Metal spinning, also known as spin forming or spinning, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Historically significant, the process has evolved significantly with advancements in technology, leading to the development of new techniques and applications in various industries. This article provides a comprehensive exploration of metal spinning, covering its history, principles, techniques, materials, equipment, applications, and recent technological advancements.

Historical Background

Metal spinning has roots that trace back to ancient civilizations, where artisans used simple tools to shape metals into functional objects. Early evidence suggests that metal spinning was practiced in ancient Egypt and China, where metals such as gold, silver, and bronze were commonly used.

Industrial Revolution

The Industrial Revolution in the 18th and 19th centuries marked a significant turning point for metal spinning. The advent of the lathe machine and steam power enabled more precise and efficient production of metal components. Metal spinning became an essential process in manufacturing items such as lamps, cookware, and musical instruments.

20th Century Developments

The 20th century saw further advancements in metal spinning technology, particularly with the introduction of motorized lathes and automated systems. These innovations allowed for greater precision, consistency, and productivity, making metal spinning a viable option for mass production in various industries, including aerospace, automotive, and electronics.

Principles of Metal Spinning

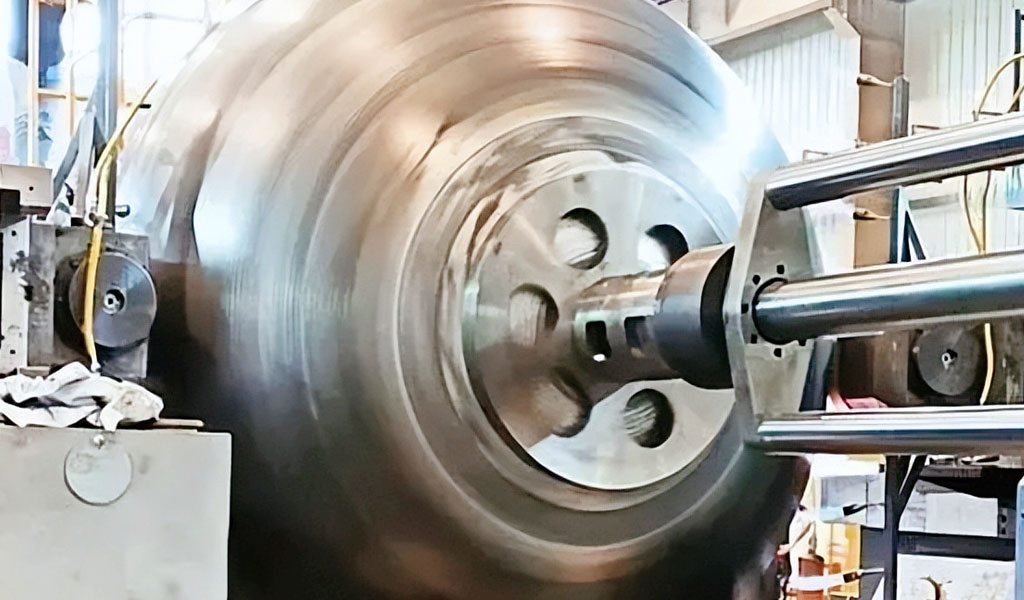

Metal spinning involves clamping a metal blank against a mandrel, which is a form that shapes the metal. The blank and mandrel are then rotated together at high speed. A roller or forming tool is applied to the rotating blank, gradually shaping it to conform to the mandrel. The process can produce complex shapes with a high degree of precision and smooth finishes.

Types of Metal Spinning

There are several variations of metal spinning, each suited to different applications and material types:

- Conventional Spinning: This involves simple shapes and is the most basic form of metal spinning, often used for producing cylindrical or conical parts.

- Shear Spinning: Also known as flow turning, this technique involves thinning the material as it is spun, allowing for the production of stronger, lightweight components.

- Tube Spinning: This method is used for shaping tubes and involves the axial stretching and thinning of the material.

- Hot Spinning: In this process, the metal is heated to make it more malleable, allowing for the forming of harder metals or more complex shapes.

Materials

Metal spinning can be performed on a wide range of metals, each offering different properties and advantages:

- Aluminum: Lightweight and corrosion-resistant, aluminum is widely used in aerospace and automotive industries.

- Steel: Both carbon and stainless steel are used for their strength and durability, making them suitable for heavy-duty applications.

- Copper: Known for its excellent conductivity, copper is often used in electrical and plumbing components.

- Brass: This alloy of copper and zinc offers good machinability and corrosion resistance, commonly used in decorative items and musical instruments.

- Titanium: Lightweight yet strong, titanium is ideal for aerospace and medical applications, though it requires special techniques due to its high strength-to-weight ratio.

Equipment and Tools

The central piece of equipment in metal spinning is the lathe, which comes in various types and sizes:

- Manual Lathes: Operated by skilled craftsmen, manual lathes are suitable for small production runs and prototyping.

- CNC Lathes: Computer Numerical Control (CNC) lathes offer high precision and repeatability, making them ideal for large-scale production.

