Welding is a critical fabrication process used to join metals or thermoplastics by applying heat, pressure, or both, resulting in a strong, permanent bond. The quality of a weld directly impacts the structural integrity, safety, and longevity of the welded component. Identifying a good weld requires a systematic evaluation of multiple factors, including visual characteristics, mechanical properties, and compliance with industry standards. This article provides a comprehensive, scientifically structured checklist for assessing weld quality, encompassing visual inspection, non-destructive testing (NDT), destructive testing, and adherence to codes and standards. Designed for welders, inspectors, engineers, and quality control professionals, this guide includes detailed explanations, comparative tables, and references to authoritative standards such as those from the American Welding Society (AWS), International Organization Read more

Matured Spinning Forming Technology for High-Performance Materials

Spinning forming technology, encompassing conventional spinning, shear spinning, and flow forming, represents a cornerstone of modern metalworking, particularly for the production of axisymmetric components. Over the past few decades, these techniques have matured significantly, driven by advancements in automation, material science, and computational modeling. Their application to high-performance materials—such as titanium alloys, aluminum alloys, magnesium alloys, nickel-based superalloys, and advanced composites—has expanded their relevance across industries like aerospace, automotive, defense, and energy. These materials, characterized by high strength-to-weight ratios, corrosion resistance, and thermal stability, pose unique challenges due to their complex deformation behaviors and limited formability at ambient temperatures. This article provides a comprehensive exploration of matured spinning forming technologies, their application to high-performance materials, and recent advancements, supported by Read more

Robotic metal spinning is an advanced manufacturing process that integrates robotic systems with the traditional technique of metal spinning, a form of plastic deformation used to produce axially symmetric or non-axisymmetric metal components. Metal spinning, also known as spin forming or spinning, involves rotating a metal blank (typically a disc or tube) at high speed while applying localized pressure with a tool—historically a manual spoon or roller—to shape the material over a mandrel. The incorporation of robotics into this process enhances precision, repeatability, and flexibility, allowing for the production of complex geometries that were once limited by the skill of human artisans. This article explores the principles, history, technological advancements, applications, and scientific underpinnings of robotic metal spinning, with a Read more

Metal spinning, also known as spin forming or spinning, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. This technique, which dates back centuries, has evolved significantly with advancements in technology and materials science, making it a critical method in modern bulk handling applications. In the context of bulk handling, metal spinning is employed to fabricate components such as containers, hoppers, silos, and chutes that are integral to industries like agriculture, mining, pharmaceuticals, and food processing. This article delves into the principles, processes, materials, applications, and scientific underpinnings of metal spinning as it pertains to bulk handling, providing a comprehensive exploration of its relevance in Read more

The Design and Implementation of HAVC System

Heating, Ventilation, and Air Conditioning (HVAC) systems are integral to modern building infrastructure, providing thermal comfort and maintaining indoor air quality (IAQ) across residential, commercial, and industrial environments. These systems regulate temperature, humidity, and air purity, ensuring occupant well-being and operational efficiency. The design and implementation of HVAC systems represent a multidisciplinary effort, combining principles of mechanical engineering, thermodynamics, fluid mechanics, and building science. Since their inception in the early 20th century, HVAC technologies have evolved significantly, driven by advancements in energy efficiency, environmental concerns, and the need for sustainable building practices. The term “HVAC” encompasses three primary functions: heating, which increases ambient temperature; ventilation, which circulates and refreshes air; and air conditioning, which cools and dehumidifies indoor spaces. In Read more

Galvanized Steel VS Stainless Steel

Galvanized steel and stainless steel are two widely utilized materials in construction, manufacturing, and various industrial applications, each prized for its unique properties and resistance to corrosion. These materials, while sharing some similarities as steel-based alloys, diverge significantly in their composition, production processes, mechanical characteristics, and suitability for specific environments. This article offers a comprehensive exploration of galvanized steel and stainless steel, delving into their metallurgical foundations, manufacturing techniques, physical and chemical properties, corrosion resistance, applications, cost considerations, environmental impacts, and long-term performance. Detailed tables are included to facilitate a scientific comparison between the two materials. Steel, at its core, is an alloy of iron and carbon, with trace amounts of other elements such as manganese, silicon, and phosphorus often Read more

