The integration of advanced manufacturing technologies has revolutionized the production of high-performance components across industries such as aerospace, automotive, biomedical, and energy. Among these technologies, Computer Numerical Control (CNC) spinning and additive manufacturing (AM) have emerged as pivotal processes, each offering unique capabilities in shaping materials with precision and efficiency. CNC spinning, a traditional subtractive and forming technique, excels in producing rotationally symmetric components with superior surface finishes and structural integrity. Additive manufacturing, often referred to as 3D printing, enables the fabrication of complex geometries layer by layer, offering unparalleled design flexibility and material efficiency. The convergence of these two processes—termed composite process research—seeks to harness their complementary strengths, addressing limitations inherent in each when used independently. This article provides Read more

Blog

Adaptive Optimization of Spinning Path Based on Reinforcement Learning

The optimization of spinning paths in mechanical systems, robotics, and industrial automation has long been a critical area of research, driven by the need to enhance efficiency, reduce energy consumption, and improve operational precision. Spinning path optimization involves determining the most effective trajectory for a rotating object or mechanism, such as a robotic arm, a spinning tool, or a vehicle navigating a curved path. Traditional approaches to path optimization often rely on deterministic algorithms or heuristic methods, which may struggle to adapt to dynamic environments or complex constraints. In recent years, reinforcement learning (RL), a subset of machine learning, has emerged as a powerful tool for addressing these challenges by enabling adaptive, data-driven optimization of spinning paths. Reinforcement learning is Read more

Design of Complex Component Spinning Based on Topology Optimization

Topology optimization is a mathematical method used in engineering design to optimize material distribution within a given design space, aiming to achieve the best structural performance while adhering to specific constraints such as weight, volume, or manufacturing limitations. When applied to the design of complex component spinning—a manufacturing process where a flat metal disc or tube is rotated at high speed and formed into an axially symmetric part—topology optimization offers significant potential to enhance efficiency, reduce material usage, and improve mechanical performance. This article explores the integration of topology optimization in the spinning process for complex components, delving into its theoretical foundations, practical applications, computational methodologies, and comparative analyses with traditional design approaches. The discussion is structured to provide a Read more

Regulation Mechanism of Stress Distribution in CNC Spinning of Conical Components

Computer Numerical Control (CNC) spinning is a sophisticated metal forming process that leverages automated machinery to shape metal sheets or tubes into axisymmetric components through localized plastic deformation. This technique, an evolution of traditional manual spinning, employs programmable machine tools to achieve high precision, repeatability, and efficiency. CNC spinning is particularly valued in industries such as aerospace, automotive, and energy for producing complex geometries like conical components, which are characterized by their tapered, axisymmetric profiles. These components are integral to applications ranging from rocket nozzles and satellite dishes to exhaust cones and pressure vessel heads, where structural integrity and dimensional accuracy are paramount. Conical components, due to their geometry, pose unique challenges in manufacturing. The tapering profile induces non-uniform stress Read more

Relationship Between Grain Boundary Slip and Material Strength in Metal Spinning

Metal spinning, a versatile manufacturing process, involves the shaping of sheet metal into axisymmetric components through localized plastic deformation. This technique, widely used in industries such as aerospace, automotive, and medical device manufacturing, relies on the controlled application of force to deform a rotating metal blank over a mandrel. The mechanical properties of the resulting components, particularly their strength, are profoundly influenced by the microstructure of the material, with grain boundaries playing a pivotal role. Grain boundaries, the interfaces between crystalline grains in polycrystalline metals, are critical microstructural features that govern deformation mechanisms, including grain boundary slip (GBS). GBS refers to the relative sliding of adjacent grains along their boundaries under applied stress, a phenomenon that becomes particularly significant at Read more

Application of Smart Sensors and the Internet of Things in the Spinning Industry

The spinning industry, a cornerstone of textile manufacturing, transforms raw fibers into yarns through complex mechanical processes. With the advent of Industry 4.0, the integration of smart sensors and the Internet of Things (IoT) has revolutionized this sector, enhancing efficiency, quality, and sustainability. Smart sensors, characterized by their ability to collect, process, and transmit data autonomously, combined with IoT’s networked connectivity, enable real-time monitoring, predictive maintenance, and data-driven decision-making. This article explores the multifaceted applications of these technologies in the spinning industry, detailing their technical underpinnings, operational impacts, and future potential. It examines their role in process optimization, quality control, energy management, supply chain integration, and worker safety, supported by comparative tables and case studies. Historical Context and Technological Evolution Read more

