Servo spinning, a precision metal-forming process, is widely utilized in industries such as aerospace, automotive, and energy for producing high-strength, lightweight, and complex-shaped components. The process involves the incremental deformation of a rotating metal blank over a mandrel using a roller tool controlled by a servo-driven system. Multi-pass servo spinning, characterized by multiple deformation cycles, enhances dimensional accuracy and material properties but introduces complex material behaviors, notably elastic rebound and reloading. These phenomena, driven by the material’s elastic-plastic response, pose significant challenges to achieving precise control over geometry and mechanical properties. This article provides a comprehensive exploration of the theoretical modeling of elastic rebound-reloading behavior in multi-pass servo spinning and proposes adaptive compensation strategies to mitigate its effects. By integrating Read more

Dynamic Modeling and Theoretical Prediction of Large Plastic Deformation in Asymmetric Spinning

Asymmetric spinning, a specialized variant of the metal spinning process, has emerged as a critical manufacturing technique for producing complex, axisymmetric components with high precision and tailored mechanical properties. Unlike conventional spinning, which typically involves symmetric deformation of a rotating workpiece under the action of a roller, asymmetric spinning introduces non-uniform deformation patterns by employing differential speeds, varying roller paths, or asymmetric tooling configurations. This process is particularly valuable in industries such as aerospace, automotive, and energy, where lightweight, high-strength components with intricate geometries are in demand. The ability to predict and control the large plastic deformation paths in asymmetric spinning is essential for optimizing process parameters, minimizing defects, and ensuring the structural integrity of the final product. This article Read more

Interfacial Shear Stability and α/β Phase Boundary Migration in Dual-Phase Titanium Alloys under Hot-Spinning Composite Loads

Dual-phase titanium alloys, such as the widely utilized Ti-6Al-4V, are cornerstone materials in high-performance applications, particularly in aerospace, biomedical, and automotive industries, due to their exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand elevated temperatures. These alloys typically consist of a hexagonal close-packed (HCP) α phase and a body-centered cubic (BCC) β phase, with their mechanical properties heavily influenced by the interplay between these phases at their interfaces. The α/β phase boundary, a critical microstructural feature, governs deformation behavior, phase transformation kinetics, and overall material performance under complex loading conditions. Hot-spinning, a thermomechanical processing technique, subjects these alloys to composite loads—combining shear, tensile, and compressive stresses at elevated temperatures—making it an ideal process to study interfacial shear stability and Read more

Formation Mechanism and Control Strategy of Defects in Spinning Super-Large Titanium Alloys for Deep Space Exploration Structures

Titanium alloys, renowned for their exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance, have become indispensable in the aerospace industry, particularly for deep space exploration structures. Super-large titanium alloy components, such as those used in spacecraft bulkheads, fuel tanks, and structural frames, are critical for ensuring the reliability and safety of missions operating in extreme environments. The spinning process, a specialized metal-forming technique, is widely employed to fabricate these large-scale, axisymmetric components due to its ability to produce seamless, lightweight structures with high precision. However, the spinning of super-large titanium alloys is fraught with challenges, primarily due to the formation of defects that compromise structural integrity. These defects, ranging from surface cracks to internal voids, arise from complex interactions between Read more

Research on Spinning Connection Mechanism and Interface Strength Evolution Law of Dissimilar Metal Composite Materials

The development of advanced manufacturing techniques has driven significant interest in dissimilar metal composite materials, which combine the desirable properties of different metals to achieve superior mechanical, thermal, and chemical performance. These hybrid structures are critical in industries such as aerospace, automotive, and energy, where lightweight, high-strength, and corrosion-resistant materials are essential. A key challenge in the fabrication of dissimilar metal composites is achieving robust interfacial bonding, as the interface often dictates the overall mechanical integrity and performance of the composite. Among the various joining techniques, the spinning connection mechanism—a solid-state forming process—has emerged as a promising method for creating high-quality joints between dissimilar metals. This article explores the spinning connection mechanism, the evolution of interface strength, and the underlying Read more

Research on Forming Performance and Service Performance Evolution of Corrosion-Resistant Alloy Spinning Cylinders for Marine Engineering

