The origins of metal spinning can be traced back to ancient civilizations, where artisans used rudimentary tools to shape metals into vessels and decorative items. However, its adoption in marine engineering began in earnest during the Industrial Revolution, when advancements in machinery enabled precise control over rotational speeds and forming pressures. By the late 19th century, spinning was employed to fabricate components for steamships, such as boiler fittings and propeller hubs, which required uniform thickness and structural integrity. In the 20th century, the advent of computer numerical control (CNC) spinning machines revolutionized the process, allowing for greater precision and repeatability. This was particularly significant in marine engineering, where components like propeller blades, sonar domes, and pressure hulls demanded exacting tolerances Read more

Application of Spinning in Rail Transportation

Spinning, a metalworking process involving the deformation of a rotating metal workpiece to form axially symmetric components, has found significant applications in rail transportation. This technique, rooted in ancient craftsmanship but refined through modern engineering, enables the production of high-strength, lightweight, and precise components critical to the performance, safety, and efficiency of rail systems. From the manufacturing of wheels and axles to the fabrication of structural components and specialized parts, spinning has become integral to the rail industry. This article explores the historical evolution, technical principles, specific applications, material considerations, manufacturing advancements, economic impacts, and future prospects of spinning in rail transportation, providing a comprehensive overview supported by comparative data. Historical Context of Spinning in Rail Transportation The origins of Read more

Technology of Spinning in the Manufacture of Metal Bellows

Metal bellows are precision-engineered, flexible components designed to accommodate axial, lateral, and angular movements while maintaining a hermetic seal. These versatile structures are critical in industries such as aerospace, semiconductor manufacturing, medical devices, and oil and gas, where they serve as actuators, seals, expansion joints, and sensors. The manufacturing of metal bellows involves several techniques, including hydroforming, edge-welding, and electroforming, but one of the foundational processes for creating seamless bellows is metal spinning, also known as spin forming. This article explores the technology of spinning in the manufacture of metal bellows, delving into its historical evolution, technical principles, material considerations, process variations, and modern advancements. Detailed comparisons of spinning with other bellows manufacturing methods are provided to highlight its unique Read more

The Role of Spinning in the Manufacturing of Drone Parts

Spinning, a metalworking process that involves rotating a metal disc or tube at high speed while applying localized pressure to shape it, plays a pivotal role in the manufacturing of drone components. Known as metal spinning or spin forming, this technique has been adapted to meet the demands of modern aerospace applications, particularly in the burgeoning field of unmanned aerial vehicles (UAVs), commonly referred to as drones. The process is valued for its ability to produce lightweight, high-strength, and seamless parts, which are critical for the performance, efficiency, and reliability of drones used in commercial, military, and recreational applications. This article explores the historical context, technical principles, material considerations, applications, advantages, challenges, and future trends of spinning in drone part Read more

Comprehensive Overview of Hydroforming Technology

Hydroforming is a specialized manufacturing process used to shape ductile metals, such as aluminum, brass, copper, steel, and stainless steel, into structurally robust, lightweight components. This technique employs high-pressure hydraulic fluid to press metal into a die, enabling the creation of complex geometries that are often unattainable through conventional metal-forming methods like stamping or forging. Hydroforming is widely utilized across industries, including automotive, aerospace, plumbing, and consumer goods, due to its ability to produce parts with high strength-to-weight ratios, minimal material waste, and enhanced structural integrity. This article provides an in-depth exploration of hydroforming, covering its principles, processes, equipment, materials, applications, advantages, limitations, and future trends, with a focus on scientific rigor and technical detail. 1. Introduction to Hydroforming 1.1 Read more

Which One Withstands Constant Sunlight Exposure?

Constant sunlight exposure poses significant challenges to materials, surfaces, and living organisms due to the intense ultraviolet (UV) radiation, thermal energy, and photochemical reactions it induces. Understanding which materials and organisms can withstand prolonged exposure to sunlight is critical for applications in architecture, agriculture, aerospace, and environmental science. This article explores the resilience of various materials (e.g., metals, polymers, coatings, and textiles) and biological entities (e.g., plants, microorganisms, and human skin) under constant sunlight exposure. It examines the mechanisms of degradation, protective strategies, and comparative performance through empirical data and theoretical frameworks. Introduction Sunlight, a primary source of energy for Earth’s ecosystems, consists of electromagnetic radiation spanning ultraviolet (UV, 100–400 nm), visible (400–700 nm), and infrared (IR, >700 nm) wavelengths. Read more

