Metal spinning and laser-assisted forming represent two advanced manufacturing techniques that have gained significant attention in modern industrial applications. Metal spinning, a chipless forming process, involves rotating a metal blank or preform while applying localized pressure to shape it into axisymmetric components, such as cones, cylinders, or hemispheres. Laser-assisted forming, on the other hand, leverages the precise application of laser-induced thermal energy to enhance material formability, reduce forming forces, and mitigate defects. When combined, these processes create a synergistic mechanism that enhances the capabilities of each, enabling the production of complex, high-performance components from challenging materials like titanium, high-strength steels, and nickel-based alloys. This article explores the synergistic mechanisms of metal spinning and laser-assisted forming, delving into their principles, interactions, applications, and recent advancements. Detailed comparisons of process parameters, material responses, and outcomes are provided to elucidate their combined potential.

Fundamentals of Metal Spinning

Historical Context and Evolution

Metal spinning, also known as spin forming or spinning, traces its origins to ancient civilizations, where manual techniques were used to shape metals into functional objects. The industrial revolution marked a turning point, with mechanized spinning processes emerging in the 19th century. Today, computer numerical control (CNC) systems have revolutionized metal spinning, enabling precise control over tool paths and forming parameters. The process is widely used in industries such as aerospace, automotive, and energy for producing lightweight, high-strength components.

Process Mechanics

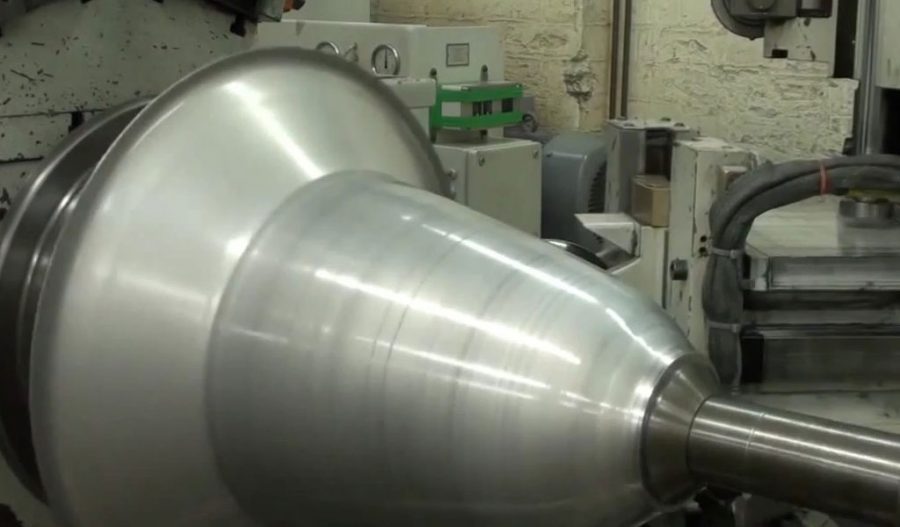

Metal spinning involves clamping a metal blank—typically a flat disk or a preformed shape—onto a rotating mandrel. A forming tool, often a roller, applies localized pressure to deform the blank incrementally, shaping it against the mandrel’s contour. The process can be categorized into conventional spinning, shear spinning, and flow forming, each distinguished by the degree of thickness reduction and deformation mechanics.

- Conventional Spinning: Maintains the blank’s original thickness while shaping it into the desired geometry. It is ideal for producing shallow, axisymmetric parts like bowls or lamp reflectors.

- Shear Spinning: Reduces the blank’s thickness by applying shear forces, resulting in conical or tapered components with enhanced strength-to-weight ratios.

- Flow Forming: Extends shear spinning by significantly reducing thickness and elongating the workpiece, often used for tubular components like rocket casings.

The mechanics of metal spinning rely on plastic deformation, where the material undergoes localized yielding under compressive and tensile stresses. The process is inherently incremental, allowing for precise control over strain distribution and minimizing the risk of defects like wrinkling or cracking.