CNC Spinning of Large Center Distance Arc Cam

Computer Numerical Control (CNC) spinning is an advanced manufacturing process that leverages automated machinery to form metal into complex shapes through rotational deformation. Among its many applications, the spinning of large center distance arc cams represents a specialized subset of this technology, blending precision engineering with sophisticated control systems. This article explores the principles, processes, machinery, and scientific underpinnings of CNC spinning as applied to large center distance arc cams, offering a detailed examination of its mechanics, applications, and comparative advantages. Historical Context and Evolution of CNC Spinning The origins of metal spinning trace back to ancient craftsmanship, where artisans manually shaped metal over rotating molds using rudimentary tools. This labor-intensive process evolved significantly with the Industrial Revolution, which introduced Read more

Metal Spinning Tolerance vs Stamping Tolerance

Top 20 Metal Spinning Parts for Electronics

Recent Advances in China Metal Spinning Technology

When spinning various thin-walled cross-section products, the main purpose of spinning is to change the shape of the slab, and the thickness of the slab changes little. This type of spinning is called ordinary spinning. The basic methods of ordinary spinning are: deep drawing spinning (drawing spinning), shrinking spinning (shrinking spinning) and expansion spinning (expanding spinning). What Is Deep drawing spinning Drawing spinning is a forming process that uses radial drawing as the main body to reduce the diameter of the blank (sheet or prefabricated part). It can also be said that it is similar to deep drawing, but it uses a core mold instead of a punch, and a spinning wheel instead of a die. It is the most Read more

Combination of Hemispherical Spinning and 3D Laser Cutting

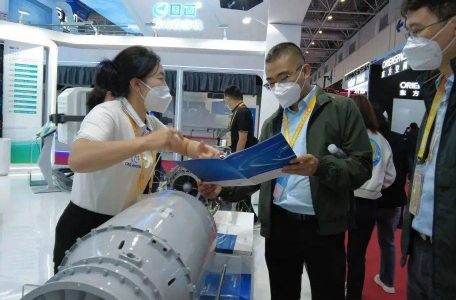

Promoting the Development of the Digital Economy and Stimulating Technological Innovation

Forged, Cast, or Spinning: Which is Lighter, Which is Stronger?

Large Thin-Walled Molybdenum Crucible Spinning Process and Numerical Simulation

Molybdenum crucibles are essential containers used in rare earth smelting furnaces, quartz continuous melting furnaces, and sapphire single crystal growth furnaces. The quality of molybdenum crucibles directly affects the quality of sapphire single crystals, especially in sapphire single crystal production. With the increasing demand for high-quality sapphire single crystals due to the growth of the LED industry, the requirements for molybdenum crucibles have become more stringent. Traditional methods of producing molybdenum crucibles cannot meet the growing demand. This study introduces spinning processing as a new technical approach to address the challenges of producing molybdenum crucibles. High-Temperature Processing: Due to the poor plasticity of pure molybdenum material, spinning processing cannot be completed at room temperature. High-temperature tensile tests show that pure Read more

China Aerospace Corporation Develops the Country’s First and Largest Spinning Machine

Recently, an expert team from the China Aerospace Corporation’s First Academy, Factory 211, conducted a preliminary acceptance review of the CZ3000/2 CNC spinning machine produced by the Seventh Academy’s Factory 7102. This machine is the largest spinning processing machine independently developed in China. It is capable of forming cylindrical, conical, hemispherical, and other curved-line parts from materials such as aluminum alloys, stainless steel, and zirconium oxygen-free copper, meeting specific product process requirements for both cold and hot spinning. The equipment weighs 110 tons, with a maximum single-wheel spinning pressure of 400 kN and a maximum processing diameter of 3 meters. The machine features good stability, ease of operation and maintenance, and reliable safety. It is the first device to utilize Read more

Four-Dimensional Manufacturing and Spin Forming

In July this year, the Lu Wei aluminum wheel hub production line, with a total investment of over 1 billion yuan, began trial operation in Fuzhou, Jiangxi. This is the first digital, continuous, and automated forging aluminum wheel hub production line in China and abroad, marking the industrialization stage of the Demma “Four-Dimensional Manufacturing” project, which has undergone 8 years of research and development. “Four-Dimensional Manufacturing” is an advanced method based on the traditional three-dimensional manufacturing, introducing new mechanical considerations through force counteraction and balance principles to form the “Four-Dimensional Manufacturing” working method. By innovating and transforming traditional equipment such as forging presses, “Four-Dimensional Manufacturing” effectively achieves energy saving, emission reduction, and green manufacturing. For example, in the aluminum wheel Read more

