Corrosion-resistant alloy (CRA) spinning cylinders are critical components in marine engineering, designed to withstand the harsh environmental conditions of seawater, including high salinity, fluctuating temperatures, and mechanical stresses. These cylinders, often used in applications such as hydraulic riser tensioners, piston rods, and structural supports for offshore platforms, require exceptional forming performance during manufacturing and robust service performance during their operational life. The forming process, typically involving spinning techniques, must produce components with precise geometries, high strength, and resistance to defects. Service performance, on the other hand, is governed by the alloy’s ability to resist corrosion, fatigue, and wear in marine environments, where chloride-induced pitting, crevice corrosion, and microbiologically influenced corrosion (MIC) pose significant challenges.

This article comprehensively reviews the research on the forming performance and service performance evolution of CRA spinning cylinders, focusing on their material selection, manufacturing processes, microstructural evolution, corrosion behavior, and long-term durability. The discussion integrates findings from recent studies, emphasizing the role of alloy composition, processing techniques, and environmental factors. Detailed tables are provided to compare key properties and performance metrics, offering a scientific foundation for understanding and optimizing these critical marine engineering components.

Material Selection for Corrosion-Resistant Alloy Spinning Cylinders

Overview of Corrosion-Resistant Alloys

Corrosion-resistant alloys used in marine engineering are selected based on their ability to form protective oxide layers, resist localized corrosion, and maintain mechanical integrity under cyclic loading. Common alloys include stainless steels (e.g., duplex and super-austenitic grades), nickel-based alloys (e.g., Inconel 625, Hastelloy C-276), titanium alloys (e.g., Ti6Al4V), and copper-nickel alloys (e.g., 90-10 and 70-30 cupronickel). Each alloy offers unique advantages, with trade-offs in cost, formability, and corrosion resistance.

Stainless steels, particularly duplex grades like UNS S31803 and super-austenitic grades like UNS N08367, are favored for their balance of strength and corrosion resistance. Nickel-based alloys excel in extreme environments due to their stable passive films, while titanium alloys offer lightweight properties and excellent resistance to chloride-induced corrosion. Copper-nickel alloys are valued for their antifouling properties, reducing biofouling in marine applications. The choice of alloy depends on the specific requirements of the spinning cylinder, including operating environment, mechanical loads, and expected service life.

Alloy Composition and Corrosion Resistance

The corrosion resistance of CRAs is closely tied to their chemical composition. For instance, the addition of chromium (Cr) enhances the formation of stable oxide layers, while molybdenum (Mo) improves resistance to pitting and crevice corrosion. Nitrogen (N) in austenitic stainless steels increases the stability of passive films, as demonstrated in high-nitrogen austenitic stainless steels (HNSS), which exhibit a larger proportion of stable oxides. Similarly, the incorporation of aluminum (Al) and manganese (Mn) in alloys like Al-Mn-Cr-Zr-based compositions promotes the formation of resistant passive films, extending the passivity region compared to traditional AlSi10Mg alloys.

Table 1 compares the chemical compositions of selected CRAs used in spinning cylinders, highlighting key elements influencing corrosion resistance.

| Alloy | Cr (wt.%) | Ni (wt.%) | Mo (wt.%) | Al (wt.%) | Mn (wt.%) | Ti (wt.%) | Cu (wt.%) | N (wt.%) | Other Elements |

|---|---|---|---|---|---|---|---|---|---|

| UNS S31803 (Duplex SS) | 21.0–23.0 | 4.5–6.5 | 2.5–3.5 | – | 2.0 max | – | – | 0.08–0.20 | Fe (balance) |

| UNS N08367 (Super-Austenitic SS) | 20.0–22.0 | 23.5–25.5 | 6.0–7.0 | – | 2.0 max | – | – | 0.18–0.25 | Fe (balance) |

| Inconel 625 | 20.0–23.0 | 58.0 min | 8.0–10.0 | 0.4 max | 0.5 max | 0.4 max | – | – | Nb (3.15–4.15) |

| Ti6Al4V | – | – | – | 5.5–6.75 | – | 88.0–91.0 | – | – | V (3.5–4.5) |

| 90-10 Cu-Ni | – | 9.0–11.0 | – | – | 1.0 max | – | 86.0–89.0 | – | Fe (1.0–1.8) |

| Al-Mn-Cr-Zr | 0.5–1.0 | – | – | 95.0–97.0 | 1.0–2.0 | – | – | – | Zr (0.1–0.5) |

