Composite materials, which combine two or more distinct constituents to achieve superior properties, have become pivotal in advancing technological applications across industries such as aerospace, biomedical engineering, electronics, and environmental remediation. Among the myriad techniques for fabricating composites, spinning processes—particularly electrospinning—and micro-nano processing technologies stand out for their ability to produce materials with tailored microstructures and enhanced functionalities. These methods leverage precise control over material morphology at the micro- and nanoscale, enabling the creation of fibers, films, and structures with unique mechanical, electrical, thermal, and chemical properties. This article provides a comprehensive exploration of the composite process research involving spinning and micro-nano processing technologies, detailing their principles, methodologies, recent advancements, and applications. By synthesizing insights from academic literature and industry developments, this work aims to elucidate the scientific underpinnings and practical implications of these transformative technologies.

Fundamentals of Spinning Processes

Overview of Spinning Techniques

Spinning processes involve the extrusion of a material, typically a polymer solution or melt, through a spinneret to form continuous fibers or filaments. These techniques are critical for producing fibrous composites with high surface-to-volume ratios, which are advantageous for applications requiring enhanced mechanical strength, flexibility, or reactivity. The primary spinning methods relevant to composite fabrication include:

- Wet Spinning: A solution of the polymer is extruded into a coagulation bath, where solvent exchange induces fiber solidification. This method is commonly used for carbon nanotube fibers and biopolymer composites.

- Dry Spinning: The polymer solution is extruded into a gaseous environment, and the solvent evaporates to form solid fibers. This is suitable for polymers with high volatility solvents.

- Melt Spinning: Molten polymer is extruded and cooled to form fibers, often used for thermoplastic composites.

- Electrospinning: An electric field drives the ejection of a polymer jet, which solidifies into ultrafine fibers with diameters ranging from nanometers to micrometers. Electrospinning is particularly significant for micro-nano composites due to its versatility and precision.

Electrospinning: Principles and Parameters

Electrospinning has emerged as a cornerstone of composite process research due to its ability to produce nanofibers with diameters as small as a few nanometers. The process involves applying a high voltage to a polymer solution or melt, creating an electrically charged jet that is drawn toward a grounded collector. As the jet travels, the solvent evaporates or the melt cools, resulting in solid fibers. Key parameters influencing electrospinning include:

- Solution Properties: Viscosity, conductivity, surface tension, and polymer concentration affect fiber morphology. For instance, higher viscosity typically leads to thicker fibers, while increased conductivity can reduce fiber diameter.

- Process Parameters: Applied voltage, flow rate, and the distance between the spinneret and collector (spinning distance) determine jet stability and fiber uniformity. Optimal voltage ensures a stable Taylor cone, while excessive voltage may cause jet instability.

- Environmental Conditions: Temperature and humidity influence solvent evaporation and fiber deposition. High humidity can lead to porous fibers, while elevated temperatures may alter polymer viscosity.

These parameters are critical for tailoring composite fibers for specific applications, such as tissue engineering scaffolds, filtration membranes, or conductive textiles. Recent studies have explored the electrospinning of biopolymers, such as collagen and chitosan, to create bioactive composites with enhanced biocompatibility.

Wet Spinning for Composite Fibers

Wet spinning is particularly relevant for producing composite fibers reinforced with nanomaterials, such as carbon nanotubes (CNTs) or graphene. The process involves dispersing the reinforcing phase (e.g., CNTs) in a polymer solution, which is then extruded into a coagulation bath to form solid fibers. The choice of coagulant—such as acetone, water, or organic solvents—affects fiber morphology and properties. For example, a 2024 study demonstrated that wet-spun CNT fibers using acetone as a coagulant achieved a tensile strength of 1 GPa and electrical conductivity of 2.9 MS m⁻¹, highlighting the role of coagulant selection in optimizing composite performance.

Micro-Nano Processing Technologies

Definition and Scope

Micro-nano processing technologies encompass a suite of fabrication techniques that manipulate materials at the micrometer (10⁻⁶ m) and nanometer (10⁻⁹ m) scales. These methods are essential for creating composite structures with precise geometries, such as thin films, nanoparticles, and three-dimensional (3D) scaffolds. Key micro-nano processing techniques include:

- Lithography: Techniques like photolithography, soft lithography, and dip-pen nanolithography (DPN) pattern surfaces with nanoscale precision.

- Etching: Processes such as reactive ion etching (RIE) and deep reactive ion etching (DRIE) remove material to create micro-nano structures.

- Additive Manufacturing: 3D printing at the micro-nano scale enables the fabrication of complex composite architectures.

- Electrospinning and Electrospraying: These spinning-based methods produce fibers and particles for composite applications.