Effect of Lubricant Type on Friction and Forming Effect in Spinning Process

The spinning process, a subset of metal forming techniques, involves the gradual deformation of a rotating metal blank or preform into a desired shape, typically axisymmetric, using a roller or tool that applies localized pressure. This process is widely utilized in industries such as aerospace, automotive, and consumer goods manufacturing for producing components like pressure vessels, wheel rims, and cookware. Central to the efficacy of the spinning process is the management of friction at the interface between the tool and the workpiece, as well as the resulting forming effects, which dictate the quality, precision, and efficiency of the final product. Lubricants play a critical role in modulating friction, influencing material flow, surface quality, tool wear, and energy consumption during spinning. Read more

Comparative Study of Forming Quality in High-Speed Spinning and Conventional Spinning

Metal spinning, a versatile sheet metal forming process, involves rotating a metal blank or tube at high speed while applying localized pressure to shape it over a mandrel or form. This technique, rooted in ancient craftsmanship, has evolved into a sophisticated manufacturing method used across industries such as aerospace, automotive, and consumer goods. Two primary approaches dominate modern metal spinning: conventional spinning and high-speed spinning. Conventional spinning relies on gradual, often manual or semi-automated deformation, while high-speed spinning leverages advanced machinery, higher rotational speeds, and optimized process parameters to enhance productivity and precision. This article provides a comprehensive comparative study of the forming quality of these two methods, analyzing their mechanics, process parameters, material behavior, and outcomes. Detailed tables and Read more

Pad printing and screen printing represent two distinct methodologies within the broader field of industrial and commercial printing technologies. Both techniques are widely utilized across various industries for applying ink to substrates, ranging from consumer goods to specialized technical components. Pad printing, also known as tampography, involves transferring a two-dimensional image from an etched plate onto a three-dimensional object using a silicone pad. Screen printing, conversely, employs a mesh screen through which ink is forced onto a flat or semi-flat surface, creating a design via a stencil-based process. These processes, while sharing the common goal of image transfer, diverge significantly in their mechanisms, applications, and technical attributes. The origins of these printing methods reflect their evolution from traditional craftsmanship to Read more

Effect of the Gap Between the Spinning Wheel and the Die on Forming Force in Metal Spinning

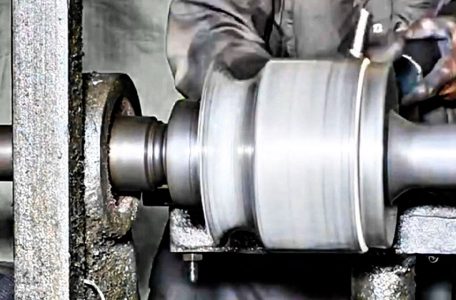

Metal spinning, also known as spin forming or metal turning, is a metalworking process that involves rotating a metal disc or tube at high speed to form axially symmetric parts. This chipless forming technique, which dates back to ancient civilizations such as Egypt and China, has evolved into a sophisticated manufacturing method widely used in industries ranging from aerospace to automotive and consumer goods. The process typically employs a lathe, where a metal blank is clamped against a mandrel (or die) and shaped by a spinning wheel or roller that applies localized force to deform the material over the die. The quality, efficiency, and mechanical properties of the spun part depend on several process parameters, including the mandrel speed, feed Read more

Control Methods for Springback Phenomenon in Metal Spinning

Metal spinning, a versatile sheet metal forming process, is widely employed in industries such as aerospace, automotive, and manufacturing to produce axisymmetric components with high precision and complex geometries. The process involves rotating a metal blank or preform at high speed while a forming tool, typically a roller, applies localized pressure to deform the material against a mandrel, shaping it into the desired form. Despite its advantages, including flexibility, low tooling costs, and the ability to form lightweight, high-strength components, metal spinning is challenged by the springback phenomenon—a critical issue that affects dimensional accuracy and product quality. Springback refers to the elastic recovery of a material after the removal of forming forces, resulting in a deviation from the intended shape. Read more

Design and Application of Multi-Point Contact Spinning Wheel in Spinning Process

The spinning wheel, a cornerstone of textile production for centuries, has undergone significant evolution since its inception, likely in the Middle East or India around the 11th century. From its rudimentary forms to modern mechanized iterations, the spinning wheel has been pivotal in transforming raw fibers into yarn, a process fundamental to the textile industry. Among the myriad advancements in spinning technology, the development of the multi-point contact spinning wheel represents a significant leap forward, particularly in enhancing efficiency, yarn quality, and adaptability to diverse fiber types. This article delves into the design principles, mechanical intricacies, and practical applications of the multi-point contact spinning wheel in the spinning process, exploring its historical context, technical innovations, and impact on modern textile Read more