Safety Under Pressure: Pressure Vessel Shape Matters

Pressure vessels are critical components in numerous industrial, commercial, and scientific applications, designed to contain gases or liquids at pressures substantially different from the ambient environment. These vessels are integral to processes in industries such as petrochemical, pharmaceutical, nuclear, and aerospace engineering. The safety, efficiency, and longevity of pressure vessels are heavily influenced by their geometric design, material selection, and operational conditions. Among these factors, the shape of a pressure vessel plays a pivotal role in determining its ability to withstand internal pressures, resist external forces, and ensure operational safety. This article explores the significance of pressure vessel shape in ensuring safety under pressure, delving into the engineering principles, material considerations, and practical applications that govern their design. Through a Read more

Difficulties in Metal Spinning Special Alloys

Metal spinning, also known as spin forming or centrifugal forming, is a metalworking process that involves rotating a metal disc or tube at high speeds while applying localized pressure to shape it into axially symmetric components. This technique is valued for its ability to produce seamless, high-strength parts with minimal material waste, making it a preferred method in industries such as aerospace, automotive, defense, and energy. While metal spinning is versatile and compatible with a wide range of materials, working with special alloys—such as high-strength, high-temperature, or corrosion-resistant alloys like Hastelloy, Inconel, titanium, and magnesium alloys—presents unique challenges. These difficulties stem from the complex mechanical, thermal, and metallurgical properties of special alloys, which demand advanced techniques, precise control, and specialized Read more

Hydroforming Magnetic and Rotary Pumps

Hydroforming, magnetic drive systems, and rotary pump technologies represent advanced engineering solutions that have significantly impacted various industries, including chemical processing, medical device manufacturing, automotive, and aerospace. This article provides a comprehensive exploration of hydroforming as applied to magnetic and rotary pumps, delving into their principles, designs, applications, advantages, limitations, and future prospects. The tone and structure aim to mirror the rigor and neutrality of a scientific encyclopedia, with detailed comparisons presented in tables to enhance clarity and utility. Introduction Hydroforming is a specialized metal-forming process that utilizes high-pressure hydraulic fluid to shape ductile metals, such as aluminum, stainless steel, and titanium, into complex geometries. The process is particularly valued for producing lightweight, high-strength components with minimal material waste, making Read more

What Is Large Basin CNC Metal Spinning

Large basin CNC metal spinning is a sophisticated manufacturing process used to create large, axisymmetric, seamless metal components, typically with diameters exceeding 1 meter (39 inches) and often used in industries such as aerospace, energy, chemical processing, and industrial manufacturing. This process involves rotating a flat metal disc or preformed blank at high speeds on a computer numerically controlled (CNC) spinning lathe while applying localized pressure with a roller tool to shape the metal over a mandrel or chuck into a desired form, such as a deep basin, hemispherical dome, or cylindrical vessel. The term “large basin” refers to the substantial size and volume of the components produced, which are often used as tanks, pressure vessels, or structural parts requiring Read more

The Importance of Shell Nosing in Metal Spinning

Metal spinning, also known as spin forming or metal turning, is a metalworking process that transforms a flat metal disc or tube into axially symmetric parts through high-speed rotation and localized plastic deformation. This ancient technique, with roots traceable to Ancient Egypt, has evolved into a sophisticated manufacturing method used across industries such as aerospace, automotive, and defense. A critical yet often underexplored aspect of metal spinning is shell nosing, a specialized process that involves forming the open end of a spun metal shell into a tapered, rounded, or otherwise contoured shape. Shell nosing enhances the structural integrity, functionality, and aesthetic appeal of spun components, making it a pivotal operation in the production of high-precision parts like artillery shells, rocket Read more

Development of Metal Spinning Machines for Noncircular Shapes

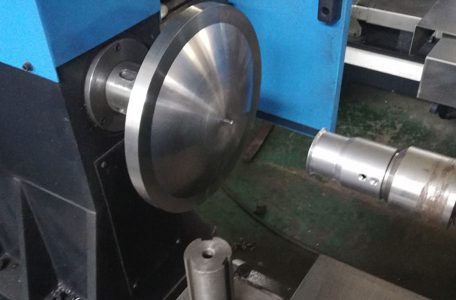

Metal spinning, also known as spin forming or metal turning, is a metalworking process that transforms a flat metal disc or tube into axially symmetric components by rotating it at high speeds while applying localized pressure. This technique is widely used to produce shapes such as cones, cylinders, hemispheres, and hemi-ellipsoids, which are essential in industries like aerospace, automotive, and manufacturing. The mandrel-free metal spinning process, a modern advancement, eliminates the need for a solid mandrel, reducing tooling costs, lead times, and material usage while increasing flexibility in forming complex geometries. This article explores the mandrel-free metal spinning process specifically for forming hemispherical and hemi-ellipsoidal parts from low carbon steel sheets, delving into its principles, mechanics, process parameters, material behavior, Read more

Forming of Hemispherical and Hemi-Ellipsoidal Parts of Low Carbon Steel Sheet by Mandrel-Free Metal Spinning Process