- Microreactor Technology: Microfluidic systems synthesize nanomaterials with controlled size and morphology.

These techniques are often combined with spinning processes to create hybrid composites with enhanced functionalities, such as graphene-reinforced polymer scaffolds or nanoparticle-embedded fibers.

Lithography for Composite Fabrication

Lithography is a cornerstone of micro-nano processing, enabling the creation of patterned surfaces for composite applications. Soft lithography, which uses elastomeric stamps to transfer patterns, is particularly suited for biological and flexible electronics applications due to its low cost and versatility. For example, a 2010 study utilized soft lithography to fabricate poly(dimethylsiloxane) (PDMS) stamps for microcontact printing, achieving patterns with 30 nm resolution on gold substrates.

Dip-pen nanolithography (DPN) offers even higher precision, using an atomic force microscope tip to deposit molecules with sub-100 nm resolution. This technique has been applied to create nanoarrays of extracellular matrix (ECM) proteins, such as fibronectin, for cell adhesion studies. These lithographic methods are often integrated with spinning processes to create patterned composite scaffolds with tailored biological responses.

Etching and Material Removal

Etching techniques, such as reactive ion etching (RIE), are used to sculpt micro-nano structures in composite materials. A 2025 study on graphite micro-nano processing demonstrated that oxygen-based RIE could etch graphite surfaces to create structures with heights of 29.4–30.9 nm, suitable for microelectromechanical systems (MEMS). Etching is particularly effective for creating high-aspect-ratio features in composites, such as microchannels or nanopores, which enhance fluid transport or electrical conductivity.

Additive Manufacturing at Micro-Nano Scales

Additive manufacturing, particularly 3D printing, has revolutionized micro-nano processing by enabling the fabrication of complex composite structures. Recent advancements in 3D printing achieve sub-micron precision, allowing the production of microelectronic devices, sensors, and biomedical scaffolds. For instance, a 2025 review highlighted the use of 3D printing to create piezoelectric composites for sensors, noting reduced production cycles compared to traditional micromachining.

In composite processing, 3D printing is often combined with spinning techniques to create hybrid structures. For example, graphene-based polymer nanocomposites have been 3D-printed to form scaffolds for bone regeneration, leveraging the electrical conductivity of graphene and the structural flexibility of polymers.

Microreactor Technology for Nanomaterial Synthesis

Microreactors, which operate in continuous or segmented flow modes, provide a controlled environment for synthesizing nanomaterials used in composites. These systems offer precise control over reaction conditions, enabling the production of nanoparticles with uniform size and morphology. A critical review from 2025 noted that microreactors outperform conventional batch processes by overcoming limitations in particle size control and scalability. Spinning disc processing (SDP), a subset of microreactor technology, enhances nanoparticle synthesis by utilizing centrifugal forces to improve mixing and control particle size.

Integration of Spinning and Micro-Nano Processing

Synergistic Approaches

The integration of spinning and micro-nano processing technologies enables the creation of composites with unprecedented properties. For example, electrospinning can produce nanofiber mats, which are then patterned using soft lithography to create structured scaffolds for tissue engineering. Similarly, wet-spun CNT fibers can be etched using RIE to introduce microchannels, enhancing their suitability for flexible electronics.

A notable example is the fabrication of polymer nanocomposites with embedded nanofillers, such as carbon nanotubes or graphene oxide, using a combination of electrospinning and 3D printing. These composites exhibit enhanced mechanical strength, electrical conductivity, and thermal stability, making them ideal for applications in sensors, actuators, and energy storage devices.

Process Optimization and Challenges

Optimizing the integration of spinning and micro-nano processing requires careful consideration of material compatibility, process parameters, and scalability. Key challenges include:

- Dispersion of Nanofillers: Uniform dispersion of nanomaterials, such as CNTs or graphene, in polymer matrices is critical for achieving consistent composite properties. Functionalization techniques, such as covalent or non-covalent modification, are often employed to improve dispersion.

- Scalability: While spinning and micro-nano processing are effective at the laboratory scale, scaling up to industrial production remains a challenge. Microreactor technology and advanced 3D printing systems are being developed to address this issue.

- Material Retention: High-temperature processing, such as sintering, can lead to grain growth, compromising nanoscale features. Rapid sintering methods, like microwave sintering, are being explored to retain nanostructures.

Case Studies

- Electrospun Nanofiber Scaffolds for Tissue Engineering: A 2013 study demonstrated the use of electrospinning to create polyethylene terephthalate (PET) nanofibers, which were patterned using soft lithography to form scaffolds for human umbilical endothelial vein cells (HUVECs). The scaffolds supported cell elongation and proliferation, highlighting the synergy between spinning and micro-nano processing.