Spinning in the Manufacturing of High-Speed Rail Parts

Spinning, also known as spin forming or metal spinning, is a metalworking process used to form axially symmetric parts by rotating a metal blank or tube at high speed while applying localized pressure with a tool. This technique has been employed for centuries in various industries, from aerospace to automotive, and has gained significant traction in the manufacturing of high-speed rail (HSR) components due to its precision, cost-effectiveness, and ability to produce lightweight, high-strength parts. In the context of high-speed rail, spinning is critical for fabricating components such as wheelsets, axles, and structural elements that must withstand extreme dynamic loads, high speeds, and stringent safety requirements. High-speed rail systems, defined as rail transport networks with trains operating at speeds exceeding Read more

Spinning in the Nuclear Industry

The nuclear industry, encompassing both fission and fusion technologies, relies on a multitude of physical and engineering principles to harness energy from atomic nuclei. Among these, the concept of “spinning” plays a surprisingly multifaceted role, with applications ranging from the microscopic behavior of nuclear spins to macroscopic mechanical spinning in centrifuge technologies. In the context of nuclear science, spinning refers to both the intrinsic angular momentum of subatomic particles (nuclear spin) and the physical rotation of mechanical systems used in processes like uranium enrichment or reactor component testing. These applications are critical to the efficiency, safety, and advancement of nuclear technologies, influencing everything from fuel production to waste management and experimental research. This article explores the special applications of spinning Read more

Comparison of Cold Working and Hot Working in Metal Spinning

Metal spinning, also known as spin forming or metal turning, is a metalworking process used to form axially symmetric parts by rotating a metal blank or tube at high speed while applying localized pressure with a tool to shape it against a mandrel. This technique is widely employed in industries such as aerospace, automotive, and consumer goods manufacturing to produce components like cookware, lighting fixtures, and rocket nose cones. The process can be performed under different thermal conditions, primarily categorized as cold working and hot working, each imparting distinct mechanical, structural, and economic outcomes to the final product. This article provides a comprehensive comparison of cold working and hot working in metal spinning, exploring their definitions, processes, material behaviors, applications, Read more

Application of Spinning in Aircraft Engine Parts

Spinning, a metalworking process involving the deformation of a rotating metal blank or preform over a mandrel, has emerged as a critical manufacturing technique in the aerospace industry, particularly for the production of aircraft engine components. This process, often referred to as metal spinning or spin forming, allows for the creation of seamless, axisymmetric parts with high precision, structural integrity, and material efficiency. In the context of aircraft engines, spinning is employed to fabricate components such as compressor and turbine disks, fan blades, combustor liners, and exhaust nozzles, which must withstand extreme temperatures, pressures, and mechanical stresses. The application of spinning in aircraft engine manufacturing represents a confluence of advanced materials science, precision engineering, and aerodynamic design, contributing to the Read more

Application of Spinning in Metal Sculpture Art

Metal spinning, also known as spin forming or metal turning, is a metalworking process by which a flat metal disc or tube is rotated at high speed and formed into an axially symmetric part using tools. This technique, rooted in ancient craftsmanship, has evolved into a sophisticated method employed in various industries, including aerospace, automotive, and notably, the creation of metal sculpture art. In the context of sculpture, metal spinning offers artists a unique ability to craft intricate, seamless, and symmetrical forms that are both aesthetically compelling and structurally robust. This article explores the historical development, technical principles, artistic applications, and contemporary innovations of metal spinning in metal sculpture art, delving into its cultural significance, material considerations, and comparative advantages Read more

Flexible Mold Technology in Spinning Processing

Flexible mold technology in spinning processing represents a transformative approach in the field of metal forming, enabling the production of complex, high-precision components with enhanced efficiency and adaptability. Spinning, a metalworking process that forms sheet metal or tubular blanks into rotationally symmetric or asymmetric shapes, has evolved significantly with the integration of flexible mold systems. Unlike traditional rigid molds, flexible molds allow for rapid reconfiguration, reduced setup times, and the ability to produce small-batch, customized parts economically. This article provides a comprehensive exploration of flexible mold technology in spinning processing, covering its principles, historical development, technical advancements, applications, challenges, and future prospects. Through detailed analysis and comparative tables, it aims to elucidate the scientific and industrial significance of this innovative Read more

