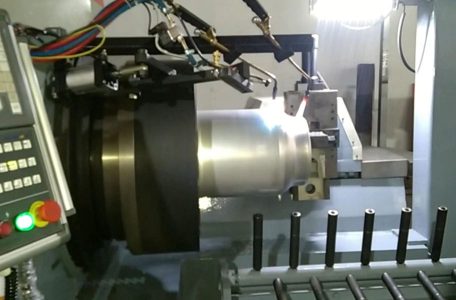

Spin Machining (commonly referred to as metal spinning, spin forming, or spinning) is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. This technique, rooted in ancient craftsmanship and refined through modern engineering, leverages the principles of plastic deformation to shape materials without removing significant amounts of material, distinguishing it from subtractive manufacturing methods like milling or turning. Spinning machining is widely utilized in industries such as aerospace, automotive, and consumer goods manufacturing, producing components ranging from cookware to rocket nose cones. This article explores the history, principles, techniques, materials, equipment, applications, and comparative analyses of spin machining, providing a detailed scientific overview of the process. Read more

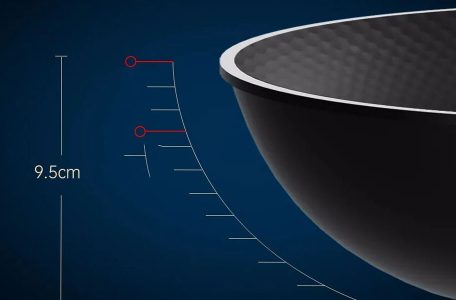

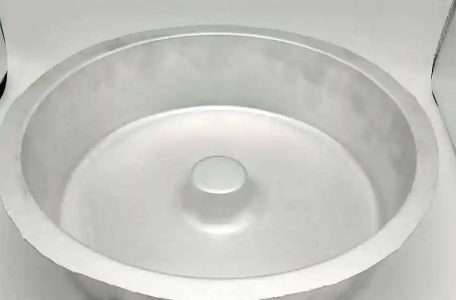

How to Spin Sheet Metal Bowls

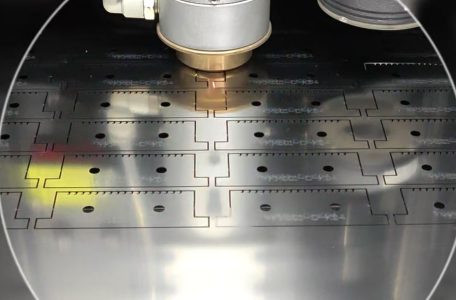

Sheet metal spinning, also known as metal spinning or spin forming, is a metalworking process by which a flat metal disc or tube is rotated at high speed and formed into an axially symmetric part, such as a bowl, using a combination of rotational force and pressure applied via specialized tools. This technique, rooted in ancient craftsmanship yet refined through modern engineering, allows for the creation of seamless, durable, and aesthetically pleasing sheet metal bowls with applications ranging from industrial components to decorative household items. The process is distinct from other forming methods, such as deep drawing or stamping, due to its reliance on incremental deformation and its ability to produce complex geometries with minimal tooling costs. This article provides Read more

How to Use Metal Spinning to Create Custom Copper Post Caps

Metal spinning, also known as spin forming or metal turning, is a metalworking process used to create axially symmetric parts by rotating a metal disc or tube at high speed and shaping it over a mandrel. This technique has been employed for centuries, evolving from manual craftsmanship to a sophisticated industrial process aided by modern machinery, such as CNC (Computer Numerical Control) lathes. One of its many applications is the production of custom copper post caps, which serve both functional and aesthetic purposes in architectural and outdoor settings. Copper post caps, typically used to protect wooden fence or deck posts from weathering while enhancing visual appeal, benefit from the ductility and corrosion resistance of copper, making metal spinning an ideal Read more

How To Custom Round Stainless Steel Hoppers

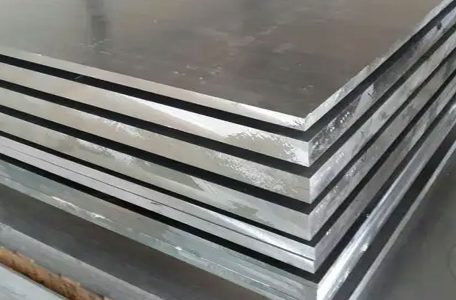

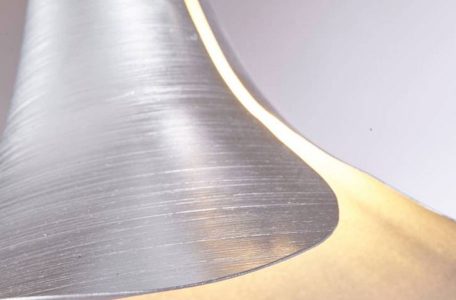

Textured Aluminum Sheet Metal

Textured aluminum sheet metal is a versatile and widely utilized material in various industries, ranging from architecture and automotive manufacturing to aerospace engineering and consumer goods production. Characterized by its distinctive surface patterns, enhanced mechanical properties, and aesthetic appeal, textured aluminum sheet metal represents a specialized form of aluminum that has undergone specific processing techniques to achieve its unique physical and chemical attributes. This article provides an in-depth exploration of textured aluminum sheet metal, delving into its composition, manufacturing processes, types, properties, applications, and comparative analyses with other materials. Through a detailed scientific lens, we aim to elucidate the significance of this material in modern engineering and design contexts. Aluminum, a lightweight, durable, and corrosion-resistant metal, serves as the foundational Read more