Mechanical Properties and Formability

Formability is a critical factor in the spinning process, as it determines the alloy’s ability to undergo plastic deformation without cracking or developing defects. High-strength alloys like Ti6Al4V and Inconel 625 exhibit excellent mechanical properties but pose challenges during forming due to their high yield strength and low ductility at room temperature. Duplex stainless steels offer a balance of strength and ductility, making them suitable for complex geometries. Aluminum alloys, such as 6061-T6, are highly formable but may require surface treatments to enhance corrosion resistance in marine environments.

Table 2 summarizes the mechanical properties of CRAs relevant to spinning cylinder applications.

| Alloy | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| UNS S31803 | 450–550 | 620–830 | 25–30 | 270–300 |

| UNS N08367 | 310–350 | 690–790 | 30–40 | 200–250 |

| Inconel 625 | 414–517 | 827–965 | 30–50 | 200–300 |

| Ti6Al4V | 880–950 | 950–1100 | 10–14 | 320–380 |

| 90-10 Cu-Ni | 110–150 | 310–350 | 40–50 | 80–120 |

| Al-Mn-Cr-Zr | 200–250 | 300–350 | 15–20 | 100–150 |

Spinning Process for Corrosion-Resistant Alloy Cylinders

Fundamentals of Spinning Technology

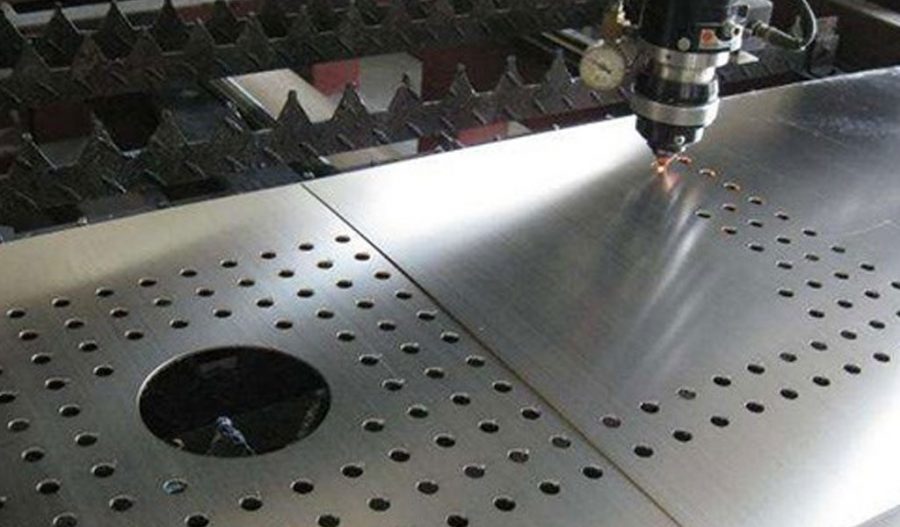

Spinning is a metalworking process that involves rotating a metal blank or tube on a lathe while applying localized pressure with a roller to shape it into a cylindrical component. For CRAs, spinning is preferred due to its ability to produce seamless, high-precision cylinders with minimal material waste. The process can be hot or cold, depending on the alloy’s properties and desired microstructure. Hot spinning is used for high-strength alloys like Inconel 625 to reduce forming forces, while cold spinning is suitable for ductile alloys like copper-nickel.

The spinning process influences the microstructure, residual stresses, and surface quality of the cylinder, all of which affect its service performance. Key parameters include spinning speed, roller pressure, feed rate, and temperature control. Advanced techniques, such as CNC-controlled spinning and flow-forming, enhance precision and allow for complex geometries.