Application of Spinning in Marine Engineering

The origins of metal spinning can be traced back to ancient civilizations, where artisans used rudimentary tools to shape metals into vessels and decorative items. However, its adoption in marine engineering began in earnest during the Industrial Revolution, when advancements in machinery enabled precise control over rotational speeds and forming pressures. By the late 19th century, spinning was employed to fabricate components for steamships, such as boiler fittings and propeller hubs, which required uniform thickness and structural integrity. In the 20th century, the advent of computer numerical control (CNC) spinning machines revolutionized the process, allowing for greater precision and repeatability. This was particularly significant in marine engineering, where components like propeller blades, sonar domes, and pressure hulls demanded exacting tolerances Read more

Application of Spinning in Rail Transportation

Spinning, a metalworking process involving the deformation of a rotating metal workpiece to form axially symmetric components, has found significant applications in rail transportation. This technique, rooted in ancient craftsmanship but refined through modern engineering, enables the production of high-strength, lightweight, and precise components critical to the performance, safety, and efficiency of rail systems. From the manufacturing of wheels and axles to the fabrication of structural components and specialized parts, spinning has become integral to the rail industry. This article explores the historical evolution, technical principles, specific applications, material considerations, manufacturing advancements, economic impacts, and future prospects of spinning in rail transportation, providing a comprehensive overview supported by comparative data. Historical Context of Spinning in Rail Transportation The origins of Read more

Technology of Spinning in the Manufacture of Metal Bellows

Metal bellows are precision-engineered, flexible components designed to accommodate axial, lateral, and angular movements while maintaining a hermetic seal. These versatile structures are critical in industries such as aerospace, semiconductor manufacturing, medical devices, and oil and gas, where they serve as actuators, seals, expansion joints, and sensors. The manufacturing of metal bellows involves several techniques, including hydroforming, edge-welding, and electroforming, but one of the foundational processes for creating seamless bellows is metal spinning, also known as spin forming. This article explores the technology of spinning in the manufacture of metal bellows, delving into its historical evolution, technical principles, material considerations, process variations, and modern advancements. Detailed comparisons of spinning with other bellows manufacturing methods are provided to highlight its unique Read more

The Role of Spinning in the Manufacturing of Drone Parts

Spinning, a metalworking process that involves rotating a metal disc or tube at high speed while applying localized pressure to shape it, plays a pivotal role in the manufacturing of drone components. Known as metal spinning or spin forming, this technique has been adapted to meet the demands of modern aerospace applications, particularly in the burgeoning field of unmanned aerial vehicles (UAVs), commonly referred to as drones. The process is valued for its ability to produce lightweight, high-strength, and seamless parts, which are critical for the performance, efficiency, and reliability of drones used in commercial, military, and recreational applications. This article explores the historical context, technical principles, material considerations, applications, advantages, challenges, and future trends of spinning in drone part Read more

Comprehensive Overview of Hydroforming Technology

Hydroforming is a specialized manufacturing process used to shape ductile metals, such as aluminum, brass, copper, steel, and stainless steel, into structurally robust, lightweight components. This technique employs high-pressure hydraulic fluid to press metal into a die, enabling the creation of complex geometries that are often unattainable through conventional metal-forming methods like stamping or forging. Hydroforming is widely utilized across industries, including automotive, aerospace, plumbing, and consumer goods, due to its ability to produce parts with high strength-to-weight ratios, minimal material waste, and enhanced structural integrity. This article provides an in-depth exploration of hydroforming, covering its principles, processes, equipment, materials, applications, advantages, limitations, and future trends, with a focus on scientific rigor and technical detail. 1. Introduction to Hydroforming 1.1 Read more

Which One Withstands Constant Sunlight Exposure?

Constant sunlight exposure poses significant challenges to materials, surfaces, and living organisms due to the intense ultraviolet (UV) radiation, thermal energy, and photochemical reactions it induces. Understanding which materials and organisms can withstand prolonged exposure to sunlight is critical for applications in architecture, agriculture, aerospace, and environmental science. This article explores the resilience of various materials (e.g., metals, polymers, coatings, and textiles) and biological entities (e.g., plants, microorganisms, and human skin) under constant sunlight exposure. It examines the mechanisms of degradation, protective strategies, and comparative performance through empirical data and theoretical frameworks. Introduction Sunlight, a primary source of energy for Earth’s ecosystems, consists of electromagnetic radiation spanning ultraviolet (UV, 100–400 nm), visible (400–700 nm), and infrared (IR, >700 nm) wavelengths. Read more