Metal spinning, also known as spin forming or metal turning, is a metalworking process that transforms a flat metal disc or tube into axially symmetric components by rotating it at high speeds while applying localized pressure. This technique is widely used to produce shapes such as cones, cylinders, hemispheres, and hemi-ellipsoids, which are essential in industries like aerospace, automotive, and manufacturing. The mandrel-free metal spinning process, a modern advancement, eliminates the need for a solid mandrel, reducing tooling costs, lead times, and material usage while increasing flexibility in forming complex geometries. This article explores the mandrel-free metal spinning process specifically for forming hemispherical and hemi-ellipsoidal parts from low carbon steel sheets, delving into its principles, mechanics, process parameters, material behavior, Read more

Manufacturing of Gas Turbine Engine Parts via Metal Spinning

The manufacturing of gas turbine engine components is a highly specialized field within aerospace engineering, requiring precision, durability, and adherence to stringent performance standards. Among the various fabrication techniques employed, metal spinning stands out as a versatile and cost-effective process for producing rotationally symmetric parts, such as compressor housings, combustor liners, and turbine shrouds. Metal spinning, also known as spin forming or spinning, is a metalworking process that shapes a flat metal disc or tube into a desired geometry by rotating it at high speed and applying localized pressure with a tool. This article provides a comprehensive exploration of the metal spinning process as applied to gas turbine engine parts, covering its principles, materials, equipment, process parameters, advantages, limitations, and Read more

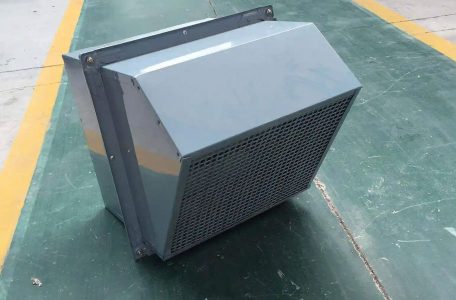

Ventilation Shell in Real Estate and Architecture

In the domains of real estate and architecture, the term “ventilation shell” is not a standard or widely recognized phrase within the conventional lexicon of building design or property development. However, for the purposes of this article, we interpret “ventilation shell” as a conceptual framework referring to the structural and systemic components of a building designed to facilitate ventilation, encompassing the building envelope, mechanical systems, and architectural features that collectively ensure adequate air exchange and quality. This interpretation aligns with the principles of indoor air quality management, energy efficiency, and occupant comfort, which are central to modern architectural practice. The ventilation shell, in this context, can be understood as the integrated assembly of elements that govern airflow, including walls, windows, Read more

Aluminum Drum Shell Fabrication: A Comprehensive Scientific Exploration

American Standard Heating, Ventilation, and Air Conditioning (HVAC) parts are integral components of one of the most recognized brands in the HVAC industry, known for producing reliable, energy-efficient, and durable systems for residential and light commercial applications. Founded in 1929 through the merger of the Standard Sanitary Manufacturing Company and the American Radiator Company, American Standard has evolved into a leading manufacturer of HVAC equipment, offering a wide range of parts that support air conditioners, heat pumps, furnaces, air handlers, and indoor air quality systems. This article explores the technical specifications, functionality, and comparative analysis of American Standard HVAC parts, emphasizing their role in modern climate control systems. Historical Context and Brand Evolution American Standard’s journey in the HVAC sector Read more

Deep Spinning Of Sheet Metals

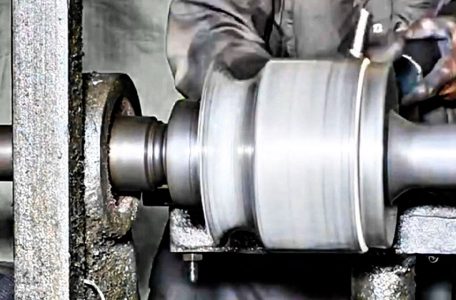

Deep spinning of sheet metals is a highly specialized metal-forming process rooted in the broader domain of spin forming or metal spinning, a technique that has been employed for centuries to shape ductile metals into axially symmetric components. This process, often conducted on a lathe or a dedicated spinning machine, involves the incremental deformation of a flat metal sheet or blank into a desired three-dimensional geometry, typically using a combination of rotational motion and controlled pressure from a forming tool. Unlike conventional spinning, which is generally limited to shallow or moderately deep parts, deep spinning refers to the production of components with significant depth-to-diameter ratios, often exceeding 1:1, where the final shape requires substantial material flow and deformation. This article Read more

