Computer Numerical Control (CNC) spinning, a sophisticated metal-forming process, has emerged as a pivotal technology in the manufacturing of defense equipment. This advanced technique involves the use of computer-controlled machinery to shape metal workpieces into axially symmetric components through high-speed rotation and precise tool application. CNC spinning is distinguished by its ability to produce high-strength, lightweight, and complex geometries with exceptional precision, making it indispensable in the defense sector, where components must meet stringent performance and reliability standards. The industrialization of CNC spinning in defense equipment manufacturing represents a convergence of technological innovation, material science, and industrial engineering, driven by the need for enhanced military capabilities, cost efficiency, and rapid production scalability.

The defense industry relies on CNC spinning to fabricate critical components such as missile casings, radar domes, warship propulsion elements, and aircraft structural parts. These components demand materials with high strength-to-weight ratios, corrosion resistance, and the ability to withstand extreme environmental conditions. CNC spinning’s versatility in processing advanced alloys, including titanium, aluminum, and high-strength steels, positions it as a cornerstone of modern defense manufacturing. This article explores the industrialization of CNC spinning, tracing its historical development, technical advancements, applications in defense, and the challenges and future prospects of its widespread adoption. By examining recent research, industry trends, and comparative analyses, this comprehensive study aims to provide a definitive resource on the role of CNC spinning in shaping the future of defense equipment manufacturing.

Historical Context of CNC Spinning in Manufacturing

Origins of Metal Spinning

Metal spinning, also known as spin forming or spin forging, dates back to ancient civilizations, where artisans manually shaped metals using rudimentary tools. Early applications included the creation of decorative vessels and rudimentary tools, often crafted from soft metals like copper or bronze. The process involved rotating a metal disc or tube on a lathe while applying pressure with a tool to form the desired shape. While effective for simple geometries, manual spinning was labor-intensive, lacked precision, and was limited in its ability to handle complex or high-strength materials.

The Industrial Revolution marked a turning point for metal spinning, as mechanized lathes and improved tooling enabled greater consistency and scalability. By the early 20th century, metal spinning found applications in industries such as automotive and aerospace, where lightweight, symmetrical components were in demand. However, the process remained semi-manual, relying heavily on the skill of the operator, which constrained its adoption in high-precision fields like defense.

Emergence of CNC Technology

The advent of Computer Numerical Control (CNC) technology in the mid-20th century revolutionized metal spinning. CNC systems, which use computer programming to control machinery, were first developed in the 1940s and 1950s through collaborations between the U.S. military and industrial partners, notably John T. Parsons, who pioneered numerical control for manufacturing helicopter blades. By integrating digital controls with spinning lathes, CNC spinning enabled unprecedented precision, repeatability, and automation, transforming the process into a viable method for producing complex defense components.

The defense industry, driven by the Cold War’s demand for advanced weaponry and aerospace systems, was an early adopter of CNC spinning. The ability to produce seamless, high-strength components with minimal material waste aligned with the military’s need for reliable, lightweight equipment. For example, CNC spinning was used to fabricate missile nose cones and aircraft engine components, where tight tolerances and structural integrity were paramount. The technology’s evolution was further accelerated by advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM), which allowed engineers to design intricate geometries and translate them directly into machine instructions.

Evolution in Defense Applications

By the late 20th century, CNC spinning had become a standard process in defense manufacturing, supported by investments in research and development (R&D) from governments and private industry. The U.S. Department of Defense (DoD), through initiatives like the Accelerated Training in Defense Manufacturing (ATDM) program, prioritized the development of advanced manufacturing techniques, including CNC spinning, to support the submarine industrial base and other critical defense sectors. The technology’s ability to produce large, seamless components, such as warship propeller shafts and tank turret rings, made it a strategic asset in military production.

The industrialization of CNC spinning was also driven by the need for rapid prototyping and high-mix, low-volume production, characteristics inherent to defense manufacturing. Unlike traditional manufacturing methods like casting or forging, which require expensive tooling and long lead times, CNC spinning offers flexibility and cost efficiency, enabling manufacturers to adapt to evolving design requirements. This adaptability has been critical in the development of next-generation defense systems, including unmanned aerial vehicles (UAVs), hypersonic missiles, and advanced radar systems.