Challenges in Spinning CRAs

Spinning CRAs presents several challenges, including work hardening, springback, and surface defects. High-strength alloys like Ti6Al4V exhibit significant work hardening, increasing the forming forces required and risking tool wear. Springback, caused by elastic recovery after deformation, can lead to dimensional inaccuracies. Surface defects, such as scratches or microcracks, may act as initiation sites for corrosion in marine environments.

To mitigate these challenges, researchers have explored optimized spinning parameters and hybrid processes. For example, preheating the workpiece reduces forming forces for nickel-based alloys, while multi-pass spinning minimizes residual stresses. Surface treatments, such as electropolishing or plasma ion nitriding, enhance the corrosion resistance of spun surfaces.

Microstructural Evolution During Spinning

The spinning process induces significant microstructural changes, including grain refinement, phase transformations, and precipitate formation. For duplex stainless steels, spinning can enhance the ferrite-austenite balance, improving mechanical properties. In aluminum alloys, such as Al-Mn-Cr-Zr, rapid cooling during spinning results in finer grain sizes, enhancing corrosion resistance. However, excessive deformation may introduce dislocations or microvoids, which can compromise long-term durability.

Table 3 compares the microstructural characteristics of CRAs before and after spinning.

| Alloy | Pre-Spinning Microstructure | Post-Spinning Microstructure | Key Changes |

|---|---|---|---|

| UNS S31803 | Ferrite-austenite dual phase | Refined ferrite-austenite, increased dislocation density | Grain refinement, enhanced phase balance |

| UNS N08367 | Austenitic with fine grains | Elongated grains, increased hardness | Work hardening, minor grain elongation |

| Inconel 625 | Austenitic with carbides | Fine recrystallized grains, reduced carbides | Dynamic recrystallization, improved homogeneity |

| Ti6Al4V | Alpha-beta phase | Elongated alpha grains, refined beta | Increased dislocation density, phase distortion |

| 90-10 Cu-Ni | Single-phase FCC | Slightly refined grains, surface hardening | Minimal phase change, surface densification |

| Al-Mn-Cr-Zr | Coarse Al matrix with precipitates | Finer grains, dispersed precipitates | Enhanced precipitate distribution, reduced grain size |

Corrosion Mechanisms in Marine Environments

Types of Corrosion in Marine Applications

Marine environments are among the most aggressive for metallic components, with corrosion driven by chloride ions, oxygen, and biological activity. The primary corrosion mechanisms affecting CRA spinning cylinders include:

- Pitting Corrosion: Localized attack forming small pits, often initiated at surface defects or inclusions. Pitting is prevalent in chloride-rich environments and is a major concern for stainless steels and aluminum alloys.

- Crevice Corrosion: Occurs in confined spaces, such as joints or under deposits, where oxygen depletion leads to acidic conditions. Super-austenitic stainless steels with high Mo content (e.g., UNS N08367) show improved resistance.

- Intergranular Corrosion (IGC): Corrosion along grain boundaries, often due to sensitization or precipitate formation. This is a significant issue for aluminum alloys like 7075 in marine atmospheres.

- Microbiologically Influenced Corrosion (MIC): Driven by microorganisms like Bacillus cereus, which accelerate corrosion through biofilm formation. Copper-nickel alloys are less susceptible due to their antifouling properties.

- Corrosion Fatigue: The synergistic effect of cyclic loading and corrosion, leading to crack initiation and propagation. This is critical for spinning cylinders under dynamic loads in marine environments.

Electrochemical Behavior and Passive Film Formation

The corrosion resistance of CRAs relies on the formation of a stable passive film, typically composed of oxides or hydroxides. For stainless steels, the passive film consists of Cr2O3 and Fe2O3, with Mo enhancing its stability. In aluminum alloys, Al2O3 and Al(OH)3 films form, but their integrity depends on environmental conditions. Nickel-based alloys like Inconel 625 form NiO and Cr2O3 layers, which are highly resistant to breakdown in seawater.