Corrosion-resistant alloy (CRA) spinning cylinders are critical components in marine engineering, designed to withstand the harsh environmental conditions of seawater, including high salinity, fluctuating temperatures, and mechanical stresses. These cylinders, often used in applications such as hydraulic riser tensioners, piston rods, and structural supports for offshore platforms, require exceptional forming performance during manufacturing and robust service performance during their operational life. The forming process, typically involving spinning techniques, must produce components with precise geometries, high strength, and resistance to defects. Service performance, on the other hand, is governed by the alloy’s ability to resist corrosion, fatigue, and wear in marine environments, where chloride-induced pitting, crevice corrosion, and microbiologically influenced corrosion (MIC) pose significant challenges. This article comprehensively reviews the research Read more

Optimization of Process Parameters and Microstructure Evolution of Superplastic Alloys in Hot Spinning

Superplasticity is a remarkable phenomenon observed in certain polycrystalline materials, characterized by their ability to undergo extensive tensile deformation—often exceeding elongations of 400%—without necking or fracturing. This property is particularly valuable in manufacturing processes like hot spinning, where complex geometries and intricate components can be formed with high precision and minimal material waste. Hot spinning, a metal-forming technique, involves the incremental deformation of a rotating workpiece using rollers, typically at elevated temperatures, to shape materials into cylindrical or conical forms. When applied to superplastic alloys, hot spinning leverages their exceptional ductility to produce components with superior mechanical properties and refined microstructures, critical for applications in aerospace, automotive, and energy sectors. The optimization of process parameters in hot spinning of superplastic Read more

Effect of CNC Spinning Under Cryogenic Conditions on Microstructure and Properties of High-Strength Aluminum Alloy

High-strength aluminum alloys, characterized by their excellent strength-to-weight ratio, corrosion resistance, and formability, are critical materials in industries such as aerospace, automotive, and marine engineering. These alloys, including the 2xxx, 6xxx, and 7xxx series, are widely used for manufacturing complex, thin-walled components that demand high mechanical performance under extreme conditions. However, conventional forming processes, such as CNC (Computer Numerical Control) spinning at room temperature, often encounter challenges like wrinkling, cracking, and compromised mechanical properties due to the alloys’ limited ductility and high strength. To address these issues, cryogenic CNC spinning—a novel forming technique conducted at ultra-low temperatures—has emerged as a promising method to enhance the formability and mechanical properties of high-strength aluminum alloys. Cryogenic CNC spinning involves the deformation of Read more

Industrialization Research of CNC Spinning in Defense Equipment Manufacturing

Computer Numerical Control (CNC) spinning, a sophisticated metal-forming process, has emerged as a pivotal technology in the manufacturing of defense equipment. This advanced technique involves the use of computer-controlled machinery to shape metal workpieces into axially symmetric components through high-speed rotation and precise tool application. CNC spinning is distinguished by its ability to produce high-strength, lightweight, and complex geometries with exceptional precision, making it indispensable in the defense sector, where components must meet stringent performance and reliability standards. The industrialization of CNC spinning in defense equipment manufacturing represents a convergence of technological innovation, material science, and industrial engineering, driven by the need for enhanced military capabilities, cost efficiency, and rapid production scalability. The defense industry relies on CNC spinning to Read more

Application and Exploration of Spin Forming Technology in Microelectronic Packaging

Spin forming, also known as metal spinning or spin forging, is a metalworking process that involves rotating a metal blank or tube at high speed while applying localized pressure with rollers or tools to shape it into a desired form. This technique, rooted in ancient craftsmanship, has evolved into a sophisticated manufacturing method used across industries, including aerospace, automotive, and, more recently, microelectronics. Unlike traditional forming processes like stamping or forging, spin forming is an incremental process, allowing for precise control over material deformation, reduced material waste, and the ability to work with hard-to-deform alloys. Its adaptability to produce axisymmetric components with complex geometries makes it particularly appealing for advanced applications. Microelectronic packaging, on the other hand, is a critical Read more