Technical Principles of CNC Spinning

Fundamentals of the CNC Spinning Process

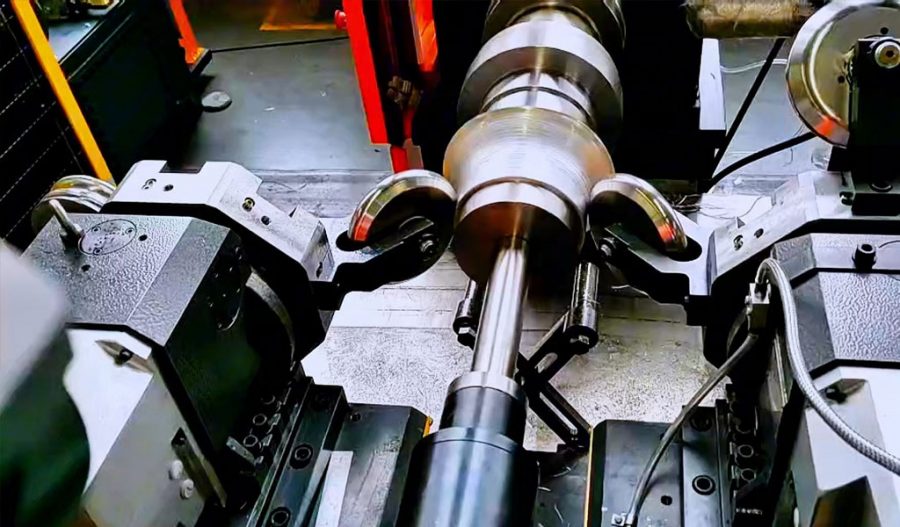

CNC spinning is a chipless metal-forming process that shapes a rotating metal workpiece, typically a disc or tube, into an axially symmetric part by applying controlled pressure with a forming tool. The workpiece is clamped onto a spinning mandrel, which defines the inner geometry of the final component, and rotated at high speeds, often exceeding 1,000 revolutions per minute (RPM). A CNC-controlled tool, guided by precise programming, incrementally deforms the metal, stretching and thinning it to conform to the mandrel’s shape.

The process can be categorized into two primary types: conventional spinning and shear spinning. Conventional spinning maintains the workpiece’s original thickness, shaping it through radial and axial deformation. Shear spinning, also known as power spinning, reduces the workpiece’s thickness by applying significant compressive forces, resulting in stronger, thinner-walled components. Both techniques are widely used in defense manufacturing, with shear spinning being particularly suited for high-strength applications like missile casings.

Key Components of CNC Spinning Systems

A typical CNC spinning machine comprises several critical components:

- Spindle and Mandrel: The spindle rotates the workpiece at high speeds, while the mandrel provides the template for the component’s inner geometry. Mandrels are often made from hardened steel or composite materials to withstand repeated forming cycles.

- Forming Tool: The tool, typically a roller or pointed instrument, applies pressure to the workpiece. Advanced systems use multiple tools to achieve complex shapes and improve efficiency.

- CNC Controller: The controller interprets CAD/CAM instructions, coordinating the tool’s movements with the spindle’s rotation to achieve precise deformation.

- Tailstock: The tailstock secures the workpiece against the mandrel, ensuring stability during high-speed rotation.

- Cooling and Lubrication Systems: These systems manage heat generated during forming, preventing material degradation and extending tool life.

Modern CNC spinning machines incorporate advanced features such as multi-axis control, real-time monitoring, and adaptive feedback systems, which enhance precision and reduce defects. For example, 5-axis CNC spinning machines, which allow simultaneous movement in multiple directions, are increasingly used for complex defense components.

Materials Used in CNC Spinning

CNC spinning is compatible with a wide range of materials, making it ideal for defense applications. Commonly used materials include:

- Aluminum Alloys: Lightweight and corrosion-resistant, aluminum alloys like 6061 and 7075 are used for aircraft components and radar domes.