- Turret Lathes: These lathes are equipped with multiple tools, allowing for more complex operations without the need to change tools frequently.

Mandrels

Mandrels are critical components in metal spinning, as they define the shape of the final product. Mandrels can be made from various materials, including wood, steel, and aluminum, depending on the application and production volume.

Forming Tools

Forming tools, such as rollers and spoons, are used to apply pressure to the spinning metal. These tools are typically made from hardened steel or other durable materials to withstand the forces involved in the process.

Techniques and Processes

The first step in metal spinning involves selecting the appropriate blank and preparing it for the process. This includes cutting the blank to the desired size and thickness, and sometimes pre-heating the material if hot spinning is required.

Clamping and Spinning

The blank is then clamped onto the mandrel, and the lathe is set to the required speed. The spinning process begins with the forming tool gradually applying pressure to shape the metal against the mandrel. This process requires careful control to avoid defects such as wrinkling or tearing.

Secondary Operations

After the initial spinning, secondary operations may be performed to refine the shape or add features such as holes or flanges. These operations can include trimming, beading, and polishing.

Applications

Aerospace

In the aerospace industry, metal spinning is used to produce lightweight yet strong components such as nose cones, engine parts, and satellite dishes. The ability to form complex shapes with high precision makes metal spinning ideal for aerospace applications.

Automotive

Metal spinning is widely used in the automotive industry to manufacture components such as wheels, exhaust systems, and fuel tanks. The process allows for the production of durable, high-performance parts that meet the stringent requirements of the automotive sector.

Medical Devices

The medical industry relies on metal spinning for producing components such as surgical instruments, prosthetics, and medical implants. The precision and cleanliness of the process are critical for ensuring the safety and effectiveness of medical devices.

Consumer Goods

Metal spinning is also used to produce a wide range of consumer goods, including cookware, lighting fixtures, and musical instruments. The process allows for the creation of aesthetically pleasing and functional products.

Recent Technological Advancements

The integration of CNC technology has revolutionized metal spinning, allowing for greater automation, precision, and repeatability. CNC lathes can perform complex operations with minimal human intervention, increasing efficiency and reducing costs.

Advanced Materials

The development of new materials, such as high-strength alloys and composites, has expanded the applications of metal spinning. These materials offer improved performance characteristics, such as higher strength-to-weight ratios and better corrosion resistance.

Simulation and Modeling

Advancements in computer-aided design (CAD) and simulation software have improved the ability to design and optimize metal spinning processes. These tools allow engineers to predict the behavior of materials and optimize process parameters, reducing the need for costly trial and error.

Additive Manufacturing

The combination of metal spinning with additive manufacturing techniques has opened new possibilities for creating complex, multi-material components. This hybrid approach leverages the strengths of both processes, enabling the production of parts with enhanced functionality and performance.

Environmental Considerations

Metal spinning is known for its high material efficiency, as the process generates minimal waste compared to other forming techniques. The ability to produce near-net shape parts reduces the need for secondary machining operations, further minimizing material waste.

Energy Consumption

Modern metal spinning equipment is designed to be energy-efficient, with advancements in motor technology and automation reducing overall energy consumption. Additionally, the use of high-speed forming techniques can shorten production cycles, leading to further energy savings.

Recycling

The cnc metal spinning industry is increasingly focused on sustainability, with many manufacturers implementing recycling programs to reclaim and reuse scrap material. This not only reduces waste but also lowers the environmental impact of metal production.

Challenges and Future Directions

Technical Challenges

While metal spinning offers many advantages, it also presents certain technical challenges. These include controlling material deformation to prevent defects, managing the heat generated during the process, and ensuring the consistency of complex shapes.

Skill Development

Despite advancements in automation, skilled operators are still essential for successful metal spinning. Training and skill development programs are crucial for maintaining a workforce capable of operating advanced equipment and performing intricate operations.

Future Trends

The future of metal spinning is likely to be shaped by ongoing technological advancements and industry trends. Key areas of focus include further integration of digital technologies, development of new materials and processes, and continued efforts to improve sustainability and efficiency.

Digitalization and Industry 4.0

The adoption of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is expected to enhance the capabilities of metal spinning. These technologies can provide real-time monitoring and control of the spinning process, enabling predictive maintenance and optimization of production parameters.

New Material Innovations

Research into new materials and alloys is likely to yield innovative solutions that enhance the performance and capabilities of metal spinning. For example, the development of materials with improved formability and strength could expand the range of applications for the process.

Sustainable Practices

As environmental concerns continue to grow, the metal spinning industry is expected to prioritize sustainability. This includes the development of eco-friendly materials, energy-efficient processes, and recycling initiatives to minimize the environmental impact of metal spinning.

Conclusion

Metal spinning is a versatile and evolving metalworking process with a rich history and a promising future. From its early beginnings to its current applications in high-tech industries, metal spinning has demonstrated its value in producing complex, high-quality components. Advances in technology, materials, and sustainability practices are poised to further enhance the capabilities and applications of metal spinning, ensuring its continued relevance in the manufacturing landscape.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,