The Ultimate Checklist for Identifying Good Welds

Welding is a critical fabrication process used to join metals or thermoplastics by applying heat, pressure, or both, resulting in a strong, permanent bond. The quality of a weld directly impacts the structural integrity, safety, and longevity of the welded component. Identifying a good weld requires a systematic evaluation of multiple factors, including visual characteristics, mechanical properties, and compliance with industry standards. This article provides a comprehensive, scientifically structured checklist for assessing weld quality, encompassing visual inspection, non-destructive testing (NDT), destructive testing, and adherence to codes and standards. Designed for welders, inspectors, engineers, and quality control professionals, this guide includes detailed explanations, comparative tables, and references to authoritative standards such as those from the American Welding Society (AWS), International Organization Read more

Safety Under Pressure: Pressure Vessel Shape Matters

Pressure vessels are critical components in numerous industrial, commercial, and scientific applications, designed to contain gases or liquids at pressures substantially different from the ambient environment. These vessels are integral to processes in industries such as petrochemical, pharmaceutical, nuclear, and aerospace engineering. The safety, efficiency, and longevity of pressure vessels are heavily influenced by their geometric design, material selection, and operational conditions. Among these factors, the shape of a pressure vessel plays a pivotal role in determining its ability to withstand internal pressures, resist external forces, and ensure operational safety. This article explores the significance of pressure vessel shape in ensuring safety under pressure, delving into the engineering principles, material considerations, and practical applications that govern their design. Through a Read more

Difficulties in Metal Spinning Special Alloys

Metal spinning, also known as spin forming or centrifugal forming, is a metalworking process that involves rotating a metal disc or tube at high speeds while applying localized pressure to shape it into axially symmetric components. This technique is valued for its ability to produce seamless, high-strength parts with minimal material waste, making it a preferred method in industries such as aerospace, automotive, defense, and energy. While metal spinning is versatile and compatible with a wide range of materials, working with special alloys—such as high-strength, high-temperature, or corrosion-resistant alloys like Hastelloy, Inconel, titanium, and magnesium alloys—presents unique challenges. These difficulties stem from the complex mechanical, thermal, and metallurgical properties of special alloys, which demand advanced techniques, precise control, and specialized Read more

Hydroforming Magnetic and Rotary Pumps

Hydroforming, magnetic drive systems, and rotary pump technologies represent advanced engineering solutions that have significantly impacted various industries, including chemical processing, medical device manufacturing, automotive, and aerospace. This article provides a comprehensive exploration of hydroforming as applied to magnetic and rotary pumps, delving into their principles, designs, applications, advantages, limitations, and future prospects. The tone and structure aim to mirror the rigor and neutrality of a scientific encyclopedia, with detailed comparisons presented in tables to enhance clarity and utility. Introduction Hydroforming is a specialized metal-forming process that utilizes high-pressure hydraulic fluid to shape ductile metals, such as aluminum, stainless steel, and titanium, into complex geometries. The process is particularly valued for producing lightweight, high-strength components with minimal material waste, making Read more

What Is Large Basin CNC Metal Spinning

Large basin CNC metal spinning is a sophisticated manufacturing process used to create large, axisymmetric, seamless metal components, typically with diameters exceeding 1 meter (39 inches) and often used in industries such as aerospace, energy, chemical processing, and industrial manufacturing. This process involves rotating a flat metal disc or preformed blank at high speeds on a computer numerically controlled (CNC) spinning lathe while applying localized pressure with a roller tool to shape the metal over a mandrel or chuck into a desired form, such as a deep basin, hemispherical dome, or cylindrical vessel. The term “large basin” refers to the substantial size and volume of the components produced, which are often used as tanks, pressure vessels, or structural parts requiring Read more

The Importance of Shell Nosing in Metal Spinning

Metal spinning, also known as spin forming or metal turning, is a metalworking process that transforms a flat metal disc or tube into axially symmetric parts through high-speed rotation and localized plastic deformation. This ancient technique, with roots traceable to Ancient Egypt, has evolved into a sophisticated manufacturing method used across industries such as aerospace, automotive, and defense. A critical yet often underexplored aspect of metal spinning is shell nosing, a specialized process that involves forming the open end of a spun metal shell into a tapered, rounded, or otherwise contoured shape. Shell nosing enhances the structural integrity, functionality, and aesthetic appeal of spun components, making it a pivotal operation in the production of high-precision parts like artillery shells, rocket Read more