- Titanium Alloys: Known for their high strength-to-weight ratio and resistance to extreme temperatures, titanium alloys like Ti-6Al-4V are used in missile casings and engine parts.

- High-Strength Steels: Stainless steels and maraging steels are used for components requiring durability, such as tank turret rings and warship propulsion systems.

- Nickel-Based Superalloys: These alloys, such as Inconel, are used in high-temperature applications like jet engine components.

- Composites: Emerging composite materials, including carbon-fiber-reinforced polymers, are being explored for lightweight defense applications.

The choice of material depends on the component’s performance requirements, such as strength, weight, and environmental resistance. CNC spinning’s ability to process these materials with minimal waste enhances its cost-effectiveness and sustainability.

Comparison of CNC Spinning with Other Manufacturing Processes

To understand the advantages of CNC spinning in defense manufacturing, it is useful to compare it with other common processes, such as forging, casting, and additive manufacturing. The following table provides a detailed comparison:

| Process | Precision | Material Waste | Tooling Cost | Production Speed | Complexity of Geometries | Applications in Defense |

|---|---|---|---|---|---|---|

| CNC Spinning | High | Low | Moderate | Moderate to High | High | Missile casings, radar domes, propeller shafts |

| Forging | Moderate | Moderate | High | Moderate | Moderate | Tank components, gun barrels |

| Casting | Low to Moderate | High | High | Low to Moderate | Moderate | Engine blocks, structural frames |

| Additive Manufacturing | High | Low | Low | Low | Very High | Prototypes, complex UAV parts |

Analysis: CNC spinning excels in producing seamless, axially symmetric components with high precision and low material waste, making it ideal for defense applications requiring lightweight, durable parts. Forging and casting, while suitable for high-volume production, involve higher tooling costs and material waste, limiting their flexibility. Additive manufacturing, while capable of producing complex geometries, is slower and less suited for large-scale production of metal components.

Applications of CNC Spinning in Defense Equipment Manufacturing

Missile and Rocket Components

CNC spinning is extensively used to manufacture missile and rocket components, such as nose cones, motor casings, and fuel tanks. These components require seamless construction to ensure structural integrity under high aerodynamic and thermal stresses. For example, the nose cone of a hypersonic missile must withstand temperatures exceeding 2,000°C while maintaining precise aerodynamic contours. CNC spinning’s ability to produce thin-walled, high-strength components from titanium or nickel-based alloys makes it ideal for such applications.

Shear spinning is particularly prevalent in missile manufacturing, as it allows for significant thickness reduction, resulting in lighter components without compromising strength. The process also minimizes welds, which are potential weak points in high-pressure environments. Recent advancements in multi-axis CNC spinning have enabled the production of complex, variable-thickness casings, enhancing missile performance and range.

Aircraft and Helicopter Parts

In aerospace defense, CNC spinning is used to fabricate critical components such as rotor blades, engine cowlings, and structural airframe elements. For instance, the Mi-8 military helicopter, widely used by Russian forces, relies on CNC-spun rotor blades and gearbox components for reliable performance in diverse operational conditions. These components require high precision to ensure aerodynamic efficiency and structural stability, qualities that CNC spinning consistently delivers.

Aluminum and titanium alloys are commonly used in aerospace applications due to their lightweight properties and resistance to corrosion. CNC spinning’s ability to produce seamless, thin-walled structures reduces aircraft weight, improving fuel efficiency and payload capacity. Additionally, the process supports rapid prototyping, allowing manufacturers to test and refine designs for next-generation fighter jets and UAVs.

Naval and Warship Components

CNC spinning plays a critical role in the production of naval defense equipment, particularly for warships and submarines. Components such as propeller shafts, sonar domes, and pressure hull sections benefit from the process’s ability to produce large, seamless parts with high structural integrity. For example, the propulsion system of the Leclerc Main Battle Tank, used by the French Army, incorporates CNC-spun components like turret rings and gun cradles, which require tight tolerances and durability.