Material Considerations

Metal spinning is versatile, accommodating a wide range of materials, including aluminum, stainless steel, copper, and titanium. The choice of material influences process parameters such as rotational speed, tool force, and feed rate. Ductile materials like aluminum are easier to spin, while high-strength alloys require elevated temperatures or specialized tooling to enhance formability. The material’s microstructure, grain size, and work-hardening behavior also play critical roles in determining the quality of the spun part.

Advantages and Limitations

Metal spinning offers several advantages, including low tooling costs, flexibility in part design, and the ability to produce seamless components with excellent surface finishes. However, it is limited to axisymmetric geometries and may require multiple passes to achieve complex shapes. High-strength materials pose challenges due to their limited formability at room temperature, often necessitating auxiliary heating methods.

Principles of Laser-Assisted Forming

Overview of Laser Technology in Manufacturing

Laser-assisted forming utilizes a focused laser beam to deliver controlled thermal energy to a workpiece, inducing localized heating that enhances material ductility and reduces flow stress. The process emerged in the late 20th century with advancements in laser technology, particularly in high-power CO2 and fiber lasers. Lasers offer unparalleled precision, enabling selective heating of specific regions without affecting the surrounding material. In forming applications, laser-assisted techniques are used to bend, stretch, or shape metals that are difficult to deform under conventional conditions.

Mechanisms of Laser-Induced Heating

The interaction between a laser beam and a metal surface involves absorption, reflection, and conduction of thermal energy. When a laser irradiates a workpiece, a portion of the energy is absorbed, raising the surface temperature. The heat conducts into the material, creating a temperature gradient that influences the mechanical properties. Key mechanisms include:

- Thermal Softening: Elevated temperatures reduce the material’s yield strength and flow stress, enhancing ductility and formability.

- Phase Transformations: In some alloys, laser heating induces microstructural changes, such as recrystallization or phase transitions, which can improve formability or mechanical properties.

- Stress Relaxation: Localized heating mitigates residual stresses, reducing the risk of cracking or springback.

The effectiveness of laser-assisted forming depends on parameters such as laser power, beam diameter, scanning speed, and material absorptivity. These factors must be optimized to achieve the desired temperature field without causing melting or thermal damage.

Types of Laser-Assisted Forming Processes

Laser-assisted forming encompasses several techniques, each tailored to specific applications:

- Laser-Assisted Bending: A laser beam heats a localized region of a sheet or plate, inducing thermal stresses that cause bending. This is effective for precise angle control in high-strength materials.

- Laser-Assisted Incremental Forming: Combines laser heating with incremental deformation, enabling the forming of complex, non-axisymmetric shapes.

- Laser-Assisted Spinning: Integrates laser heating into the spinning process, enhancing the formability of challenging materials by selectively heating the deformation zone.

Advantages and Challenges

Laser-assisted forming offers significant advantages, including improved formability, reduced forming forces, and the ability to process high-strength or brittle materials. It also enables precise control over thermal and mechanical interactions, minimizing defects. However, challenges include high equipment costs, the need for precise control to avoid overheating, and potential microstructural alterations that may affect the part’s performance.

Synergistic Integration of Metal Spinning and Laser-Assisted Forming

Rationale for Integration

The integration of metal spinning and laser-assisted forming addresses the limitations of each process while amplifying their strengths. Metal spinning excels in producing axisymmetric components but struggles with high-strength materials due to their limited ductility at room temperature. Laser-assisted forming overcomes this by providing localized heating, which softens the material and enhances its formability. The synergy lies in combining the incremental, controlled deformation of spinning with the thermal enhancement of laser heating, enabling the production of complex components from challenging materials with improved efficiency and quality.

Synergistic Mechanisms

The synergistic mechanism of metal spinning and laser-assisted forming can be understood through the interplay of thermal, mechanical, and microstructural effects:

- Thermal Enhancement of Formability:

- The laser beam selectively heats the deformation zone, reducing the material’s yield strength and flow stress. This allows the spinning tool to deform the material with lower forces, minimizing tool wear and energy consumption.

- Controlled heating ensures that only the forming zone is softened, preserving the structural integrity of the surrounding material.