Composite Process Research: Spinning and Micro-Nano Processing Technology

Composite materials, which combine two or more distinct constituents to achieve superior properties, have become pivotal in advancing technological applications across industries such as aerospace, biomedical engineering, electronics, and environmental remediation. Among the myriad techniques for fabricating composites, spinning processes—particularly electrospinning—and micro-nano processing technologies stand out for their ability to produce materials with tailored microstructures and enhanced functionalities. These methods leverage precise control over material morphology at the micro- and nanoscale, enabling the creation of fibers, films, and structures with unique mechanical, electrical, thermal, and chemical properties. This article provides a comprehensive exploration of the composite process research involving spinning and micro-nano processing technologies, detailing their principles, methodologies, recent advancements, and applications. By synthesizing insights from academic literature and industry Read more

Research on Computer Numerical Control (CNC) Spinning and Ultrasonic Vibration-Assisted Forming

Computer Numerical Control (CNC) spinning and ultrasonic vibration-assisted forming (UVAF) represent advanced manufacturing techniques that have transformed the metal forming industry. CNC spinning, a subset of the broader metal spinning process, employs computer-controlled machinery to shape sheet metal or tubular blanks into axisymmetric components with high precision and repeatability. Ultrasonic vibration-assisted forming, on the other hand, introduces high-frequency, low-amplitude vibrations to the forming process, reducing forming forces, enhancing surface quality, and mitigating defects. These technologies, individually and in combination, have garnered significant research attention due to their applications in aerospace, automotive, medical, and other high-precision industries. This article provides a comprehensive exploration of the historical development, theoretical foundations, technological advancements, experimental findings, and future directions of CNC spinning and UVAF. Read more

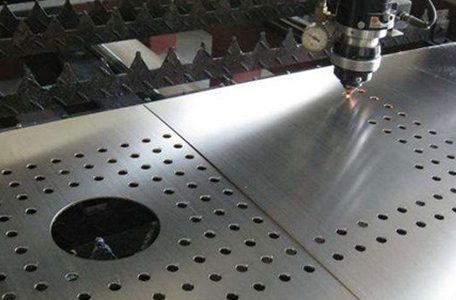

Synergistic Mechanism of Metal Spinning and Laser-Assisted Forming

Metal spinning and laser-assisted forming represent two advanced manufacturing techniques that have gained significant attention in modern industrial applications. Metal spinning, a chipless forming process, involves rotating a metal blank or preform while applying localized pressure to shape it into axisymmetric components, such as cones, cylinders, or hemispheres. Laser-assisted forming, on the other hand, leverages the precise application of laser-induced thermal energy to enhance material formability, reduce forming forces, and mitigate defects. When combined, these processes create a synergistic mechanism that enhances the capabilities of each, enabling the production of complex, high-performance components from challenging materials like titanium, high-strength steels, and nickel-based alloys. This article explores the synergistic mechanisms of metal spinning and laser-assisted forming, delving into their principles, interactions, Read more

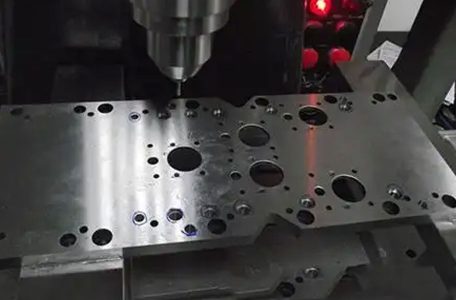

Composite Process Research of CNC Spinning and Additive Manufacturing

The integration of advanced manufacturing technologies has revolutionized the production of high-performance components across industries such as aerospace, automotive, biomedical, and energy. Among these technologies, Computer Numerical Control (CNC) spinning and additive manufacturing (AM) have emerged as pivotal processes, each offering unique capabilities in shaping materials with precision and efficiency. CNC spinning, a traditional subtractive and forming technique, excels in producing rotationally symmetric components with superior surface finishes and structural integrity. Additive manufacturing, often referred to as 3D printing, enables the fabrication of complex geometries layer by layer, offering unparalleled design flexibility and material efficiency. The convergence of these two processes—termed composite process research—seeks to harness their complementary strengths, addressing limitations inherent in each when used independently. This article provides Read more