The harsh maritime environment, characterized by saltwater corrosion and extreme pressure, necessitates the use of materials like stainless steel and nickel-based alloys. CNC spinning’s compatibility with these materials, combined with its ability to apply surface treatments like nitriding or anodizing, ensures that naval components meet stringent durability requirements. The process also supports the production of customized components for high-mix, low-volume naval applications, aligning with the defense industry’s need for flexibility.

Radar and Electronic Systems

Radar and electronic systems, essential for modern warfare, rely on CNC spinning to produce precision components such as antenna housings, waveguides, and electromagnetic shields. These components require complex geometries and tight tolerances to ensure optimal signal transmission and protection from environmental interference. CNC spinning’s ability to process lightweight materials like aluminum and composites makes it ideal for radar domes, which must balance structural strength with minimal signal attenuation.

The integration of CNC spinning with advanced finishing techniques, such as plating and anodizing, enhances the durability and performance of electronic components in harsh operational environments. For example, radar systems deployed in desert or arctic conditions benefit from CNC-spun housings that resist corrosion and thermal expansion.

Ground Vehicles and Armored Systems

CNC spinning is increasingly used in the production of components for ground-based defense vehicles, including tanks, armored personnel carriers, and artillery systems. Components such as turret rings, gun barrels, and wheel hubs require high strength and precision to withstand the rigors of combat. The Leclerc Main Battle Tank, for instance, incorporates CNC-spun turret rings and gun cradles, which are critical for accurate targeting and durability.

The process’s ability to produce seamless, high-strength components reduces the risk of structural failure under impact or vibration. Additionally, CNC spinning’s compatibility with high-strength steels and titanium alloys ensures that armored vehicle components meet the defense industry’s stringent performance standards.

Industrialization Trends and Innovations

Integration with Industry 4.0

The industrialization of CNC spinning has been profoundly influenced by the advent of Industry 4.0, which emphasizes automation, data exchange, and smart manufacturing. Modern CNC spinning machines are equipped with Internet of Things (IoT) sensors, real-time monitoring systems, and predictive analytics, enabling manufacturers to optimize production processes and reduce downtime. For example, IoT-enabled CNC spinning machines can detect tool wear or material defects in real time, adjusting parameters to maintain quality.

The integration of artificial intelligence (AI) and machine learning (ML) further enhances CNC spinning’s capabilities. AI-driven systems can optimize tool paths, predict material behavior, and automate quality control, reducing human intervention and improving efficiency. In 2018, Siemens and Bonsai Technologies demonstrated the potential of AI in CNC spinning by developing an AI model that auto-calibrated a CNC machine 30 times faster than human operators, highlighting the technology’s transformative impact.

Advancements in Multi-Axis CNC Spinning

The development of multi-axis CNC spinning machines has expanded the range of geometries achievable through the process. Unlike traditional 3-axis machines, which are limited to simple cylindrical shapes, 5-axis and 6-axis machines allow for the production of complex, variable-thickness components with intricate contours. These machines are particularly valuable in defense manufacturing, where components like missile casings and radar domes require non-uniform geometries.

Multi-axis CNC spinning also improves production efficiency by reducing the need for multiple setups and secondary operations. For example, Mazak’s INTEGREX i-500, a multi-tasking CNC spinning machine, integrates turning, milling, and 5-axis machining, enabling the production of finished components in a single setup. This “done-in-one” approach minimizes lead times and enhances cost-effectiveness, aligning with the defense industry’s demand for rapid, high-quality production.

Sustainable CNC Spinning Practices

Sustainability has become a critical consideration in the industrialization of CNC spinning, driven by environmental regulations and the need to reduce manufacturing costs. Recent research highlights several strategies for sustainable CNC spinning, including:

- Optimized Tool Paths: By minimizing unnecessary tool movements, manufacturers can reduce energy consumption and material waste.

- Energy-Efficient Machines: Investing in energy-efficient CNC spinning machines, which use advanced motors and control systems, can significantly lower carbon emissions.

- Virtual Simulation: Virtual simulation tools allow manufacturers to analyze and optimize spinning processes before production, reducing trial-and-error waste.