- Reduction of Forming Defects:

- Laser heating mitigates common spinning defects such as wrinkling, cracking, and thinning by improving material ductility and reducing strain localization.

- The thermal gradient induced by the laser can be tailored to promote uniform deformation, enhancing dimensional accuracy.

- Microstructural Control:

- Laser-assisted spinning enables precise control over the material’s microstructure by inducing localized recrystallization or phase transformations. This can enhance the mechanical properties of the spun part, such as strength, ductility, or fatigue resistance.

- Rapid heating and cooling cycles minimize undesirable microstructural changes, such as grain coarsening or embrittlement.

- Process Efficiency:

- The combination of laser heating and spinning reduces the number of forming passes required, as the material can be deformed more readily in a single pass.

- Lower forming forces and improved material flow reduce energy consumption and cycle times, enhancing overall process efficiency.

Process Configuration

In a typical laser-assisted metal spinning setup, a CNC spinning machine is equipped with a laser source, such as a fiber or CO2 laser, integrated into the forming head or positioned externally. The laser beam is directed at the deformation zone, either continuously or in pulses, to maintain the desired temperature field. Key components include:

- Laser Delivery System: Includes optics to focus and direct the beam, ensuring precise heating of the forming zone.

- Temperature Monitoring: Infrared cameras or pyrometers monitor the workpiece temperature in real-time, enabling closed-loop control of laser power.

- CNC Control System: Synchronizes the spinning tool’s motion with the laser’s scanning path, ensuring optimal alignment of thermal and mechanical inputs.

- Cooling System: Prevents overheating of the tool or workpiece, maintaining process stability.

The laser can be applied in various configurations, such as stationary heating, scanning along the tool path, or dynamic adjustment based on the deformation stage. The choice of configuration depends on the material, geometry, and desired outcomes.

Material-Specific Synergistic Effects

Titanium Alloys

Titanium alloys, such as Ti-6Al-4V, are widely used in aerospace and medical applications due to their high strength-to-weight ratio and corrosion resistance. However, their low ductility at room temperature makes them challenging to spin. Laser-assisted spinning addresses this by heating the deformation zone to 600–800°C, significantly improving formability. The synergistic effects include:

- Enhanced Ductility: Laser heating reduces flow stress, allowing titanium to be spun into complex shapes without cracking.

- Microstructural Stability: Controlled heating minimizes alpha-case formation and grain coarsening, preserving the alloy’s mechanical properties.

- Reduced Tool Wear: Lower forming forces decrease wear on the spinning tool, extending its lifespan.

Table 1: Comparison of Titanium Alloy Spinning with and without Laser Assistance

| Parameter | Conventional Spinning | Laser-Assisted Spinning |

|---|---|---|

| Forming Temperature (°C) | 20–200 | 600–800 |

| Maximum Strain (%) | 10–15 | 30–40 |

| Forming Force (kN) | 50–100 | 20–50 |

| Surface Defects | Cracking, Wrinkling | Minimal |

| Tool Wear Rate | High | Low |

| Cycle Time (min) | 10–15 | 5–8 |

High-Strength Steels

Advanced high-strength steels (AHSS), such as DP-800, are critical in automotive applications for their strength and lightweight properties. Their high yield strength limits formability in conventional spinning, often leading to springback or cracking. Laser-assisted spinning mitigates these issues by heating the material to 400–600°C, reducing flow stress and enabling precise forming. Key benefits include:

- Springback Reduction: Thermal softening minimizes residual stresses, improving dimensional accuracy.

- Improved Surface Quality: Laser heating reduces friction and surface defects, enhancing the part’s finish.

- Energy Efficiency: Lower forming forces and fewer passes reduce energy consumption.