- 3D-Printed Graphene-Polymer Composites: A 2021 study utilized 3D printing to fabricate graphene-reinforced polymer scaffolds for bone regeneration. The scaffolds exhibited enhanced mechanical properties and bioactivity, attributed to the precise control over graphene dispersion and scaffold architecture.

- Wet-Spun CNT Fibers for Electronics: A 2024 study reported the wet spinning of CNT fibers with a tensile strength of 1 GPa and electrical conductivity of 2.9 MS m⁻¹, achieved by optimizing the coagulation bath composition. These fibers were subsequently etched to create microchannels, enhancing their performance in flexible electronics.

Applications of Composite Processes

Biomedical Applications

Composite materials fabricated via spinning and micro-nano processing are widely used in biomedical applications, including tissue engineering, drug delivery, and biosensing. Electrospun nanofiber scaffolds, for instance, mimic the extracellular matrix, providing a biocompatible environment for cell growth. A 2024 study highlighted the use of strontium-doped bioglass-laden gelatin methacryloyl hydrogels, fabricated via electrospinning, for vital pulp therapy.

In drug delivery, microreactor-synthesized nanoparticles are embedded in electrospun fibers to create controlled-release systems. These composites respond to environmental stimuli, such as pH or temperature, to release therapeutic agents.

Electronics and Sensors

The high electrical conductivity and mechanical flexibility of composites make them ideal for electronics and sensors. Wet-spun CNT fibers and 3D-printed graphene-polymer composites are used in flexible electrodes, conductive inks, and piezoelectric sensors. A 2019 study reported the fabrication of magnetic and luminescent polymer-based microstructures using mask lithography and 3D printing, demonstrating their potential for multifunctional sensors.

Environmental Remediation

Polymer nanocomposites (PNCs) fabricated via spinning and micro-nano processing are effective catalysts for environmental remediation. A 2025 review detailed the use of PNCs in catalytic processes, such as redox degradation and electrocatalytic degradation, to remove pollutants from water and air. The high surface area of nanofillers enhances catalytic efficiency, while the polymer matrix facilitates separation and reuse.

Energy Storage and Conversion

Composites are critical for energy storage and conversion devices, such as batteries, supercapacitors, and solar cells. Graphene-reinforced polymer composites, fabricated via 3D printing, exhibit high electrical conductivity and mechanical stability, making them suitable for electrodes and current collectors. A 2023 study highlighted the use of nanocomposites in fuel cells, noting their enhanced catalytic activity and light absorption.

Recent Advances and Future Directions

Innovations in Material Design

Recent advances in composite process research focus on developing multifunctional materials with tailored properties. Self-healing nanocomposites, which repair damage autonomously, are a promising area of study. These materials combine responsive polymers with nanofillers, such as graphene or metal oxides, to achieve both mechanical and functional recovery.

Another innovation is the integration of nanotechnology with 3D printing to create complex structures with hierarchical architectures. For example, biofabrication techniques, such as inkjet bioprinting, enable the precise positioning of cells and biomaterials in 3D-printed scaffolds, advancing tissue engineering applications.

Computational Modeling and Machine Learning

Computational modeling and machine learning are transforming composite process research by predicting material properties and optimizing process parameters. A 2021 study used physics-informed machine learning to discover energy materials, demonstrating its potential for designing nanocomposites with enhanced electrical and thermal properties. These tools are particularly valuable for optimizing the dispersion of nanofillers and predicting the performance of complex composite structures.

Sustainability and Scalability

Sustainability is a growing focus in composite processing, with research emphasizing eco-friendly materials and energy-efficient processes. Biopolymers, such as chitosan and cellulose, are increasingly used in electrospinning to create biodegradable composites. Additionally, microreactor technology and rapid sintering methods reduce energy consumption and waste, addressing scalability challenges.

Future Research Directions

Future research should address the following areas:

- Hybrid Processing Techniques: Combining spinning, lithography, and 3D printing to create multifunctional composites with integrated electronics and biological components.

- Scalable Manufacturing: Developing continuous processing systems, such as roll-to-roll electrospinning and high-throughput 3D printing, to enable industrial-scale production.

- Advanced Characterization: Utilizing techniques like atomic force microscopy (AFM) and scanning electron microscopy (SEM) to study the interfacial interactions and microstructure of composites at the nanoscale.

- Regulatory and Safety Considerations: Establishing guidelines for the safe use of nanocomposites, particularly in biomedical and environmental applications, to ensure biocompatibility and environmental impact are addressed.

Comparative Analysis of Techniques

The following tables compare the key features, advantages, and limitations of spinning and micro-nano processing techniques used in composite fabrication.