These practices are particularly relevant in defense manufacturing, where large-scale production of metal components can generate significant environmental impacts. By adopting sustainable CNC spinning techniques, manufacturers can achieve cost savings while meeting regulatory requirements.

Additive Manufacturing Integration

The integration of CNC spinning with additive manufacturing (AM), or 3D printing, represents a frontier in defense equipment manufacturing. Hybrid manufacturing systems, which combine CNC spinning with AM, allow for the production of complex components with enhanced properties. For instance, AM can be used to create a near-net-shape preform, which is then finished using CNC spinning to achieve precise dimensions and surface quality.

This hybrid approach is particularly valuable for producing lightweight, high-strength components for UAVs and hypersonic vehicles, where material efficiency is critical. The U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE), located at the Institute for Advanced Learning and Research (IALR), is exploring such hybrid techniques to develop advanced “recipes” for military parts.

Table: Innovations in CNC Spinning Technology

| Innovation | Description | Impact on Defense Manufacturing |

|---|---|---|

| Industry 4.0 Integration | IoT, AI, and ML for real-time monitoring and process optimization | Improved efficiency, reduced downtime, enhanced quality control |

| Multi-Axis CNC Spinning | 5-axis and 6-axis machines for complex geometries | Increased design flexibility, reduced production time |

| Sustainable Practices | Optimized tool paths, energy-efficient machines, virtual simulation | Lower costs, reduced environmental impact |

| Additive Manufacturing | Hybrid systems combining AM and CNC spinning | Lightweight, high-strength components, rapid prototyping |

Challenges in Industrializing CNC Spinning

Skilled Labor Shortage

One of the most significant challenges facing the industrialization of CNC spinning is the shortage of skilled labor. As the manufacturing workforce ages, with approximately 25% of U.S. manufacturing workers over 55, the industry faces a critical gap in expertise. CNC spinning requires operators with advanced knowledge of programming, material science, and machine maintenance, skills that are in short supply.

To address this challenge, defense manufacturers are investing in training programs and mentorship initiatives. The U.S. Navy’s ATDM program, for example, trains workers in CNC machining and related trades to support the submarine industrial base. Educational institutions, such as Pickens Technical College, are also introducing CNC spinning curricula to prepare the next generation of manufacturing professionals.

High Initial Costs

The high initial cost of CNC spinning equipment, particularly multi-axis and hybrid systems, poses a barrier to widespread adoption. Advanced CNC spinning machines, such as those equipped with 5-axis capabilities or IoT integration, can cost 30% more than traditional models. For small and medium-sized enterprises (SMEs), these costs can be prohibitive, limiting their ability to compete in the defense market.

However, the long-term benefits of CNC spinning, including reduced material waste, lower labor costs, and enhanced production efficiency, often justify the investment. Government subsidies and public-private partnerships, such as those supporting the IALR’s CNC Machining Innovation Lab, can help offset these costs and promote technology adoption.

Cybersecurity Risks

The increased connectivity of CNC spinning machines, driven by Industry 4.0, introduces cybersecurity risks. IoT-enabled systems are vulnerable to data breaches, unauthorized access, and operational disruptions, which could compromise sensitive defense manufacturing processes. For example, a cyberattack on a CNC spinning machine could alter component specifications, leading to defective parts or production delays.

To mitigate these risks, manufacturers are implementing robust cybersecurity measures, including encryption, secure network architectures, and regular software updates. Employee training on recognizing and responding to cyber threats is also critical, particularly in the defense sector, where security is paramount.

Material and Process Limitations

While CNC spinning is highly versatile, it is primarily suited for axially symmetric components, limiting its application to non-symmetrical parts. Additionally, certain high-performance materials, such as advanced ceramics or ultra-high-strength composites, may be difficult to spin due to their brittleness or processing requirements. Ongoing research is addressing these limitations by developing new tooling materials and hybrid processes that combine CNC spinning with other techniques, such as laser cutting or additive manufacturing.

