Recently, during the 2021 annual evaluation event for outstanding achievements and best practice cases in the construction of Digital Xi’an organized by the Xi’an Municipal Committee’s Cyberspace Administration, the Xi’an Aerospace Big Data Center at the Xi’an Aerospace Base was awarded for “Industrial Digitalization” as an outstanding achievement and best practice case. This recognition highlights the dynamic development of the digital economy at the base and propels digital aerospace construction to new heights.

The Xi’an Aerospace Big Data Center is the first aerospace industry big data center in the country and serves as a core platform for integrated innovation and entrepreneurship for large, medium, and small enterprises in the Xi’an Aerospace Base. It features ten major functions, including collaborative manufacturing, supply-demand matching, financial services, industrial applications, and cloud computing, offering over 50 financial loan products and more than 20 industrial application products. Currently, the center hosts over 2,000 enterprises on its cloud platform, records nearly 600 pieces of scientific and technological achievement information, nearly 200 pieces of information on high-end scientific and technological talent and skilled workers, and has uploaded more than 1,000 pieces of production capacity equipment information. It has facilitated loans exceeding 200 million yuan and is gradually developing into a core platform for integrated development in China’s aerospace industry.

Precise Services to Meet Business Needs

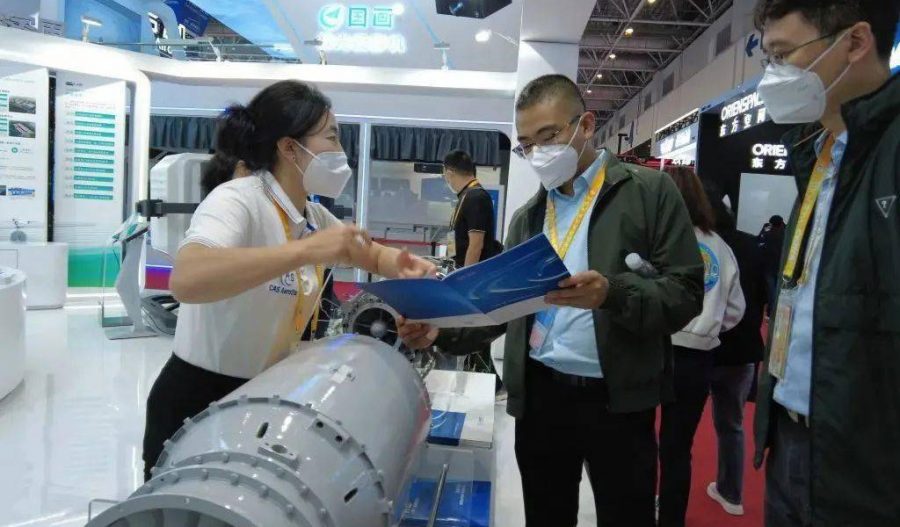

To meet the strong demand for industrial integration in the region, open up the aerospace product supply chain, and enhance aerospace product processing capabilities, the Xi’an Aerospace Big Data Center’s cloud platform uses a portal website, mobile applications, and WeChat clients as interactive interfaces. It gathers aerospace enterprises of all sizes, research institutes, universities, and service organizations to provide comprehensive online services for businesses, helping small and medium-sized aerospace enterprises improve their information management capabilities and complete digital transformation and upgrades.

The Xi’an Aerospace Big Data Center leverages its role in information sharing and resource connectivity by providing procurement and supply-demand information on aerospace components, new aerospace materials, and major aerospace equipment such as large aerospace forging hydraulic presses and large aerospace spinning machines. This helps companies seize new development opportunities, effectively reduce equipment costs, and achieve integrated development of market, production capacity, and equipment in the aerospace industry.

In addition, to better serve business development, the Xi’an Aerospace Big Data Center offers a range of services including an industrial application supermarket, intellectual property, talent services, and corporate profiles. By building bridges between professional talent and specialized companies, it promotes the transfer and transformation of scientific and technological achievements from government, industry, academia, and research to provide fresh impetus and quality services for business growth.

Pooling Resources to Support Business Development

In recent years, the Xi’an Aerospace Big Data Center has focused on “aerospace industry + industrial internet” as a breakthrough point, following the “1+N” innovative development approach to build a new “online aerospace base.” Here, “1” refers to the establishment of an industrial cloud platform for aerospace enterprises of all sizes, providing industry support and supply-demand matching services for the upstream and downstream of the supply chain. This promotes the collaborative development of cloud-based enterprises and achieves resource integration between online and offline, constructing a comprehensive industrial support platform. “N” refers to multiple specialized sub-platforms centered around the core platform, including industry collaboration services, digital services, financial services, and professional talent training services.

Currently, the Xi’an Aerospace Big Data Center has established cooperation with well-known industrial service providers such as Dassault, Huatiang, and Kingdee, and successfully introduced financial institutions such as Bank of China, China Construction Bank, and new internet banks like WeBank. More enterprises, universities, research institutes, and startup teams are joining the cloud platform, pooling key elements like equipment, production capacity, technological achievements, and professional talent. The center is gradually evolving into a national industry service platform, providing significant support for the development of real enterprises.

Meanwhile, the Xi’an Aerospace Big Data Center promotes the application of industrial internet products such as industrial design and testing software, smart manufacturing systems, and supply chain management systems. It continues to provide solutions for the integration of industrialization and informatization for aerospace manufacturing companies, exploring application scenarios for aerospace intelligent manufacturing. At Xi’an Yulieke Industrial Co., Ltd., a company within the zone, the multi-layered information platform meticulously constructed by the center covers various modules including production operations, research and development, and engineering, continuously optimizing the company’s overall structure and business processes, effectively enhancing its core competitiveness.

Financial Support to Stimulate Business Vitality

Based on data and focusing on services, the Xi’an Aerospace Big Data Center emphasizes nurturing the industrial internet ecosystem, deepening the digital transformation and upgrade of industries, and utilizing information, technology, and financial means to pool bank-specific credit products and provide one-stop financing services with multi-scenario support and full-process coverage.

The platform has specifically launched a “Financial Services” section, where pilot banks and guarantee institutions have put their “Aerospace Support Loan” and “Aerospace Ticket Easy Loan” credit products on the cloud platform. Enterprises can access information about these “government-bank-guarantee” credit products through the platform and apply online, enabling self-application, self-disbursement, revolving use, and flexible repayment. This simplifies procedures, streamlines processes, and quickly addresses issues related to large-scale and difficult financing for businesses.

Currently, the Xi’an Aerospace Big Data Center has successfully connected with 17 banks including Bank of China, China Construction Bank, Postal Savings Bank, WeBank, and Xi’an Bank, offering 53 financial products. It has hosted six bank-enterprise matchmaking events, inviting over 300 companies and facilitating loans exceeding 200 million yuan, effectively invigorating the new vitality of the aerospace real economy.

In the future, the Xi’an Aerospace Big Data Center will continue to deepen its work in areas such as industrial chain collaboration, financial services, digital services, and talent cultivation. It will cover the entire business process of research and development, production, procurement, sales, and services, and fully build an “online aerospace base” with complete IT infrastructure and service capabilities. The goal is to achieve “digital industrialization and industrial digitalization” development, create a demonstration zone for the digital transformation of the aerospace industry, and comprehensively advance the collaborative integration of the aerospace industry and enterprise supply chains as well as the digital and intelligent upgrade of production and manufacturing.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,