Adaptive Optimization of Spinning Path Based on Reinforcement Learning

The optimization of spinning paths in mechanical systems, robotics, and industrial automation has long been a critical area of research, driven by the need to enhance efficiency, reduce energy consumption, and improve operational precision. Spinning path optimization involves determining the most effective trajectory for a rotating object or mechanism, such as a robotic arm, a spinning tool, or a vehicle navigating a curved path. Traditional approaches to path optimization often rely on deterministic algorithms or heuristic methods, which may struggle to adapt to dynamic environments or complex constraints. In recent years, reinforcement learning (RL), a subset of machine learning, has emerged as a powerful tool for addressing these challenges by enabling adaptive, data-driven optimization of spinning paths. Reinforcement learning is Read more

Design of Complex Component Spinning Based on Topology Optimization

Topology optimization is a mathematical method used in engineering design to optimize material distribution within a given design space, aiming to achieve the best structural performance while adhering to specific constraints such as weight, volume, or manufacturing limitations. When applied to the design of complex component spinning—a manufacturing process where a flat metal disc or tube is rotated at high speed and formed into an axially symmetric part—topology optimization offers significant potential to enhance efficiency, reduce material usage, and improve mechanical performance. This article explores the integration of topology optimization in the spinning process for complex components, delving into its theoretical foundations, practical applications, computational methodologies, and comparative analyses with traditional design approaches. The discussion is structured to provide a Read more

Relationship Between Grain Boundary Slip and Material Strength in Metal Spinning

Metal spinning, a versatile manufacturing process, involves the shaping of sheet metal into axisymmetric components through localized plastic deformation. This technique, widely used in industries such as aerospace, automotive, and medical device manufacturing, relies on the controlled application of force to deform a rotating metal blank over a mandrel. The mechanical properties of the resulting components, particularly their strength, are profoundly influenced by the microstructure of the material, with grain boundaries playing a pivotal role. Grain boundaries, the interfaces between crystalline grains in polycrystalline metals, are critical microstructural features that govern deformation mechanisms, including grain boundary slip (GBS). GBS refers to the relative sliding of adjacent grains along their boundaries under applied stress, a phenomenon that becomes particularly significant at Read more

Pad printing and screen printing represent two distinct methodologies within the broader field of industrial and commercial printing technologies. Both techniques are widely utilized across various industries for applying ink to substrates, ranging from consumer goods to specialized technical components. Pad printing, also known as tampography, involves transferring a two-dimensional image from an etched plate onto a three-dimensional object using a silicone pad. Screen printing, conversely, employs a mesh screen through which ink is forced onto a flat or semi-flat surface, creating a design via a stencil-based process. These processes, while sharing the common goal of image transfer, diverge significantly in their mechanisms, applications, and technical attributes. The origins of these printing methods reflect their evolution from traditional craftsmanship to Read more

The Ultimate Checklist for Identifying Good Welds

Welding is a critical fabrication process used to join metals or thermoplastics by applying heat, pressure, or both, resulting in a strong, permanent bond. The quality of a weld directly impacts the structural integrity, safety, and longevity of the welded component. Identifying a good weld requires a systematic evaluation of multiple factors, including visual characteristics, mechanical properties, and compliance with industry standards. This article provides a comprehensive, scientifically structured checklist for assessing weld quality, encompassing visual inspection, non-destructive testing (NDT), destructive testing, and adherence to codes and standards. Designed for welders, inspectors, engineers, and quality control professionals, this guide includes detailed explanations, comparative tables, and references to authoritative standards such as those from the American Welding Society (AWS), International Organization Read more

Matured Spinning Forming Technology for High-Performance Materials

Spinning forming technology, encompassing conventional spinning, shear spinning, and flow forming, represents a cornerstone of modern metalworking, particularly for the production of axisymmetric components. Over the past few decades, these techniques have matured significantly, driven by advancements in automation, material science, and computational modeling. Their application to high-performance materials—such as titanium alloys, aluminum alloys, magnesium alloys, nickel-based superalloys, and advanced composites—has expanded their relevance across industries like aerospace, automotive, defense, and energy. These materials, characterized by high strength-to-weight ratios, corrosion resistance, and thermal stability, pose unique challenges due to their complex deformation behaviors and limited formability at ambient temperatures. This article provides a comprehensive exploration of matured spinning forming technologies, their application to high-performance materials, and recent advancements, supported by Read more