Case Studies in Defense Manufacturing

U.S. Navy’s Additive Manufacturing Center of Excellence

The U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE), housed at the Institute for Advanced Learning and Research (IALR), is a leading example of CNC spinning’s industrialization in defense manufacturing. The AM CoE collaborates with the CNC Machining Innovation Lab to develop advanced manufacturing processes, including hybrid CNC spinning and additive manufacturing, for submarine and naval components. The lab’s state-of-the-art equipment supports testing services, process optimization, and the development of “recipes” for military parts, enhancing the Navy’s supply chain resilience.

Mazak’s INTEGREX i-500 in Missile Production

Mazak’s INTEGREX i-500, a multi-tasking CNC spinning machine, has been adopted by defense contractors to produce missile casings and other critical components. The machine’s ability to integrate turning, milling, and 5-axis machining in a single setup reduces production time and improves precision, making it ideal for high-mix, low-volume defense applications. Its use in missile production demonstrates the potential of multi-axis CNC spinning to meet the defense industry’s evolving needs.

Trumpf’s Laser-Integrated CNC Spinning

Trumpf, a leading CNC machine manufacturer, has developed laser-integrated CNC spinning systems that combine high-speed laser cutting with spinning to produce complex defense components. These systems are used to fabricate radar domes and UAV parts, where precision and surface quality are critical. Trumpf’s technology highlights the role of hybrid processes in advancing CNC spinning’s industrialization.

Future Prospects and Research Directions

Emerging Materials and Processes

The future of CNC spinning in defense manufacturing lies in the development of new materials and processes. Research is underway to explore the spinning of advanced composites, such as carbon-fiber-reinforced polymers, which offer superior strength-to-weight ratios for UAVs and hypersonic vehicles. Additionally, innovations in tooling materials, such as diamond-tipped rollers, are improving the process’s ability to handle ultra-high-strength alloys.

Autonomous Manufacturing Systems

The development of fully autonomous CNC spinning systems, powered by AI and robotics, is a key research direction. These systems could operate with minimal human intervention, enabling “lights-out” manufacturing, where production continues 24/7 without supervision. Such capabilities would be transformative for defense manufacturing, where rapid production scalability is critical during conflicts.

Global Competitiveness and Reshoring

The industrialization of CNC spinning is also shaped by global competitiveness and reshoring trends. As countries like China advance in CNC technology, Western nations are investing in domestic manufacturing to reduce reliance on foreign supply chains. The U.S., for example, saw a record increase in reshoring and foreign direct investment in 2022, driven by the need for secure defense supply chains. CNC spinning’s role in producing high-value, ITAR-compliant components positions it as a strategic asset in these efforts.

Table: Future Research Directions in CNC Spinning

| Research Area | Description | Potential Impact |

|---|---|---|

| Emerging Materials | Spinning of composites and ultra-high-strength alloys | Lightweight, high-performance defense components |

| Autonomous Systems | AI-driven, fully autonomous CNC spinning machines | Increased scalability, reduced labor costs |

| Global Competitiveness | Reshoring and investment in domestic CNC spinning capabilities | Enhanced supply chain security, economic growth |

Conclusion

The industrialization of CNC spinning in defense equipment manufacturing represents a transformative convergence of precision engineering, material science, and digital technology. From its origins in manual metal spinning to its current role as a cornerstone of advanced manufacturing, CNC spinning has evolved to meet the defense industry’s stringent demands for lightweight, high-strength, and complex components. Its applications in missile production, aerospace, naval systems, and radar technology underscore its versatility and strategic importance.

Recent advancements, including Industry 4.0 integration, multi-axis machines, sustainable practices, and hybrid manufacturing, have positioned CNC spinning as a critical enabler of next-generation defense systems. However, challenges such as skilled labor shortages, high initial costs, and cybersecurity risks must be addressed to fully realize its potential. Ongoing research into emerging materials, autonomous systems, and global competitiveness will shape the future of CNC spinning, ensuring its continued relevance in an increasingly complex and dynamic defense landscape.

By providing a comprehensive analysis of CNC spinning’s technical principles, applications, and industrialization trends, this article aims to serve as a definitive resource for researchers, engineers, and policymakers. As defense manufacturing continues to evolve, CNC spinning will remain at the forefront, driving innovation and resilience in the production of critical military equipment.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,