Table 1: Comparison of Spinning Techniques

| Technique | Principle | Fiber Diameter | Materials | Advantages | Limitations |

|---|---|---|---|---|---|

| Wet Spinning | Extrusion into coagulation bath for solvent exchange | 1–100 µm | Polymers, CNTs, graphene | High strength, suitable for nanofillers | Complex coagulation bath optimization, limited to certain solvents |

| Dry Spinning | Extrusion into gaseous environment for solvent evaporation | 10–100 µm | Polymers with volatile solvents | Simple setup, high throughput | Limited to volatile solvents, larger fiber diameters |

| Melt Spinning | Extrusion of molten polymer followed by cooling | 10–500 µm | Thermoplastics | High production rate, no solvent required | High temperatures, unsuitable for thermosets or nanofillers |

| Electrospinning | Electric field-driven jet formation and solvent evaporation | 10 nm–10 µm | Polymers, biopolymers, nanocomposites | Nanoscale fibers, high surface area, versatile | Low throughput, requires high voltage, parameter optimization |

Table 2: Comparison of Micro-Nano Processing Techniques

| Technique | Principle | Resolution | Applications | Advantages | Limitations |

|---|---|---|---|---|---|

| Photolithography | Light-based patterning through masks | 100 nm–1 µm | Microelectronics, MEMS | High precision, mature technology | Expensive equipment, limited to planar surfaces |

| Soft Lithography | Elastomeric stamp-based pattern transfer | 30 nm–1 µm | Biological scaffolds, flexible electronics | Low cost, versatile, suitable for soft materials | Limited to specific substrates, lower resolution than photolithography |

| Dip-Pen Nanolithography | Molecular deposition via AFM tip | 10–100 nm | Nanoarrays, biosensors | Ultra-high resolution, precise chemical patterning | Slow process, limited scalability |

| Reactive Ion Etching | Plasma-based material removal | 10 nm–1 µm | MEMS, microchannels | High aspect ratios, precise control | Requires vacuum systems, material-specific etchants |

| 3D Printing | Layer-by-layer material deposition | 100 nm–10 µm | Scaffolds, sensors, microelectronics | Complex geometries, material versatility | Limited resolution at nanoscale, material compatibility issues |

| Microreactor Technology | Controlled synthesis in microchannels | 1–100 nm | Nanoparticles, composites | Uniform particle size, scalable, energy-efficient | Complex setup, limited to liquid-phase reactions |

Conclusion

The composite process research of spinning and micro-nano processing technologies represents a dynamic and rapidly evolving field with significant implications for materials science and engineering. By leveraging the precision of electrospinning, wet spinning, and advanced micro-nano fabrication techniques, researchers have developed composites with tailored properties for applications ranging from biomedical scaffolds to flexible electronics and environmental catalysts. Despite challenges in scalability, dispersion, and material retention, ongoing innovations in hybrid processing, computational modeling, and sustainable materials are poised to overcome these barriers. As the field progresses, interdisciplinary collaboration and advanced characterization will be critical for unlocking the full potential of these technologies, paving the way for next-generation composite materials that address global challenges in health, energy, and the environment.

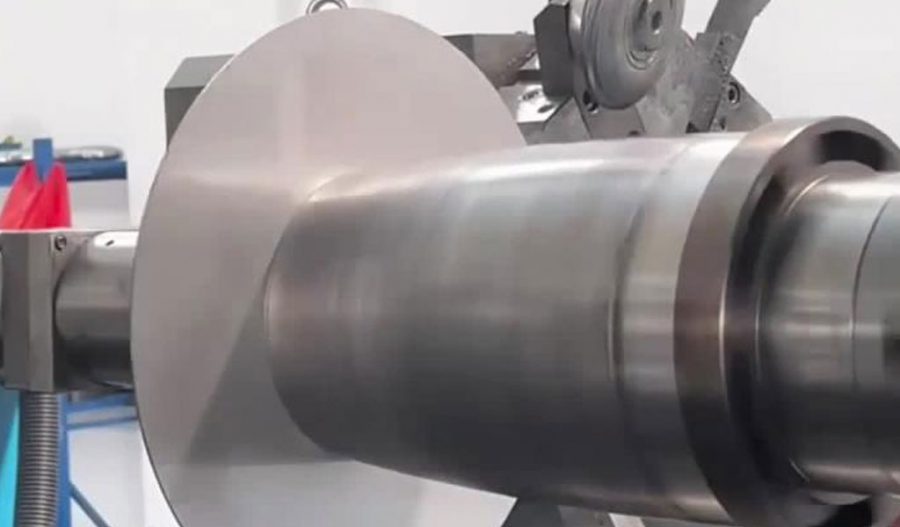

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,