Electrochemical tests, such as potentiodynamic polarization and electrochemical impedance spectroscopy (EIS), are used to evaluate corrosion behavior. For example, Al-Mn-Cr-Zr alloys exhibit lower corrosion current densities (icorr) and higher impedance in NaCl solutions compared to AlSi10Mg, indicating superior corrosion resistance.

Table 4 presents corrosion performance metrics for CRAs in simulated marine environments.

| Alloy | Corrosion Potential (Ecorr, mV vs. SCE) | Corrosion Current Density (icorr, µA/cm²) | Pitting Potential (Epitt, mV vs. SCE) | Corrosion Rate (mpy) |

|---|---|---|---|---|

| UNS S31803 | -250 to -200 | 0.5–1.0 | 800–1000 | 0.01–0.05 |

| UNS N08367 | -200 to -150 | 0.2–0.5 | 1000–1200 | 0.005–0.02 |

| Inconel 625 | -150 to -100 | 0.1–0.3 | 1200–1400 | 0.002–0.01 |

| Ti6Al4V | -300 to -250 | 0.3–0.8 | 900–1100 | 0.01–0.03 |

| 90-10 Cu-Ni | -200 to -150 | 1.0–2.0 | 600–800 | 0.05–0.1 |

| Al-Mn-Cr-Zr | -600 to -550 | 2.0–5.0 | 400–600 | 0.1–0.2 |

Service Performance Evolution

Long-Term Durability in Marine Environments

The service performance of CRA spinning cylinders evolves over time due to environmental exposure, mechanical loading, and microstructural changes. Long-term durability is influenced by the interplay of corrosion, fatigue, and wear. For example, 7075 aluminum alloys exposed to marine atmospheres exhibit pitting and intergranular corrosion after one month, with IGC depth increasing from 114 μm to 190 μm over 12 months. In contrast, copper-nickel alloys maintain stable performance due to their antifouling properties, though sulfides in polluted waters can interfere with film formation.

Corrosion Fatigue and Crack Propagation

Corrosion fatigue is a critical concern for spinning cylinders under cyclic loading in marine environments. Pitting acts as a stress concentrator, initiating cracks that propagate under fatigue loads. The stress intensity factor (ΔK) at pit roots increases with pit depth, accelerating crack growth. Duplex stainless steels and nickel-based alloys exhibit superior resistance to corrosion fatigue due to their high strength and stable passive films.

Surface Treatments and Coatings

Surface treatments, such as plasma ion nitriding, electropolishing, and coatings, enhance the service life of CRA cylinders. For instance, plasma ion nitriding of UNS N08367 improves electrochemical resistance by forming a nitrogen-rich surface layer. Coatings like Al2O3-MoS2 on aluminum alloys reduce corrosion rates by providing a barrier against chloride ions. Table 5 compares the effectiveness of surface treatments.

| Alloy | Surface Treatment | Corrosion Rate Reduction (%) | Fatigue Life Improvement (%) | Key Benefits |

|---|---|---|---|---|

| UNS S31803 | Plasma Ion Nitriding | 50–70 | 20–30 | Enhanced surface hardness, reduced pitting |

| UNS N08367 | Electropolishing | 60–80 | 15–25 | Smoother surface, improved passive film stability |

| Inconel 625 | PVD CrN Coating | 70–90 | 25–40 | High corrosion resistance, wear protection |

| Ti6Al4V | ZnAl-LDH Coating | 80–95 | 10–20 | Superior corrosion protection, biocompatibility |

| 90-10 Cu-Ni | Ferrous Sulfate Treatment | 40–60 | 5–15 | Enhanced antifouling, reduced MIC |

| Al-Mn-Cr-Zr | Al2O3-MoS2 Coating | 60–80 | 15–25 | Barrier protection, reduced wear |

Advanced Modeling and Machine Learning in Performance Prediction

Machine Learning for Corrosion Prediction

Machine learning (ML) has emerged as a powerful tool for predicting the corrosion behavior of CRAs. ML models, such as random forest (RF) and deep neural networks, use datasets of alloy compositions, environmental conditions, and corrosion metrics (e.g., icorr, Ecorr) to predict performance. For high-entropy alloys (HEAs), ML has been used to optimize compositions for corrosion resistance, reducing reliance on trial-and-error methods. In marine corrosion studies, RF models with charge correction achieved high accuracy (R² = 0.940) for predicting long-term corrosion rates.