Robotic metal spinning is an advanced manufacturing process that integrates robotic systems with the traditional technique of metal spinning, a form of plastic deformation used to produce axially symmetric or non-axisymmetric metal components. Metal spinning, also known as spin forming or spinning, involves rotating a metal blank (typically a disc or tube) at high speed while applying localized pressure with a tool—historically a manual spoon or roller—to shape the material over a mandrel. The incorporation of robotics into this process enhances precision, repeatability, and flexibility, allowing for the production of complex geometries that were once limited by the skill of human artisans. This article explores the principles, history, technological advancements, applications, and scientific underpinnings of robotic metal spinning, with a Read more

Metal spinning, also known as spin forming or spinning, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. This technique, which dates back centuries, has evolved significantly with advancements in technology and materials science, making it a critical method in modern bulk handling applications. In the context of bulk handling, metal spinning is employed to fabricate components such as containers, hoppers, silos, and chutes that are integral to industries like agriculture, mining, pharmaceuticals, and food processing. This article delves into the principles, processes, materials, applications, and scientific underpinnings of metal spinning as it pertains to bulk handling, providing a comprehensive exploration of its relevance in Read more

The Design and Implementation of HAVC System

Heating, Ventilation, and Air Conditioning (HVAC) systems are integral to modern building infrastructure, providing thermal comfort and maintaining indoor air quality (IAQ) across residential, commercial, and industrial environments. These systems regulate temperature, humidity, and air purity, ensuring occupant well-being and operational efficiency. The design and implementation of HVAC systems represent a multidisciplinary effort, combining principles of mechanical engineering, thermodynamics, fluid mechanics, and building science. Since their inception in the early 20th century, HVAC technologies have evolved significantly, driven by advancements in energy efficiency, environmental concerns, and the need for sustainable building practices. The term “HVAC” encompasses three primary functions: heating, which increases ambient temperature; ventilation, which circulates and refreshes air; and air conditioning, which cools and dehumidifies indoor spaces. In Read more

Galvanized Steel VS Stainless Steel

Galvanized steel and stainless steel are two widely utilized materials in construction, manufacturing, and various industrial applications, each prized for its unique properties and resistance to corrosion. These materials, while sharing some similarities as steel-based alloys, diverge significantly in their composition, production processes, mechanical characteristics, and suitability for specific environments. This article offers a comprehensive exploration of galvanized steel and stainless steel, delving into their metallurgical foundations, manufacturing techniques, physical and chemical properties, corrosion resistance, applications, cost considerations, environmental impacts, and long-term performance. Detailed tables are included to facilitate a scientific comparison between the two materials. Steel, at its core, is an alloy of iron and carbon, with trace amounts of other elements such as manganese, silicon, and phosphorus often Read more

CNC Spinning of Large Center Distance Arc Cam

Computer Numerical Control (CNC) spinning is an advanced manufacturing process that leverages automated machinery to form metal into complex shapes through rotational deformation. Among its many applications, the spinning of large center distance arc cams represents a specialized subset of this technology, blending precision engineering with sophisticated control systems. This article explores the principles, processes, machinery, and scientific underpinnings of CNC spinning as applied to large center distance arc cams, offering a detailed examination of its mechanics, applications, and comparative advantages. Historical Context and Evolution of CNC Spinning The origins of metal spinning trace back to ancient craftsmanship, where artisans manually shaped metal over rotating molds using rudimentary tools. This labor-intensive process evolved significantly with the Industrial Revolution, which introduced Read more

Metal Spinning Tolerance vs Stamping Tolerance

Top 20 Metal Spinning Parts for Electronics

Recent Advances in China Metal Spinning Technology

When spinning various thin-walled cross-section products, the main purpose of spinning is to change the shape of the slab, and the thickness of the slab changes little. This type of spinning is called ordinary spinning. The basic methods of ordinary spinning are: deep drawing spinning (drawing spinning), shrinking spinning (shrinking spinning) and expansion spinning (expanding spinning). What Is Deep drawing spinning Drawing spinning is a forming process that uses radial drawing as the main body to reduce the diameter of the blank (sheet or prefabricated part). It can also be said that it is similar to deep drawing, but it uses a core mold instead of a punch, and a spinning wheel instead of a die. It is the most Read more