Table 2: Comparison of AHSS Spinning with and without Laser Assistance

| Parameter | Conventional Spinning | Laser-Assisted Spinning |

|---|---|---|

| Forming Temperature (°C) | 20–150 | 400–600 |

| Springback Angle (°) | 5–10 | 1–3 |

| Forming Force (kN) | 80–120 | 40–70 |

| Surface Roughness (µm) | 2–4 | 1–2 |

| Cycle Time (min) | 12–18 | 6–10 |

| Defect Rate (%) | 10–15 | 2–5 |

Nickel-Based Alloys

Nickel-based alloys, such as Inconel 718, are used in high-temperature applications like turbine blades. Their poor formability and high work-hardening rates make conventional spinning challenging. Laser-assisted spinning at 800–1000°C enhances ductility and reduces forming forces, enabling the production of complex geometries. Synergistic effects include:

- Formability Improvement: Laser heating allows for higher strains without fracture.

- Microstructural Enhancement: Controlled heating promotes dynamic recrystallization, improving fatigue resistance.

- Process Flexibility: Laser assistance enables multi-pass spinning of intricate shapes.

Table 3: Comparison of Nickel-Based Alloy Spinning with and without Laser Assistance

| Parameter | Conventional Spinning | Laser-Assisted Spinning |

|---|---|---|

| Forming Temperature (°C) | 20–300 | 800–1000 |

| Maximum Strain (%) | 5–10 | 20–30 |

| Forming Force (kN) | 100–150 | 50–80 |

| Microstructural Changes | Work Hardening | Dynamic Recrystallization |

| Cycle Time (min) | 15–20 | 8–12 |

| Defect Rate (%) | 15–20 | 5–8 |

Process Optimization and Control

Parameter Optimization

Optimizing the synergistic process requires balancing laser and spinning parameters to achieve the desired outcomes. Key parameters include:

- Laser Power (W): Determines the heating intensity and temperature field. Typical values range from 500–2000 W, depending on the material and thickness.

- Laser Scanning Speed (mm/s): Influences the heat input and thermal gradient. Faster speeds reduce overheating but may limit formability.

- Spinning Tool Force (kN): Affects deformation rate and strain distribution. Lower forces are required in laser-assisted spinning due to thermal softening.

- Rotational Speed (RPM): Controls the workpiece’s angular velocity, impacting heat dissipation and deformation dynamics.

- Feed Rate (mm/min): Determines the tool’s linear advancement, affecting the incremental deformation rate.

Optimization techniques, such as design of experiments (DOE) and finite element modeling (FEM), are used to identify optimal parameter combinations. For example, DOE can quantify the interaction between laser power and tool force, while FEM simulates thermal and mechanical responses to predict defects.

Real-Time Monitoring and Control

Real-time monitoring is critical for maintaining process stability and quality. Sensors, such as infrared cameras, pyrometers, and force-torque transducers, provide data on temperature, deformation forces, and tool wear. Advanced control systems use this data to adjust laser power, scanning speed, or tool force dynamically, ensuring consistent performance. Machine learning algorithms are increasingly employed to predict and mitigate defects, enhancing process robustness.

Table 4: Key Process Parameters and Their Effects

| Parameter | Range | Effect on Process |

|---|---|---|

| Laser Power (W) | 500–2000 | Increases temperature, reduces flow stress |

| Scanning Speed (mm/s) | 10–100 | Controls heat input, affects thermal gradient |

| Tool Force (kN) | 20–100 | Influences deformation rate, strain distribution |

| Rotational Speed (RPM) | 100–1000 | Affects heat dissipation, deformation dynamics |

| Feed Rate (mm/min) | 50–500 | Determines incremental deformation rate |

Applications in Industry

Aerospace

The aerospace industry benefits significantly from laser-assisted metal spinning, particularly for producing lightweight, high-strength components like engine casings, nose cones, and satellite dishes. Titanium and nickel-based alloys, which are prevalent in aerospace, are ideally suited for this process due to their enhanced formability under laser heating. The ability to produce seamless, axisymmetric parts with minimal defects reduces material waste and assembly costs.

Automotive

In the automotive sector, laser-assisted spinning is used to manufacture components like wheel rims, exhaust cones, and structural reinforcements from AHSS and aluminum alloys. The process’s ability to reduce springback and improve surface quality enhances part performance and aesthetics. Additionally, the energy efficiency of the synergistic process aligns with the industry’s sustainability goals.