China Builds Asia’s Largest Spinning Machine to Overcome Manufacturing Bottlenecks in Aerospace and Shipbuilding

USA Metal Spinning Components Market By Application

Roof Ventilator (Turbine Ventilator)

Creating Unique Phone Casings with Metal Spinning Technology

Metal Spinning for Aerospace Industries

How to Metal CNC Spinning a Stainless Steel Pot

Why Metal Spinning Is the Optimal Choice for Your Roof Drains This Season

Metal spinning, a metalworking process that dates back centuries, has found its place in various industrial applications due to its efficiency, cost-effectiveness, and ability to produce high-quality parts. One area where metal spinning excels is in the production of roof drains. This article explores why metal spinning is the optimal choice for roof drains this season, delving into the process itself, its benefits, and its application in roofing systems. History of Metal Spinning Metal spinning, also known as spin forming or spinning, is a process that involves the shaping of metal over a rotating mandrel to create axially symmetric parts. This technique has been used for centuries, with origins tracing back to ancient Egypt and China. The process has evolved Read more

Metal spinning, also known as spin forming or spinning, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Historically significant, the process has evolved significantly with advancements in technology, leading to the development of new techniques and applications in various industries. This article provides a comprehensive exploration of metal spinning, covering its history, principles, techniques, materials, equipment, applications, and recent technological advancements. Historical Background Metal spinning has roots that trace back to ancient civilizations, where artisans used simple tools to shape metals into functional objects. Early evidence suggests that metal spinning was practiced in ancient Egypt and China, where metals such as gold, silver, and Read more

CNC Spinning Wheel Hub vs Precision Forging Wheel Hub

In the world of automotive and aerospace engineering, the debate over the most effective and efficient methods for producing wheel hubs is ongoing. Two primary manufacturing techniques stand out: CNC spinning and precision forging. Each method offers unique benefits and poses specific challenges, making them suitable for different applications and industries. This article delves deep into the intricacies of both CNC spinning and precision forging, comparing their processes, advantages, drawbacks, and real-world applications. Understanding Wheel Hubs Wheel hubs are a fundamental component in the wheel assembly of vehicles. They serve as the mounting point for the wheel and the interface for the brake rotor or drum. Wheel hubs house the wheel bearings, facilitating smooth rotation and supporting the vehicle’s weight. Read more

Benefits of Custom Metal Products in the Agricultural Industry

The agricultural industry is the backbone of many economies around the world, providing food, raw materials, and employment to billions of people. As the industry evolves, the need for more efficient, durable, and specialized equipment becomes paramount. Custom metal products have emerged as a vital component in addressing these needs. This article explores the numerous benefits of custom metal products in the agricultural industry, examining their impact on efficiency, durability, innovation, and overall productivity. Enhanced Durability and Longevity One of the primary advantages of custom metal products in agriculture is their enhanced durability and longevity. Agricultural operations often involve exposure to harsh environmental conditions, including extreme temperatures, moisture, and mechanical stress. Custom metal products, tailored to specific agricultural needs, are Read more

Exploring Metal Spinning Thickness Tolerances Across Various Applications

Metal spinning, a versatile manufacturing process, has found widespread applications across industries ranging from aerospace to household goods. One critical aspect influencing the performance and quality of metal spun parts is thickness tolerance. Understanding the nuances of thickness tolerances by application is paramount for achieving desired outcomes in terms of functionality, durability, and aesthetics. In this comprehensive guide, we delve into the intricacies of metal spinning thickness tolerances across diverse applications. From automotive components to architectural elements, we examine how varying tolerances impact the performance and suitability of spun metal parts. Automotive Industry In the automotive industry, where precision and reliability are paramount, metal spinning plays a crucial role in the fabrication of components such as exhaust systems, wheel rims, Read more

China is constructing the largest CNC vertical spinning lathe in Asia for the aerospace industry

Spin forming is a special method of metal plastic forming, where the principle lies in securing the blank on the mold, which, together with the blank, spins at high speed. The outer spinning wheel applies significant pressure to the blank, causing the metal blank to deform, ultimately forming a part identical in shape to the mold. Spin forming can be categorized into ordinary spin forming and strong spin forming. Ordinary spin forming refers to a process where the shape of the blank changes during forming, while the thickness remains constant. This type of spin forming has been around for a long time and finds widespread use in civilian applications such as utensils, tableware, and some parts with low precision requirements. Read more