Why Heat Up Metal Before Spinning

Metal spinning, a sophisticated and versatile metalworking process, involves the transformation of flat metal discs or tubes into axially symmetric components through the application of controlled force. This technique, often executed on a lathe or specialized spinning machine, relies on the ductility and malleability of the metal to achieve the desired shape. One critical aspect of this process that significantly influences its success is the decision to heat the metal prior to spinning. Heating metal before spinning enhances its workability, reduces mechanical stresses, and enables the production of complex geometries that would otherwise be unattainable under cold-working conditions. This article explores the scientific, metallurgical, and practical reasons for preheating metal in the spinning process, delving into the physics of deformation, Read more

CNC Turning of Oblique Ellipses

CNC (Computer Numerical Control) turning is a precision machining process that shapes a rotating workpiece using a stationary cutting tool. While CNC turning is commonly used to produce cylindrical parts, advanced techniques enable the creation of complex geometries, such as ellipses and, more specifically, oblique ellipses. An oblique ellipse, in this context, refers to an elliptical profile that is not aligned perpendicularly or parallel to the lathe’s rotational axis but is instead oriented at an angle, introducing unique challenges in machining. This article provides a comprehensive exploration of the methods, tools, programming strategies, and applications of CNC turning for oblique ellipses, emphasizing the technical intricacies, mathematical foundations, and practical considerations. The discussion is structured to offer a scientific and systematic Read more

Application of Spinning Technology in Processing Complex Sheet Metal Parts for Automobiles

Metal spinning blanks are fundamental components in the metalworking process known as metal spinning, a technique used to form axially symmetric, hollow metal parts by rotating a flat or preformed metal disc or tube at high speed and applying localized force to shape it over a mandrel. These blanks serve as the starting material, typically consisting of sheet metal or tubular stock, and their properties—such as material composition, thickness, diameter, and surface condition—directly influence the feasibility, quality, and efficiency of the spinning process. Metal spinning, also referred to as spin forming or metal turning, is a versatile manufacturing method with applications ranging from artisanal crafts to high-precision industrial components, including aerospace nose cones, cookware, and musical instrument bells. This article Read more

Numerical Modelling, Validation, and Analysis of Multi-Pass Sheet Metal Spinning Processes

How to Roll the Edge of Metal Spinnings

Metal spinning, a centuries-old craft rooted in both artisanal and industrial traditions, involves the shaping of sheet metal into axially symmetrical forms through controlled deformation over a rotating mandrel. Among the myriad finishing techniques applied to spun metal components, rolling the edge—also referred to as edge rolling, beading, or curling—stands out as a critical process that enhances both the functionality and aesthetics of the final product. This article explores the multifaceted process of rolling the edge of metal spinnings, delving into its history, principles, techniques, equipment, material considerations, and applications. Through a comprehensive examination, supported by comparative tables, this discussion aims to provide a thorough understanding of edge rolling in the context of modern manufacturing and traditional craftsmanship. Historical Context Read more

An industrial hopper is a critical piece of equipment widely utilized across various industries for the storage, handling, and controlled dispensing of bulk materials. These materials can range from powders and granules to larger aggregates, such as grains, coal, sand, cement, or even industrial byproducts like ash or slag. Hoppers are engineered to facilitate the efficient movement of materials in industrial processes, serving as intermediary storage units that ensure a consistent supply to downstream equipment, such as conveyors, mixers, or processing machinery. Their design and functionality are rooted in principles of material science, mechanical engineering, and fluid dynamics, making them indispensable in sectors like manufacturing, agriculture, mining, construction, and chemical processing. The concept of a hopper dates back to ancient Read more

Spinning Trapezoidal Internal Gears

Spinning trapezoidal internal gears is a sophisticated process used in the manufacturing of gears with specific geometries, where the tooth profile is not circular but trapezoidal. This process is employed primarily in industries where precision, durability, and the ability to operate under high stress are paramount. Trapezoidal internal gears are crucial components in machines that require high torque and reliable performance, such as in the automotive, aerospace, and heavy machinery sectors. The use of the spinning process to manufacture these gears allows for greater flexibility in terms of geometry, precision, and material efficiency compared to traditional gear cutting methods. Internal gears are gears that have teeth cut on the inside of a cylindrical surface, and trapezoidal profiles are used in Read more

The Design of a Flexible Fixture for Positioning in the Processing of Digital Electronic Spinning Parts

The design and development of flexible fixtures for positioning in the processing of digital electronic spinning parts represent a critical advancement in modern manufacturing technology. As industries increasingly rely on precision-engineered components for digital electronics—such as those used in smartphones, computers, and other advanced devices—the need for adaptable, efficient, and accurate fixtures has grown exponentially. This article explores the intricacies of designing such a fixture, delving into its mechanical principles, material considerations, adaptability to spinning processes, and integration with digital electronic part production. Through detailed explanations, comparisons, and technical tables, this discussion aims to provide a comprehensive resource for engineers, researchers, and manufacturers seeking to optimize the production of spinning parts in the digital electronics sector. Flexible fixtures are specialized Read more