Energy and Power Generation

The energy sector employs laser-assisted spinning for producing components like turbine blades, pressure vessels, and heat exchanger tubes. Nickel-based alloys and stainless steels, which are common in these applications, benefit from the improved formability and microstructural control offered by the synergistic process. The ability to produce thin-walled, high-strength components enhances system efficiency and reliability.

Medical Devices

In the medical field, laser-assisted spinning is used to fabricate implants, surgical instruments, and diagnostic equipment from titanium and stainless steel. The process’s precision and ability to minimize defects ensure compliance with stringent regulatory standards. The enhanced formability of biocompatible materials enables the production of complex, patient-specific geometries.

Recent Advances and Research Trends

Multi-Pass Laser-Assisted Spinning

Recent research has focused on multi-pass laser-assisted spinning, where the laser and spinning tool operate in multiple stages to achieve complex geometries. This approach allows for greater control over strain distribution and thermal history, reducing defects and improving mechanical properties. Studies have demonstrated its effectiveness in forming titanium and AHSS components with high dimensional accuracy.

Machine Learning Integration

Machine learning is transforming laser-assisted spinning by enabling predictive modeling and real-time process optimization. Algorithms trained on experimental data can predict defect formation, optimize parameter settings, and adapt to material variations. This enhances process reliability and reduces development time, particularly for new materials or geometries.

Hybrid Process Development

The integration of laser-assisted spinning with other processes, such as additive manufacturing or electrochemical machining, is an emerging trend. Hybrid processes combine the strengths of multiple techniques to achieve unprecedented levels of precision and performance. For example, laser-assisted spinning can be paired with selective laser melting to produce functionally graded components with tailored properties.

Sustainability and Energy Efficiency

Sustainability is a growing focus in manufacturing, and laser-assisted spinning contributes by reducing energy consumption and material waste. The process’s efficiency, coupled with its ability to recycle scrap material, aligns with circular economy principles. Research is ongoing to further minimize the environmental impact through advanced laser sources and process optimization.

Challenges and Future Directions

Technical Challenges

Despite its advantages, laser-assisted spinning faces several challenges:

- Thermal Management: Precise control of the temperature field is critical to avoid overheating or thermal damage. Advanced cooling systems and real-time monitoring are needed to address this.

- Equipment Costs: High-power lasers and integrated CNC systems are expensive, limiting adoption in small-scale industries.

- Material Variability: Variations in material properties, such as absorptivity or microstructure, can affect process consistency, requiring adaptive control strategies.

- Process Complexity: The integration of laser and spinning systems increases process complexity, necessitating skilled operators and robust control systems.

Future Directions

Future research and development in laser-assisted spinning are likely to focus on:

- Advanced Laser Sources: The adoption of ultrafast lasers, such as femtosecond or picosecond lasers, could enhance precision and minimize thermal damage.

- Smart Manufacturing: The integration of Industry 4.0 technologies, such as IoT and digital twins, will enable real-time process monitoring and optimization, improving efficiency and quality.

- Material Innovation: The development of new alloys and composites tailored for laser-assisted spinning will expand its applications, particularly in emerging fields like flexible electronics.

- Scalability: Efforts to scale the process for large-scale production, such as through multi-laser systems or automated setups, will enhance its industrial viability.

Conclusion

The synergistic mechanism of metal spinning and laser-assisted forming represents a transformative approach to advanced manufacturing. By combining the incremental deformation of spinning with the thermal enhancement of laser heating, this process enables the production of complex, high-performance components from challenging materials. The interplay of thermal, mechanical, and microstructural effects drives its effectiveness, offering benefits such as improved formability, reduced defects, and enhanced efficiency. Applications span aerospace, automotive, energy, and medical industries, with ongoing research pushing the boundaries of precision, sustainability, and scalability. As challenges like thermal management and equipment costs are addressed, laser-assisted spinning is poised to become a cornerstone of smart manufacturing, delivering innovative solutions for the demands of modern industry.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,