Hot Spinning Forming Method of Heterogeneous Titanium Alloy Thin-Walled Tubes in Cross-Phase Regions

The Effect of Cold Spinning Processing Thinning on the Strength of Elliptical Heads

CNC (Computer Numerical Control) spinning, also known as metal spinning, is a metalworking process where a sheet or tube of metal is rotated at high speed and formed into a symmetrical part by pressing against a spinning mandrel. This process, traditionally performed manually by skilled artisans, has evolved significantly with the advent of CNC technology, enabling automated, precise, and repeatable production. CNC spinning software plays a critical role in this evolution by providing the necessary tools for designing, simulating, and controlling the spinning process. These software solutions enable manufacturers to create complex shapes with high accuracy, reduce material waste, and increase production speed, making CNC spinning an integral part of various industries, including aerospace, automotive, and consumer products.The success of Read more

High-Speed Liquid-Filled Spinning of Micro-Grooves on the Inner Wall of Copper Heat Pipes

The Influence of Process Parameters on the High-Pressure Spinning Process of Cylindrical Parts

Wall Thickness Variation of Large Complex Thin-Walled Shells During Multi-Pass Spinning

Top 20 Furniture Parts Used for Metal Spinning

Top 20 Metal Spinning for HVAC

Top 20 Musical Instrument Parts for Metal Spinning

CNC Spinning in Metal Yo-Yo Manufacturing

What Are the Limitations of Metal Spinning?

Steel Plate Flatness Tolerance: The Choice When You Have Flatness Tolerance for Steel Plates

Different Types of Iron: Introduction, Properties, and Uses

Why Does the Wall Thickness Decrease During Spinning?

Metal Spinning vs. Low Pressure Casting

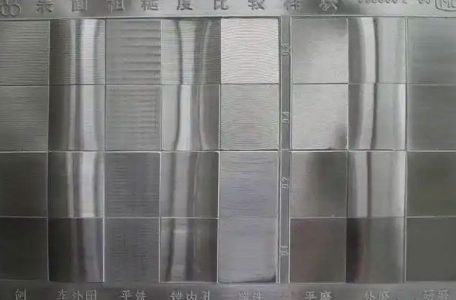

How to Measure Surface Roughness

Hemispheres Spinning vs. Hemispheres Deep Drawing

Shear Spinning 101: Define and How Do Shear Spinning Works?

Auxiliary Forming Technology Of Metal Spinning

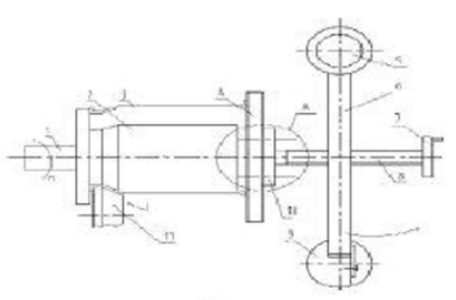

A brief discussion on the technical improvement of spinning forming equipment

Application of Stainless Steel Deep Drawing Oil in Spinning Processing

How Fast Does a Metal Lathe Spin?

Who Invented Metal CNC Spinning?

Metal spinning, also known as spin forming or metal turning, is a metalworking process that dates back several centuries. It involves rotating a metal disc or tube on a lathe and shaping it using various tools to form axially symmetric parts. This traditional technique has been transformed significantly with the advent of Computer Numerical Control (CNC) technology, leading to the modern process known as metal CNC spinning. Metal CNC spinning combines the precision of CNC machining with the traditional art of metal spinning. This advancement has revolutionized the manufacturing of symmetrical metal parts, allowing for greater accuracy, repeatability, and efficiency. The invention and evolution of metal CNC spinning is a fascinating story that intertwines with the broader development of metalworking Read more

Monel Spinning vs. Monel Turning

Analysis of the Effect of Reduction Ratio on the Distribution of Rotational Pressure in Cylindrical Components

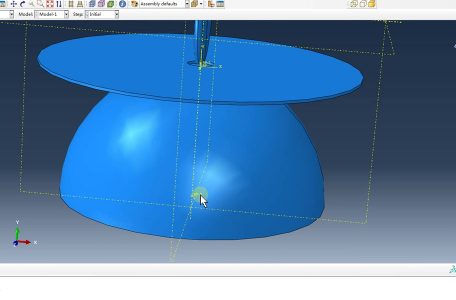

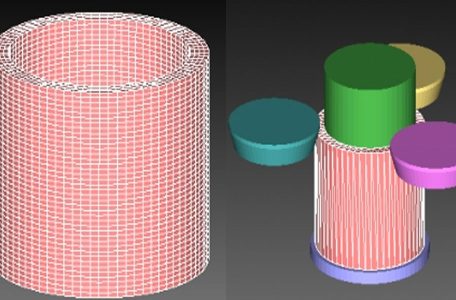

Spinning is a process method that uses a tool to continuously apply pressure to a very small part of the workpiece to gradually shape it. Spinning deformation is a local progressive deformation, and its progressiveness is similar to swing rolling. According to the deformation characteristics of spinning, the spinning process can be divided into two categories: ordinary spinning and high-power spinning [1]. Using software to simulate the high-power spinning process can clearly obtain the required data and effectively prevent defects in actual production. Software modeling and simulation In this paper, the metal forming software Simufact is used to simulate the high-power spinning process. The simulation process ignores the influence of gravity and metal inclusions, and ignores the influence of temperature Read more

Spinning of Curved Busbar Aluminum Alloy Cylindrical Parts

In order to machine 3 mm thick large-size cylindrical Al alloy part with curvilinear generatrix followed by straight- walled section, power-conventional spinning combination method supplemented with heat spinning via horizontal CNC spinning machine was explored through process tests, namely, power spinning of the conical curve section at the small end fol-lowed by multi-pass heat conventional spinning. It has been proved that power-conventional spinning combination method is feasible for the machining of large-size Al alloy cylindrical parts with cone-curved profile. Part blank design, necking amount of conventional spinning and part expanding are primary factors affecting the success of the above spinning processes. A certain aluminum alloy cylindrical part is a large-sized cylindrical part with a small taper curved generatrix connected to Read more

Die-Less Spinning of Asymmetric Workpieces

A metal lathe is a fundamental machine tool used in metalworking for shaping metal and other materials through rotational cutting. It has been essential in manufacturing and engineering for over a century, evolving from manual lathes to sophisticated computer-controlled systems. The speed at which a metal lathe spins, or its rotational speed, is a critical parameter that influences machining efficiency, surface finish, tool wear, and overall productivity. This article provides a comprehensive overview of the factors affecting lathe speed, the types of lathes, and the implications of different speeds in metalworking. Historical Context Of Metal Lathe Rotation Speeds The metal lathe’s origins can be traced back to ancient Egypt and Greece, where primitive forms of the lathe were used for Read more