Finite Element Analysis of Spinning and Service Performance

Finite element analysis (FEA) is used to model the stress distribution, deformation, and crack propagation in spinning cylinders. FEA simulations of the spinning process help optimize parameters to minimize residual stresses, while service performance models predict fatigue life and corrosion damage. For example, FEA of Q690 high-strength steel welds in simulated marine environments revealed that pearlite morphology control enhances corrosion resistance.

Future Directions and Research Gaps

Emerging Alloys and Manufacturing Techniques

The development of new CRAs, such as high-entropy alloys and advanced aluminum alloys, offers opportunities to improve forming and service performance. Additive manufacturing (AM) is gaining attention for producing complex cylinder geometries, but its impact on corrosion resistance requires further study. Hybrid manufacturing processes, combining spinning with AM, could enable tailored microstructures for specific marine applications.

Environmental and Regulatory Considerations

The push for sustainable materials has led to increased scrutiny of CRAs with toxic elements, such as Cr(VI) in stainless steels. Environmentally friendly coatings and surface treatments, like ZnAl-LDH films, are being explored to reduce ecological impacts. Regulatory frameworks, such as the Paris Agreement, emphasize the need for corrosion-resistant materials in low-carbon energy systems, driving research into alloys for offshore wind and carbon capture applications.

Research Gaps

Despite significant progress, several research gaps remain:

- Long-Term Corrosion Fatigue Data: Limited studies address the combined effects of corrosion and fatigue over extended periods in real marine environments.

- Microstructural Effects of Spinning: The impact of spinning-induced microstructural changes on long-term corrosion resistance is not fully understood.

- Scalability of Surface Treatments: The application of advanced coatings like LDH on large-scale cylinders requires further optimization.

- Machine Learning Integration: ML models need larger, standardized datasets to improve prediction accuracy for complex marine environments.

Conclusion

The research on forming performance and service performance evolution of corrosion-resistant alloy spinning cylinders for marine engineering highlights the critical interplay between material selection, manufacturing processes, and environmental durability. Alloys like duplex stainless steels, nickel-based alloys, and titanium alloys offer robust solutions, but their performance depends on optimized spinning techniques and surface treatments. Advanced modeling, including machine learning and finite element analysis, is transforming the design and prediction of cylinder performance. Future research should focus on addressing gaps in long-term durability, microstructural optimization, and sustainable material solutions to meet the demands of marine engineering.

This comprehensive review, supported by detailed tables, provides a scientific foundation for engineers and researchers to advance the development of CRA spinning cylinders, ensuring reliability and longevity in the harshest marine environments.

Maximize Tooling and CNC Metal Spinning Capabilities.

At BE-CU China Metal Spinning company, we make the most of our equipment while monitoring signs of excess wear and stress. In addition, we look into newer, modern equipment and invest in those that can support or increase our manufacturing capabilities. Our team is very mindful of our machines and tools, so we also routinely maintain them to ensure they don’t negatively impact your part’s quality and productivity.

Talk to us today about making a rapid prototype with our CNC metal spinning service. Get a direct quote by chatting with us here or request a free project review.

BE-CU China CNC Metal Spinning service include : CNC Metal Spinning,Metal Spinning Die,Laser Cutting, Tank Heads Spinning,Metal Hemispheres Spinning,Metal Cones Spinning,Metal Dish-Shaped Spinning,Metal Trumpet Spinning,Metal Venturi Spinning,Aluminum Spinning Products,Stainless Steel Spinning Products,Copper Spinning Products,Brass Spinning Products,Steel Spinning Product,Metal Spinnin LED Reflector,Metal Spinning Pressure Vessel,