides detailed simulations that allow users to visualize the spinning process, identify potential issues, and make necessary adjustments before production begins. Esprit’s post-processing capabilities ensure smooth communication with CNC machines, leading to accurate and reliable results.

5. Fusion 360

Fusion 360, developed by Autodesk, is a cloud-based CAD/CAM/CAE software that has gained popularity due to its accessibility and comprehensive features. Fusion 360 is particularly well-suited for small to medium-sized enterprises that require an affordable yet powerful solution for CNC spinning and other machining processes.

Fusion 360 offers an integrated platform for design, engineering, and manufacturing, allowing users to create detailed models, generate toolpaths, and simulate the spinning process within a single environment. The software’s cloud-based nature enables collaboration across teams and locations, making it an ideal choice for companies with distributed operations. Fusion 360’s affordability and ease of use make it a popular choice for startups and individual engineers involved in CNC spinning.

6. SolidCAM

SolidCAM is a powerful CAM software that integrates seamlessly with SolidWorks, providing a comprehensive solution for CNC machining, including spinning. Developed by SolidCAM Ltd., the software offers advanced toolpath generation and simulation features that are essential for precise and efficient CNC spinning operations.

SolidCAM’s iMachining technology is one of its standout features, providing highly optimized toolpaths that significantly reduce machining time while extending tool life. The software also offers a wide range of post-processing options, ensuring compatibility with various CNC machines and controllers. SolidCAM’s deep integration with SolidWorks makes it a natural choice for users who are already familiar with the SolidWorks environment.

7. Edgecam

Edgecam is a CAM software developed by Hexagon Manufacturing Intelligence that is widely used in the CNC machining industry, including for spinning applications. Edgecam is known for its intuitive interface, making it accessible to users of all skill levels. The software offers a range of machining strategies, including turning, milling, and multi-axis machining, which are essential for CNC spinning.

Edgecam’s simulation tools allow users to visualize the spinning process in detail, enabling them to identify potential issues and optimize toolpaths before production begins. The software also supports a wide range of machine configurations, making it a versatile choice for manufacturers with diverse CNC spinning needs.

8. GibbsCAM

GibbsCAM, developed by 3D Systems, is a powerful CAM software that is widely used in the CNC machining industry. GibbsCAM offers a range of features tailored to different machining processes, including CNC spinning. The software is known for its user-friendly interface and powerful toolpath generation capabilities.

GibbsCAM’s ability to handle complex multi-axis machining makes it well-suited for CNC spinning operations that require precision and efficiency. The software also offers advanced simulation tools that allow users to test and optimize their designs before production, reducing the risk of errors and material waste. GibbsCAM’s versatility and ease of use make it a popular choice among CNC machinists.

9. HyperMILL

HyperMILL, developed by Open Mind Technologies, is a high-performance CAM software that is widely used in the aerospace, automotive, and medical industries. HyperMILL offers a comprehensive suite of tools for CNC programming, including those tailored for CNC spinning. The software is known for its advanced machining strategies and optimization features.

HyperMILL’s key strength lies in its ability to generate efficient and precise toolpaths, reducing machining time and improving the quality of the final product. The software also offers detailed simulations that allow users to visualize the spinning process and make necessary adjustments before production. HyperMILL’s advanced features make it a preferred choice for manufacturers with demanding CNC spinning requirements.

10. Tebis

Tebis is a CAD/CAM software suite developed by Tebis AG that is known for its high-quality machining capabilities. Tebis offers a range of solutions tailored to different manufacturing processes, including CNC spinning. The software is widely used in industries that require precision and complexity, such as aerospace and automotive manufacturing.

Tebis offers advanced toolpath generation and simulation features, allowing users to optimize their CNC spinning operations for maximum efficiency and accuracy. The software’s intuitive interface and comprehensive support for multi-axis machining make it a versatile tool for manufacturers with diverse CNC spinning needs. Tebis also offers extensive post-processing options, ensuring compatibility with a wide range of CNC machines.

Conclusion

The CNC spinning industry relies heavily on advanced software to translate complex designs into precise and efficient machining instructions. The ten software programs highlighted in this article—SolidWorks, Siemens NX, Mastercam, Esprit, Fusion 360, SolidCAM, Edgecam, GibbsCAM, HyperMILL, and Tebis—represent the leading solutions available in the market today. Each of these programs offers unique features and capabilities, making them suitable for different applications and industries. As the demand for precision and efficiency in manufacturing continues to grow, these software programs will play a crucial role in advancing CNC spinning technology.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,